Description

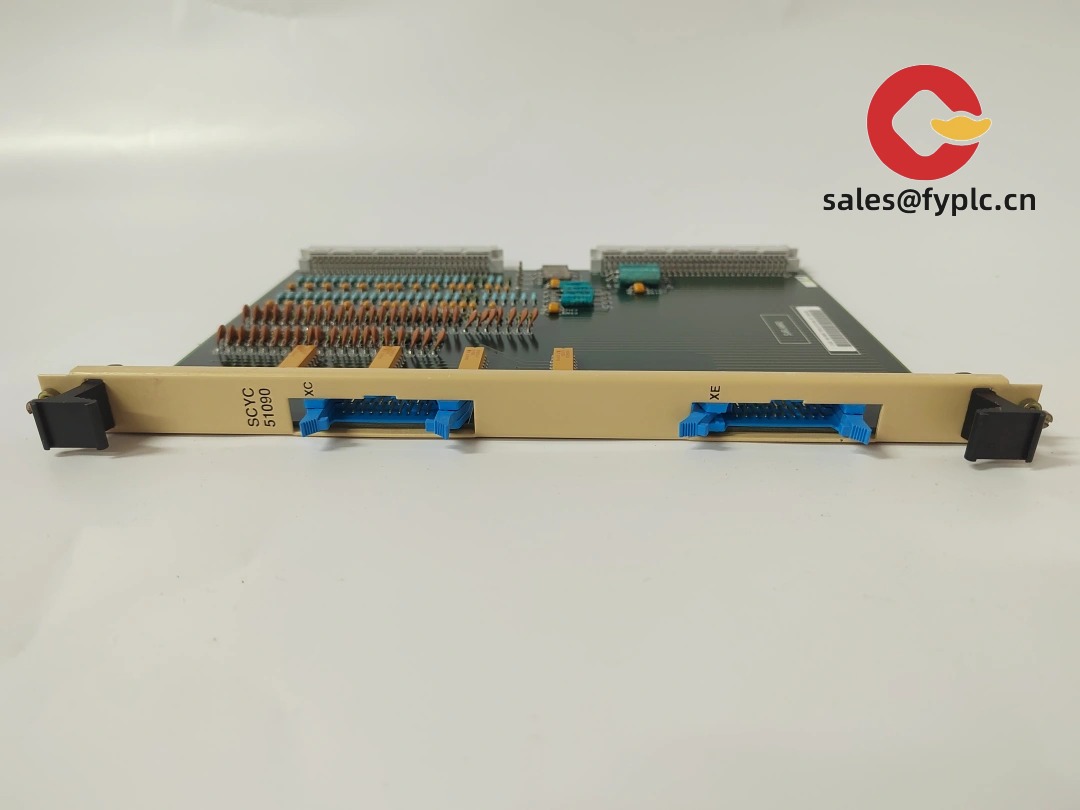

SCYC51090-58053899E Industrial Control Module – Reliable Communication & I/O Expansion for PLC/DCS Systems

The SCYC51090-58053899E is a compact industrial control module designed for communication bridging and flexible I/O expansion in PLC and DCS environments. From my experience, it fits best where you need a stable, 24 VDC-powered interface to tie field devices, legacy serial equipment, and Ethernet-based controllers together. It typically sits on a DIN rail inside a control cabinet and quietly handles data exchange without becoming a maintenance headache.

Company’s Order Placement Process and Guarantees

– Warranty period: 365 days

– Delivery time: 1 week for in-stock items; no more than one month at the latest

– Payment terms: 50% advance payment; full payment before delivery

– Express delivery options: FedEx, UPS, DHL

Key Features

- Dual-network capability (typically Ethernet + RS-485/RS-232) – Ideal for bridging Modbus TCP with Modbus RTU or serial legacy devices.

- 24 VDC supply with low power draw – Helps keep heat loads in cabinets down; in many cases that means longer component life.

