Description

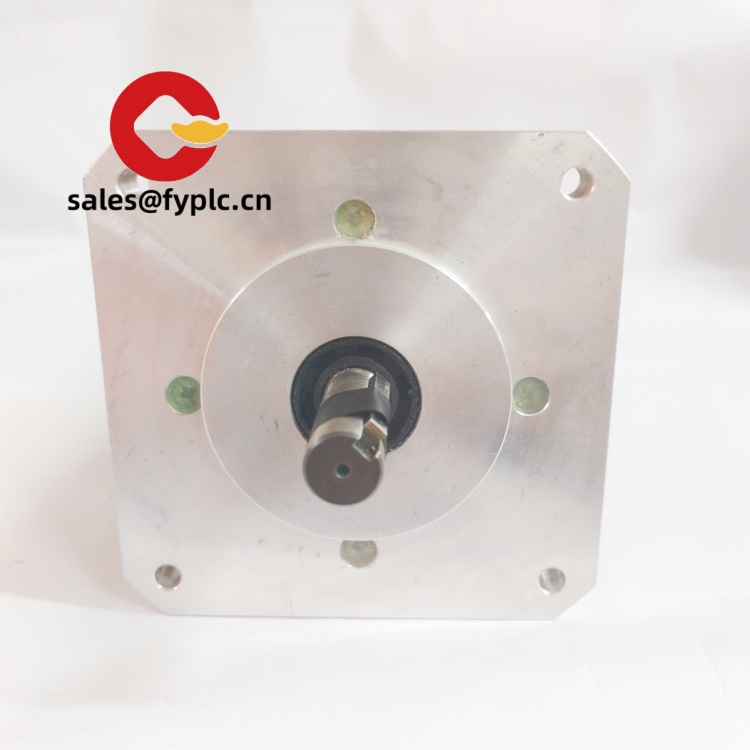

SERVO DYNAMICS MTS30M4-38B Servo Drive – 4‑Quadrant Amplifier for Precision Motion Control

The SERVO DYNAMICS MTS30M4-38B is a robust servo amplifier module designed for demanding industrial motion systems. From my experience, units in the MTS30 family are typically chosen when you need stable torque/velocity control, analog command capability, and dependable protection features without the overhead of a fieldbus drive. You might notice that this model is often used as a drop-in in legacy machines or retrofit projects where consistent, predictable behavior matters more than chasing the latest protocol.

Company’s Order Placement Process and Guarantees

- Warranty: 365 days

- Delivery: 1 week if in stock; no more than one month at the latest

- Payment: 50% advance payment, full payment prior to delivery

- Express options: FedEx, UPS, DHL

Key Features

- 4‑quadrant operation – Regenerative braking and bidirectional control for fast starts/stops and reversals.

- Analog command interface – ±10 V velocity/torque command is common on this series, making it easy to pair with CNCs and PLC motion cards.

- Multiple feedback options – Variants in the MTS30 line support encoder or resolver feedback; the -38B option is typically aligned with brushless setups.

- Industrial protections – Over‑current, over‑temperature, and bus fault handling to safeguard the drive and motor.

- Retrofit‑friendly form factor – Panel/rack mounting with straightforward terminal access helps keep wiring clean in control cabinets.

- Stable tuning – In many cases, simple gain and compensation adjustments deliver crisp response without instability.

Technical Specifications

| Brand / Model | SERVO DYNAMICS MTS30M4-38B |

| HS Code | 850440 (Static converters / servo drive) |

| Power Requirements | Typically 120/240 VAC, 50/60 Hz, single‑phase (confirm against unit nameplate) |

| Operating Temperature | 0 to 40 °C typical control cabinet environment |

| Signal I/O Types | ±10 V analog command; digital enable/fault; encoder or resolver feedback depending variant |

| Communication Interfaces | Analog interface; no integrated fieldbus on most MTS30 units |

| Installation Method | Panel/rack mount inside an industrial control cabinet |

Application Fields

You’ll typically find the MTS30M4-38B in packaging lines, printing and converting machines, material handling gantries, winding/unwinding systems, and machine tool retrofits where a clean ±10 V command scheme is preferred. One thing I appreciate is how easily it drops into existing analog motion loops driven by PLC motion cards or CNC controllers, especially when the goal is to stabilize torque or velocity on a brushless servomotor.

Advantages & Value

- Reliability – Proven analog control architecture; in many cases, less sensitive to electrical noise than low‑cost digital drives.

- Compatibility – Works well with standard ±10 V motion controllers, common encoder/resolver feedback, and industrial motors.

- Cost Savings – Ideal for keeping existing machinery productive without a full control system replacement.

- Supportable – Straightforward wiring and tuning; spare parts and repair services are easier to source for this series.

Installation & Maintenance

- Control cabinet – Mount vertically in a ventilated cabinet (IP54 or better in dusty/humid areas). Allow clearance for heatsinking and airflow.

- Wiring – Use properly shielded motor and feedback cables; bond shields at the drive end; ensure a solid protective earth.

- Power quality – In most cases a line reactor and proper fusing/circuit breaker sizing improve EMC and protect upstream power.

- Tuning – Start with conservative gains; verify current limit and acceleration settings with a no‑load test before production.

- Routine checks – Quarterly dust cleaning, terminal tightening, fan/airflow inspection, and verifying fault logs if available.

- Firmware/Options – These units are largely analog; configuration is hardware/jumper based. Keep a record of jumper positions and any trim‑pot settings.

- Safety – Implement an e‑stop that safely removes the drive’s enable signal and input power according to your machine’s risk assessment.

Quality & Certifications

- Typically compliant with CE for industrial environments; many units are UL Recognized depending on production batch.

- RoHS alignment varies by manufacturing year; we can screen inventory upon request.

- Seller warranty: 365 days. Manufacturer program may vary by vintage; we stand behind testing and functional verification before shipment.

Related Accessories & Supporting Components

- EMC line filter and line reactor (for improved power quality and reduced harmonics)

- External braking resistor (when frequent decel/regen is expected)

- Shielded encoder/resolver cables and connectors matched to the MTS30 terminal set

- Panel cooling fan kit and cabinet thermal monitoring

- Proper fuses/circuit breakers and a main disconnect with lockout capability

Quick customer feedback from a recent retrofit: “Swapped in the MTS30M4‑38B to keep our ±10 V motion loop. Tuning took under an hour, regen handled the load ramps well, and we avoided re‑writing the PLC code.” That seems to be the typical experience when replacing older analog drives in established production cells.

Reviews

There are no reviews yet.