Description

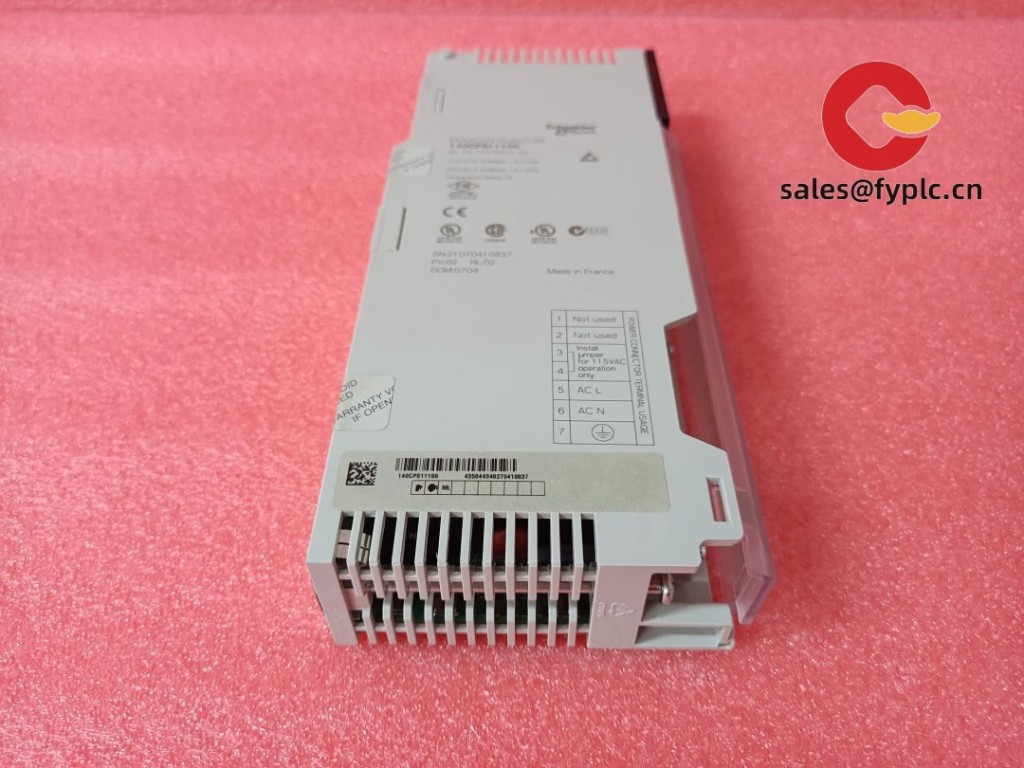

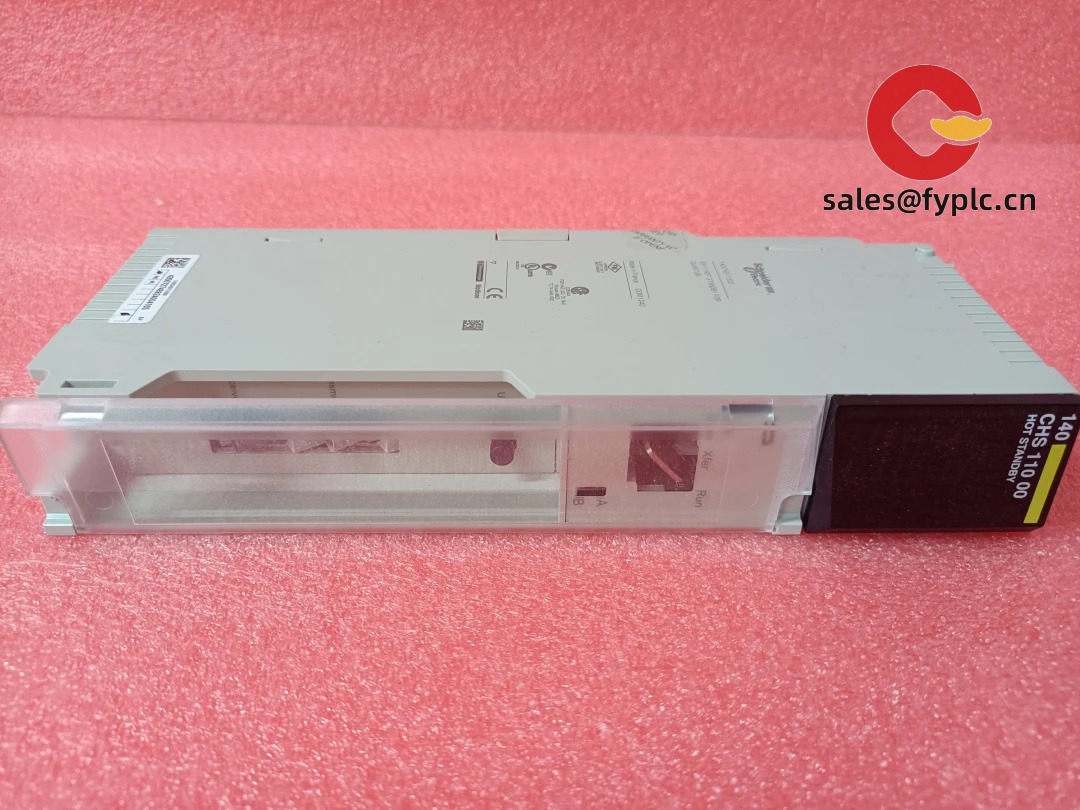

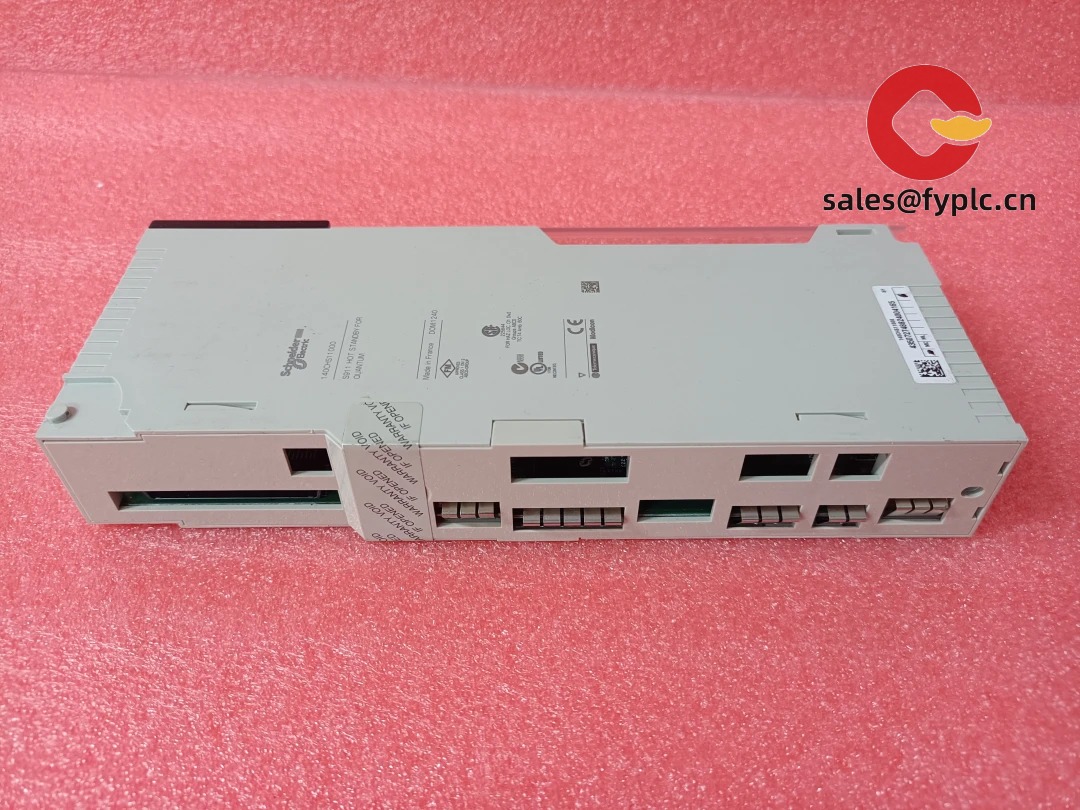

Schneider Electric 140CHS11000 – Modicon Quantum Hot Standby Module for CPU Redundancy

The Schneider Electric 140CHS11000 is the Hot Standby (HSBY) module for Modicon Quantum racks. In practical terms, it links a primary and a standby Quantum CPU so the standby mirrors the primary and can take over automatically if there’s a fault. From my experience, it’s the cleanest path to CPU redundancy on brownfield Quantum systems—you keep your I/O strategy and cabinet layout, add the HSBY link, and gain predictable switchover behavior.