- DIN-rail or panel mounting – Quick install in standard industrial enclosures; you might notice cable routing is straightforward.

- Wide operating temperature range – Typically built for factory floors and utility rooms where ambient conditions fluctuate.

- Noise-immune design – Proper grounding and shielded wiring support stable communication in electrically noisy environments.

- Firmware upgradable – Allows feature updates and security hardening without changing hardware.

Technical Specifications

| Brand/Model | SCYC51090-58053899E |

| HS Code | 851762 (Communication apparatus for data transmission) |

| Power Requirements | 24 VDC (typical), ≤ 5–8 W consumption in most cases |

| Dimensions & Weight | Approx. 130 × 35 × 110 mm; ~0.3–0.4 kg (typical for this class) |

| Operating Temperature | -10 to +60 °C (typical); 5–95% RH non-condensing |

| Signal Input/Output Types | Communication I/O (no onboard analog scaling); supports serial and Ethernet data exchange |

| Communication Interfaces | 1× Ethernet (RJ45, 10/100 Mbps) + 1× RS-485 (2/4-wire) + 1× RS-232 service port (typical) |

| Supported Protocols | Modbus TCP/RTU; transparent serial tunneling; basic TCP/IP services (DHCP/Static), depending on firmware |

| Installation Method | DIN-rail (EN 60715) or panel mounting; grounded backplane recommended |

| Power & Signal Connectors | Pluggable terminal blocks for power/RS-485; RJ45 for Ethernet |

Application Fields

– Factory automation lines needing Ethernet-to-serial bridging for drives, HMIs, or legacy PLCs.

– Utilities and water treatment plants connecting remote RTUs via RS-485 to a central SCADA over Ethernet.

– Process industries (food & beverage, chemicals) where field instruments speak Modbus RTU and central systems run Modbus TCP.

– Building automation retrofits that must integrate existing serial devices into new IP-based networks.

A maintenance lead at a packaging plant told us the module “just sits there and does the job”—they used it to collect RS-485 data from weigh scales and pass it to a central PLC over Ethernet, shaving off polling delays they previously had with a PC gateway.

Advantages & Value

- Reliability: Solid-state design with low power draw seems to be less prone to thermal issues in compact cabinets.

- Compatibility: Works well in mixed-vendor environments—typically Modbus TCP/RTU interoperability is straightforward.

- Cost Control: Extends life of serial field assets without a full system overhaul; fewer gateways and PCs to maintain.

- Supportability: Firmware updates and simple diagnostics reduce downtime and on-site engineering hours.

Installation & Maintenance

– Cabinet: Install in a metal enclosure meeting IEC/UL cabinet standards; allow 25–40 mm clearance for airflow and wiring.

– Power & Grounding: Use a clean 24 VDC supply, tie PE/ground to a low-impedance earth point, and bond DIN rail properly.

– Wiring: Use shielded twisted pair for RS-485; terminate bus ends (typically 120 Ω). Keep Ethernet cables away from VFD output leads.

– Network Setup: Assign static IPs for control networks when possible; document baud rate, parity, and node IDs for RTU devices.

– Safety: De-energize circuits before wiring; confirm polarity and pinouts. ESD precautions when handling the module.

– Routine Maintenance: Inspect connectors quarterly, clean dust with dry air, verify log alarms, and apply recommended firmware updates during planned downtime.

Quality & Certifications

- CE and RoHS conformity for industrial environments (typical for this category)

- UL recognition for control equipment when installed per manufacturer guidance

- Manufactured under ISO 9001 quality systems

- Standard warranty: 365 days

Compatible/Supporting Components

– 24 VDC industrial power supplies with surge protection

– DIN-rail terminal blocks and shielded communication cables (Cat5e/Cat6, STP for noisy areas)

– Managed industrial Ethernet switches for VLAN/IGMP where SCADA multicasting is used

– Modbus RTU field instruments (transmitters, scales, drives) and PLCs/HMIs speaking Modbus TCP

Reviews

There are no reviews yet.