Description

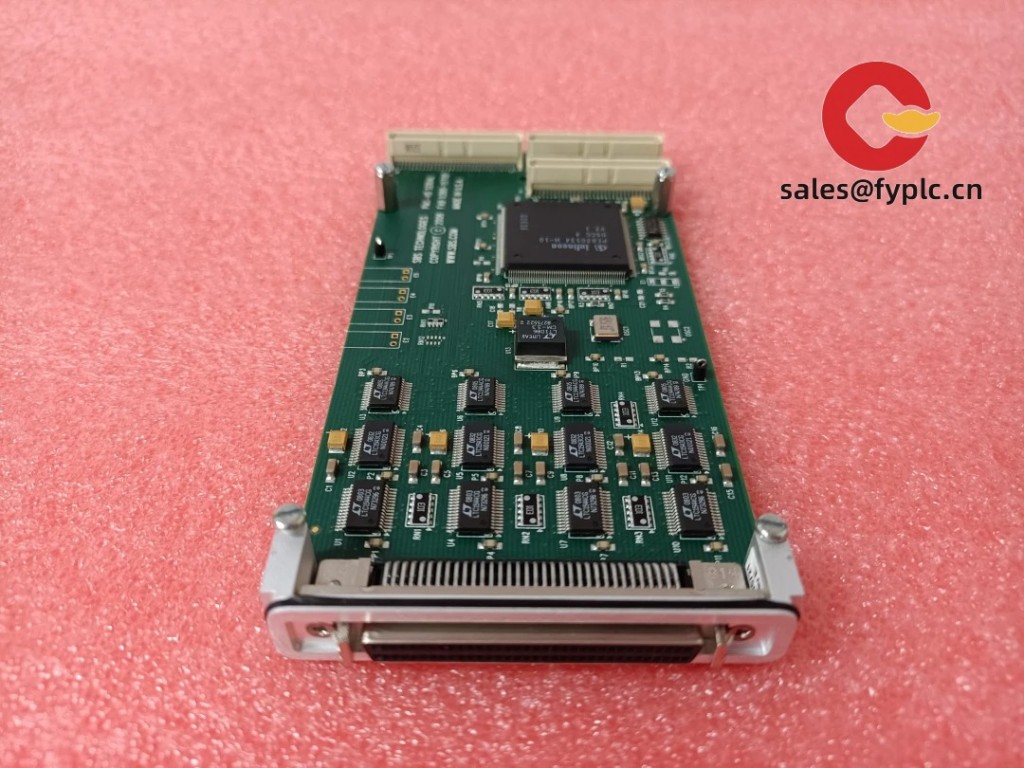

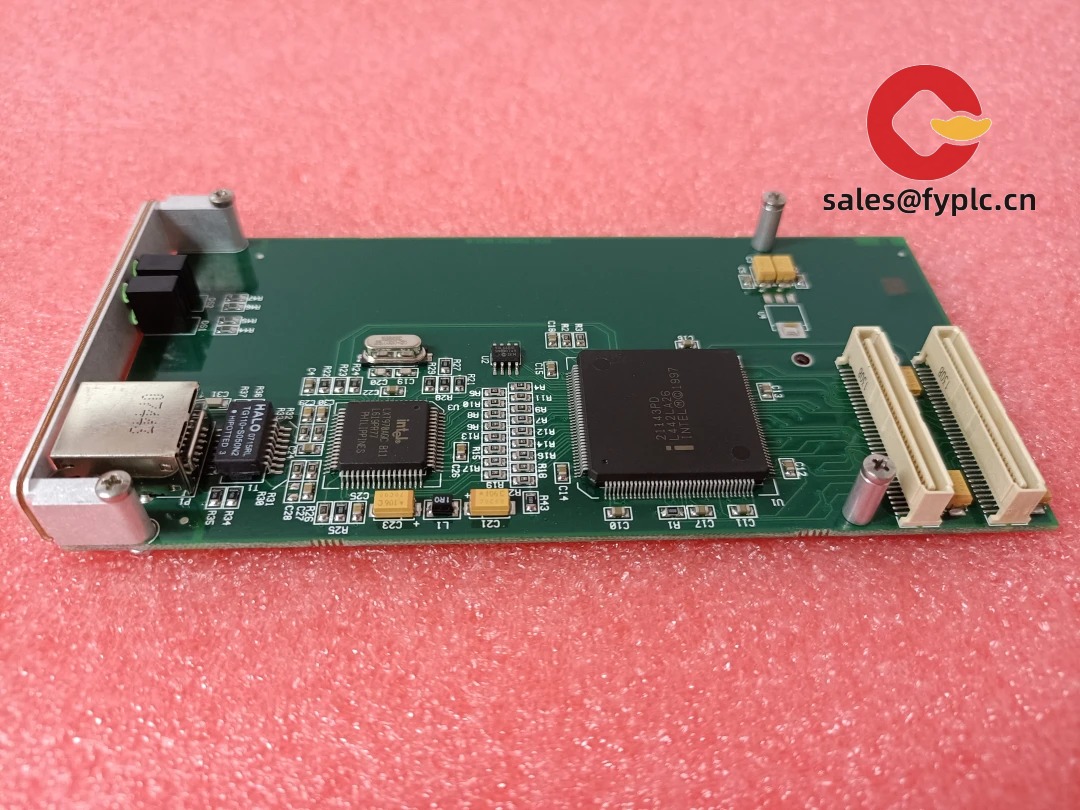

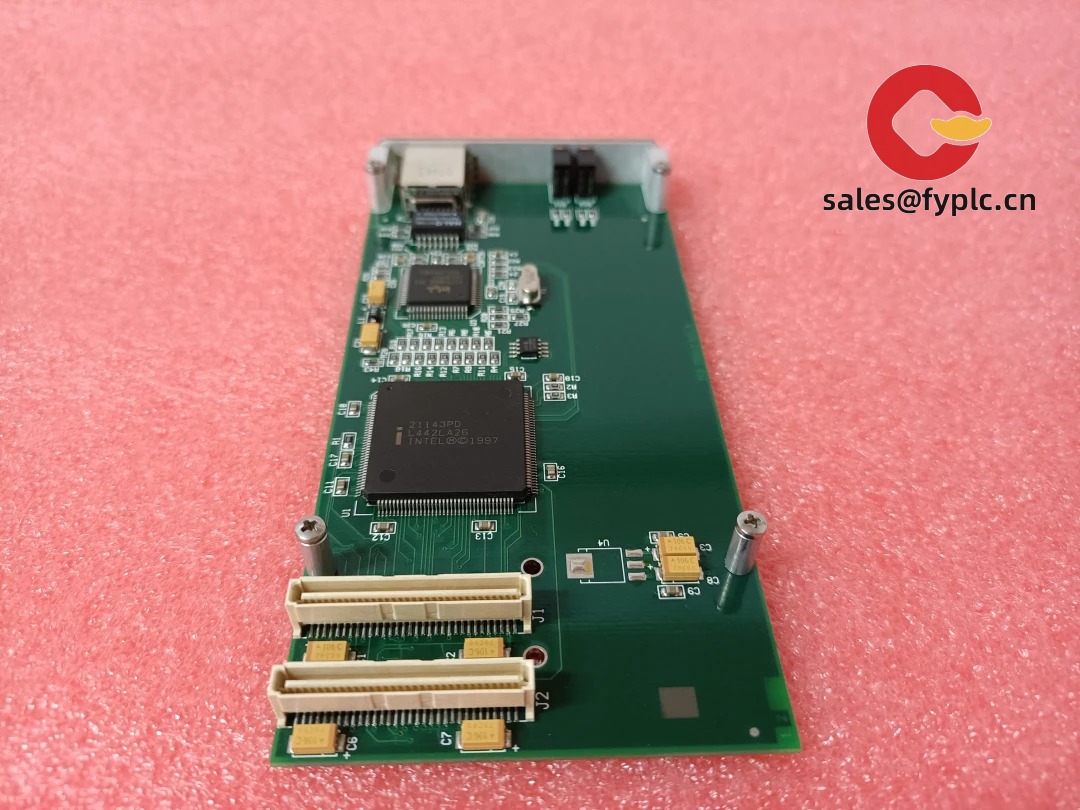

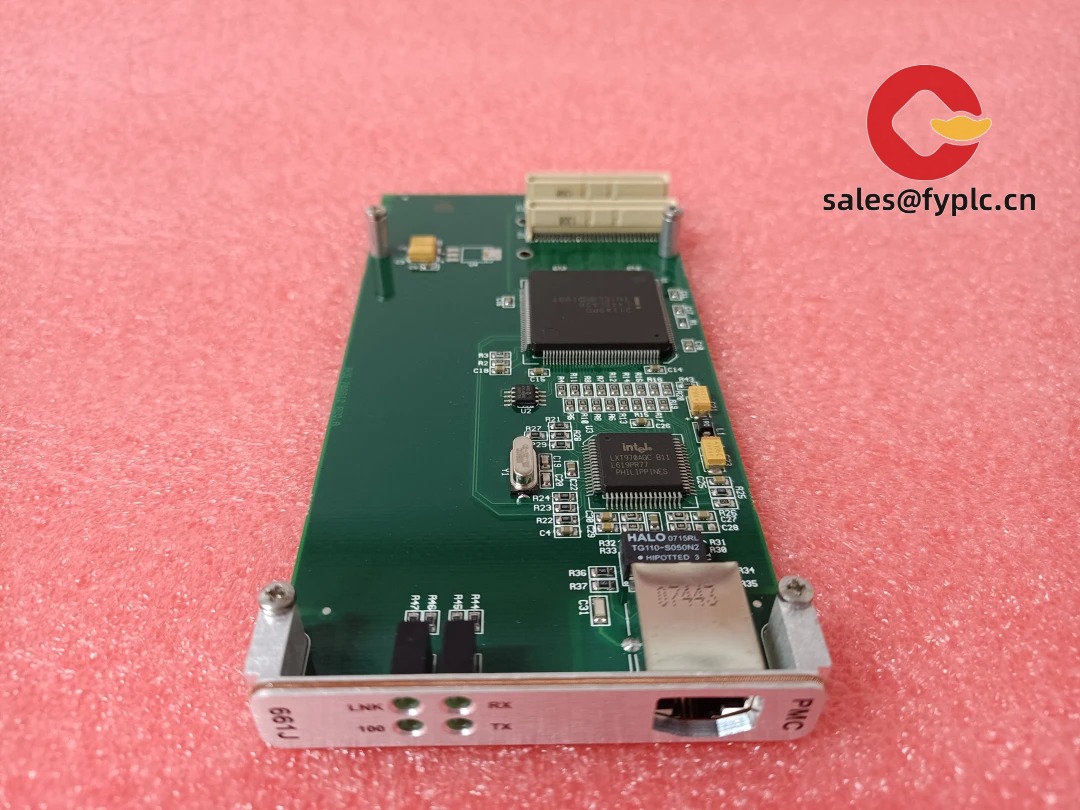

Schneider Electric PowerLogic PMC661J: Real-Time Energy Intelligence for Industrial Power Systems

You know how tricky it is to pinpoint energy waste in aging manufacturing lines? This meter’s been my go-to solution when clients need granular visibility into their power quality issues. From my experience, it catches voltage sags and harmonic distortions that standard meters miss – one automotive plant in Michigan actually traced recurring motor failures to transient spikes this unit detected during shift changes.

Ordering & Guarantees

When you order this unit, you’ll get a full 365-day warranty from shipment date. For in-stock items, we typically ship within a week – and never more than a month for special orders. Payment’s straightforward: 50% upfront to secure your order, the rest when it’s ready to ship. We use FedEx, UPS, or DHL to get it to you fast, and honestly? Most customers tell us the delivery timing beats their internal procurement paperwork.

Key Features

- Class 0.5S accuracy – Measures down to 0.1% error even with dirty power, which matters when you’re verifying utility bills for a 5MW facility

- Modbus TCP + RTU dual comms – Seems to be the sweet spot for plants running both legacy SCADA and new IIoT platforms without gateway headaches

- 10-channel waveform capture – One thing I appreciate is how it timestamps transients during production runs, so you’re not guessing if that voltage dip caused the line stoppage