Company’s Order Placement Process and Guarantees

- The warranty period is 365 days

- Delivery time: 1 week for in-stock; no more than one month at the latest

- Payment method: 50% advance payment, full payment for delivery

- Express delivery methods: FedEx, UPS, DHL

- Pre‑shipment checks: visual/label verification and basic functional check; ESD‑safe, shock‑resistant packing

Key Features

- CPU redundancy for Quantum – Creates a primary/standby pair so control keeps running after a CPU fault.

- Deterministic switchover – Standby tracks the primary in real time; switchover is typically fast and predictable when the link is healthy.

- Backplane integration – Communicates directly with the CPU over the Quantum backplane; no extra gateways.

- Status & diagnostics – Front LEDs and clear states (Primary/Standby/Sync) help maintenance verify redundancy at a glance.

- Like‑for‑like retrofit – Fits standard Quantum racks; in many cases no cabinet modification is needed.

Technical Specifications

| Brand / Model | Schneider Electric 140CHS11000 |

| Function | Modicon Quantum Hot Standby (HSBY) module for CPU redundancy |

| HS Code | 8538.90 – Parts for electrical control equipment (final classification may vary by country) |

| Power Requirements | Powered via Quantum backplane (no separate external power on module) |

| Communication Interfaces | Dedicated Hot Standby sync/link between two 140CHS11000 modules; backplane link to CPU |

| Signal I/O Types | Redundancy status/control over backplane and HSBY link; no process I/O terminals on the module |

| Installation Method | Single‑slot Quantum plug‑in; one module per rack in the redundant pair (matching slot positions recommended) |

| Operating Temperature | Typically 0…+60 °C (cabinet‑installed; non‑condensing) |

| Dimensions & Weight (approx.) | Quantum single‑slot format; ~0.3–0.5 kg |

Application Fields

Plants use the 140CHS11000 wherever process uptime is non‑negotiable and the Quantum base should be preserved:

- Power generation and utilities – redundant control of boiler/BOP and balance‑of‑plant systems.

- Oil & gas / petrochem – hot standby CPUs for continuous units and critical interlocks.

- Water & wastewater – plant‑wide SCADA/PLC islands that must ride through a CPU failure.

- Pharma and food – validated Quantum cabinets where like‑for‑like redundancy eases change control.

A controls engineer summed it up well: “We paired two Quantum racks with 140CHS11000, ran a forced failover, and the process held steady.” That’s typically the outcome when both racks are matched and the link is wired correctly.

Advantages & Value

- Reliability – Automatic switchover keeps loops alive through CPU faults or maintenance.

- Compatibility – Native to Quantum; preserves existing I/O, wiring, and most project structures.

- Cost savings – Adds redundancy without a platform migration; reduces outage risk.

- Support – We can help review slot layout, firmware alignment, and HSBY link checks before shutdown.

- Lead‑time certainty – Practical deliveries aligned with outage windows.

Installation & Maintenance

- Rack pairing: Use two Quantum racks with identical slot layouts; install one 140CHS11000 per rack in the same slot.

- HSBY link: Route the dedicated standby link cleanly between racks; avoid motor/VFD cable trays; verify link LEDs.

- Project setup: Enable Hot Standby in Control Expert/Unity Pro; match CPU firmware and module revisions.

- Testing: Perform a controlled switchover test (primary power pull or CPU stop) during commissioning to validate behavior.

- ESD & handling: Strap to ground; seat the module firmly to ensure full backplane engagement.

- Routine care: Periodic dust cleaning, connector torque checks, and a quick redundancy health check in diagnostics.

Quality & Certifications

- Manufactured under Schneider Electric quality systems (ISO 9001 aligned).

- CE marking for EMC/safety; many Quantum modules are UL/cUL Recognized.

- RoHS compliance by series generation; confirmable by part/serial if needed.

- Warranty: 365 days repair/replace coverage from delivery.

Reviews

There are no reviews yet.