Description

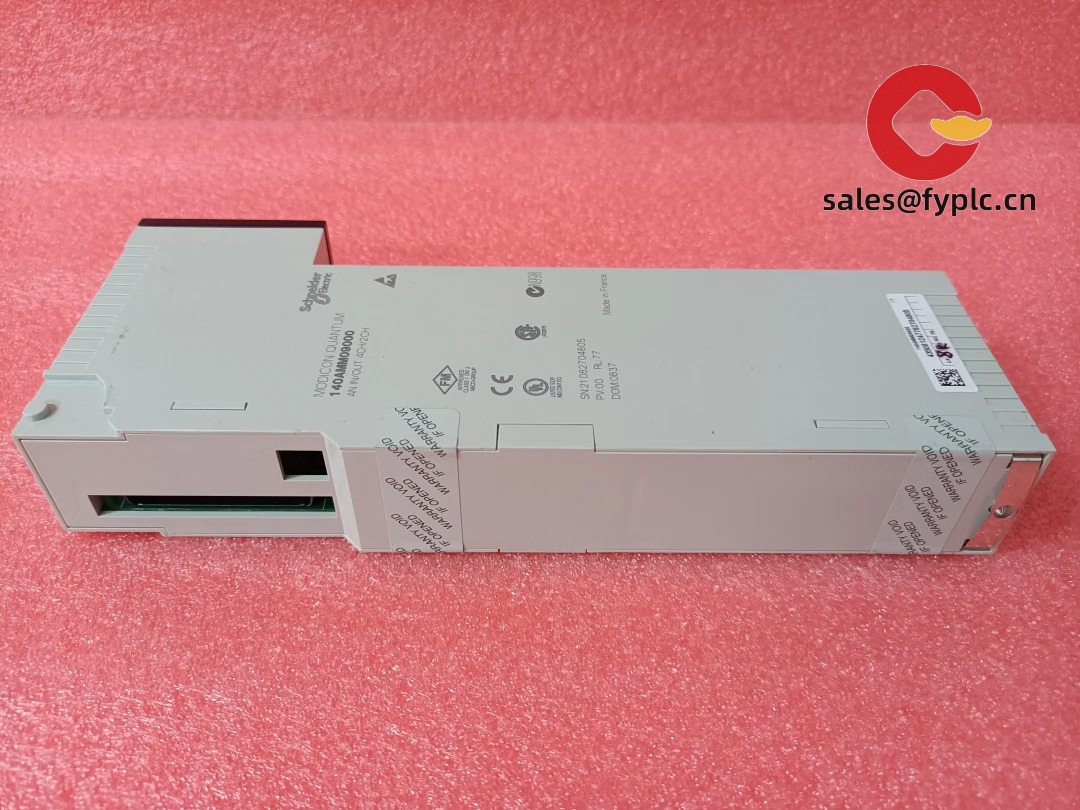

Schneider Electric 140AMM09000 – Modicon Quantum Mixed Analog I/O Module for Process Control

The Schneider Electric 140AMM09000 is a mixed analog I/O module for the Modicon Quantum platform, designed to bring both voltage and current process signals into the rack and send analog commands back out. From my experience, maintenance teams choose this card when they want clean 4–20 mA loops alongside 0–10 V references without spreading points across multiple modules. You might notice the familiar Quantum mechanics—front terminal block, clear labeling—which typically makes commissioning and swap‑outs fast during short outages.

Company’s Order Placement Process and Guarantees

- The warranty period is 365 days

- Delivery time: 1 week for in-stock; no more than one month at the latest

- Payment method: 50% advance payment, full payment for delivery

- Express delivery methods: FedEx, UPS, DHL

- Pre‑shipment checks: functional/visual inspection; ESD‑safe, shock‑resistant packing

Key Features

- Mixed analog I/O on one card – Combine standard process inputs and outputs (voltage/current) in a single Quantum slot to save space.

- Quantum backplane integration – Direct, high‑reliability exchange with the CPU and station power via the rack.

- Channel‑parameterizable – Ranges and filtering set in Control Expert/Unity Pro (or Concept on older systems) for tidy project management.

- Noise‑resilient design – Input conditioning that, in many cases, keeps long 4–20 mA runs stable with proper shielding and grounding.

- Service‑friendly terminal block – Front wiring stays put while the module is swapped, which typically shortens downtime.

Technical Specifications

| Brand / Model | Schneider Electric 140AMM09000 |

| System Family | Modicon Quantum – Mixed Analog I/O Module |

| HS Code | 8538.90 – Parts for electrical control equipment (final classification may vary by country) |

| Power Requirements | Supplied via Quantum backplane; no separate external supply on the module |

| Signal Input/Output Types | Analog voltage (e.g., 0…10 V) and current (e.g., 0/4…20 mA) inputs and outputs; channel‑parameterizable |

| Communication Interfaces | Modicon Quantum backplane to CPU; configuration via Control Expert/Unity Pro (Concept on legacy) |

| Installation Method | Single‑slot plug‑in module; front removable terminal block for field wiring |

| Operating Temperature | Typically 0…+60 °C (cabinet‑installed; non‑condensing) |

Application Fields

I often see the 140AMM09000 used where a Quantum rack needs both analog sensing and analog commands in the same slot:

- Water & wastewater – 4–20 mA transmitters in, 4–20 mA valve/drive setpoints out from compact panels.

- Chemicals & refining – mixed voltage/current loops for skid controls and dosing packages.

- Power & utilities – boiler/BOP analog feedback with analog control signals routed locally.

- Food & beverage – space‑constrained lines where one card handles both sensing and actuation references.

A controls tech told me last month, “We moved the terminal block over, set the ranges in Unity, and both the 4–20 mA loops and the 0–10 V reference came up steady.” That’s been the usual experience when wiring is clean and shields are bonded properly.

Advantages & Value

- Reliability – Stable readings and outputs for 24/7 duty when EMC practices are followed.

- Compatibility – Native Quantum mechanics and diagnostics minimize engineering changes.

- Cost savings – One module for mixed analog I/O often reduces rack footprint and spares count.

- Support – We can help confirm ranges, scaling, and terminal mapping before your window to reduce risk.

- Lead‑time clarity – Practical deliveries aligned with outage planning.

Installation & Maintenance

- Panel standards: Clean, ventilated cabinet; ambient typically 0…60 °C; non‑condensing.

- Wiring: Use twisted, shielded pairs for analog; separate from motor/VFD cables; bond shields at the panel end.

- Commissioning: Parameterize each channel (range, filter) in Control Expert/Unity; verify scaling with a loop calibrator.

- ESD & handling: Strap to ground; handle by edges; seat the module fully to ensure backplane engagement.

- Routine care: Periodic terminal re‑torque, dust removal, and quick noise/offset checks during planned stops.

Quality & Certifications

- Built under Schneider Electric quality systems (typically ISO 9001 aligned).

- CE marking for EMC/safety; many Quantum modules are UL/cUL Recognized.

- RoHS compliance by series generation; we can confirm by part/serial.

- Warranty: 365 days repair/replace coverage from delivery.

Reviews

There are no reviews yet.