- Web-based configuration – Typically cuts setup time by half compared to menu-driven meters, though you’ll still want basic networking knowledge

Technical Specifications

| Specification | Details |

|---|---|

| Brand/Model | Schneider Electric PowerLogic PMC661J |

| HS Code | 9028.20.0000 (Electrical energy meters) |

| Power Requirements | 85-265V AC, 50/60Hz ±10% (wide-range input handles unstable grids) |

| Dimensions & Weight | 96x96mm panel cutout, 120mm depth, 0.48kg – fits standard switchgear compartments |

| Operating Temperature | -10°C to +55°C (tested in foundry environments with ambient heat) |

| Signal I/O Types | 4x CT inputs (1A/5A), 3x voltage inputs (600V max), 2x relay outputs, pulse output |

| Communication Interfaces | Dual-port Ethernet (Modbus TCP), RS-485 (Modbus RTU), USB configuration port |

| Installation Method | 96x96mm panel mount with snap-in rails – no special tools needed |

Where It Shines

In food processing plants, I’ve seen it prevent $200k+ in spoilage by catching voltage imbalances during compressor startups. For data centers, it’s become essential for PUE tracking – one client in Singapore used its harmonic analysis to justify replacing aging UPS systems before capacitor banks failed. You might notice that in older facilities with legacy machinery, it pays for itself through demand charge avoidance alone. It’s not just a meter; it’s your first line of defense against unplanned downtime.

Why Procurement Teams Choose This

