Description

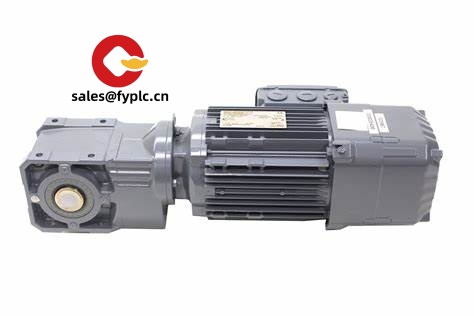

SEW‑EURODRIVE DRN80M4BE1TF – IE3 Brake Motor for dependable conveyor, packaging, and general machine drives

The DRN80M4BE1TF is part of SEW‑EURODRIVE’s DRN series of IE3-efficiency three‑phase AC motors. In practical terms, it’s a compact 4‑pole IEC motor with an integrated spring‑applied DC brake (BE1) and PTC thermal protection (TF). You typically see this model paired with gear units on conveyors, small hoists, indexing stations, or packaging axes where you need fast, repeatable stops and reliable thermal monitoring. From my experience, it’s a solid “install-and-run” option when you want efficiency and low maintenance without complicating the panel.

Company’s Order Placement Process and Guarantees

- Warranty: 365 days

- Lead time: 1 week if in stock; no more than 1 month at the latest

- Payment: 50% advance payment, full payment before delivery

- Express delivery: FedEx, UPS, DHL

Key Features

- IE3 energy efficiency – Reduces power consumption and heat, which in many cases lowers cabinet cooling needs.

- 4‑pole design – Approx. 1500 rpm at 50 Hz (1800 rpm at 60 Hz) for general‑purpose machinery and conveyors.

- Integrated BE1 brake – Spring‑applied DC brake for quick, reliable stopping and position holding on sloped conveyors or light lifting axes.

- PTC thermal sensor (TF) – Early warning of overheating; simple to wire into most drives or safety relays.

- TEFC, IP55 – Totally enclosed fan‑cooled enclosure for dusty shop floors; typically fine for indoor industrial environments.

- IEC footprint (frame 80M) – Easy drop‑in for existing B3 foot‑mounted setups; B5/B14 flange versions are commonly available.

- Wide supply compatibility – Standard 3‑phase 50/60 Hz voltages; works well on VFDs with proper brake control.

Technical Specifications

| Brand / Model | SEW‑EURODRIVE DRN80M4BE1TF |

| Motor Type | Three‑phase asynchronous AC motor, IE3, 4‑pole, with spring‑applied DC brake (BE1) and PTC thermal sensor (TF) |

| Rated Output | Typically 0.75 kW (frame 80M, 4‑pole) |

| Poles / Nominal Speed | 4‑pole; ~1500 rpm @ 50 Hz / ~1800 rpm @ 60 Hz (synchronous) |

| Power Requirements | 3‑phase 230/400 V (Δ/Y) 50 Hz; 277/480 V (Y) 60 Hz |

| Efficiency Class | IE3 per IEC 60034‑30‑1 |

| Insulation / Enclosure / Cooling | Class F insulation (typ. B rise), IP55, TEFC (IC411) |

| Brake System | BE1 spring‑applied DC brake (use with suitable rectifier/brake control) |

| Thermal Protection | PTC thermistor (TF) embedded in winding |

| Signal I/O Types | Power terminals (U/V/W), brake coil leads (DC via rectifier), PTC sensor leads |

| Communication Interfaces | None (encoder options available if positioning/feedback is needed) |

| Installation Method | Foot‑mounted IM B3 (B5/B14 flanges commonly available) |

| Dimensions & Weight | IEC frame 80M (center height 80 mm); typical mass ~9–13 kg depending on options |

| Operating Temperature | −20 °C to +40 °C (standard ambient; higher ambients may require de‑rating) |

| HS Code | 8501.51 (AC motors, multi‑phase, output not exceeding 750 W) |

Application Fields

You might notice this model used on conveyor lines (inclined sections where a holding brake matters), case packers and sealers, small hoists and lifts, indexing turntables, light presses, and mixing/pumping skids. It also pairs cleanly with SEW gear units for compact gearmotors in intralogistics and OEM machinery.

Advantages & Value

- Reliability – Proven DRN platform; the BE1 brake is straightforward to service and holds position consistently.

- Compatibility – Standard IEC frame and terminals make retrofits simpler, typically with no baseplate changes.

- Energy savings – IE3 efficiency helps cut operating costs over the motor’s life, especially in continuous S1 duty.

- Control flexibility – Works well on DOL or VFD; the PTC and brake wiring simplify safe stopping schemes.

- Service & parts – Common spares like rectifiers, fans, and brakes are easy to source, minimizing downtime.

Installation & Maintenance

- Mounting – Install on a rigid, flat base (IM B3). Align shaft carefully; use flexible couplings to limit bearing load.

- Ventilation – Keep rear fan guard unobstructed; provide cabinet/area ventilation for ambient ≤40 °C.

- Wiring – Use appropriately sized shielded motor cable when driven by VFD. Route brake and PTC leads separately from power where possible.

- Brake control – Use a proper DC brake rectifier or dedicated brake chopper from the drive; verify release voltage and response time.

- Routine checks – Inspect fan, terminals, and brake air gap periodically; clean dust build‑up. Bearings are typically grease‑for‑life in this size.

- Thermal monitoring – Integrate the PTC into your drive/controller. Trip at manufacturer‑recommended thresholds to avoid insulation stress.

- Firmware & VFD – If used with a VFD, keep firmware current and enable motor nameplate parameters for best efficiency and torque control.

Quality & Certifications

- Conformity: CE; designed to IEC 60034 series; RoHS compliant components

- Protection/Insulation: IP55, Class F (typical), suitable for S1 continuous duty

- Manufacturer warranty: 12 months (365 days)

Optional Accessories & Compatible Components

- Brake rectifier modules for BE1 (panel‑mount or drive‑integrated types)

- Incremental/absolute encoders for closed‑loop control and positioning

- SEW gear units (R/F/K/S series) to form compact gearmotor assemblies

- Motor thermal relay or safety module accepting PTC inputs

Reviews

There are no reviews yet.