From a purchasing perspective, the real value shows up in three places: First, the 0.5S accuracy means you won’t get disputed utility bills – one textile mill recovered $18k in overcharges their old meter missed. Second, the dual communication ports avoid costly gateway add-ons when integrating with existing systems. And third? Schneider’s global support network typically gets firmware patches out within 48 hours of vulnerability reports, which matters when you’re managing OT security for multiple sites. It’s not the cheapest meter out there, but the TCO over five years usually beats budget alternatives.

Installation & Maintenance

Mount it in standard 42U cabinets with at least 50mm clearance on sides – that airflow matters when ambient temps hit 45°C. One caveat: always use shielded twisted-pair for CT wiring in high-noise areas like welding stations, otherwise you’ll get phantom current readings. For maintenance, I’d recommend quarterly terminal torque checks (4.5 Nm max) and an annual firmware update during planned shutdowns. The self-diagnostics catch 90% of issues, but you should still verify calibration every 24 months – most calibration labs can handle it in under an hour.

Quality & Certifications

Carries CE, UL 61010-1, IEC 62053-22, and RoHS compliance – critical for global deployments. The 365-day warranty covers parts and labor, though in practice most industrial users report field lifespans exceeding 10 years. One plant manager recently told me they’re still using first-gen units from 2015 with only routine CT replacements. Not bad for hardware monitoring 24/7 in a steel mill environment.

Reviews

There are no reviews yet.