Description

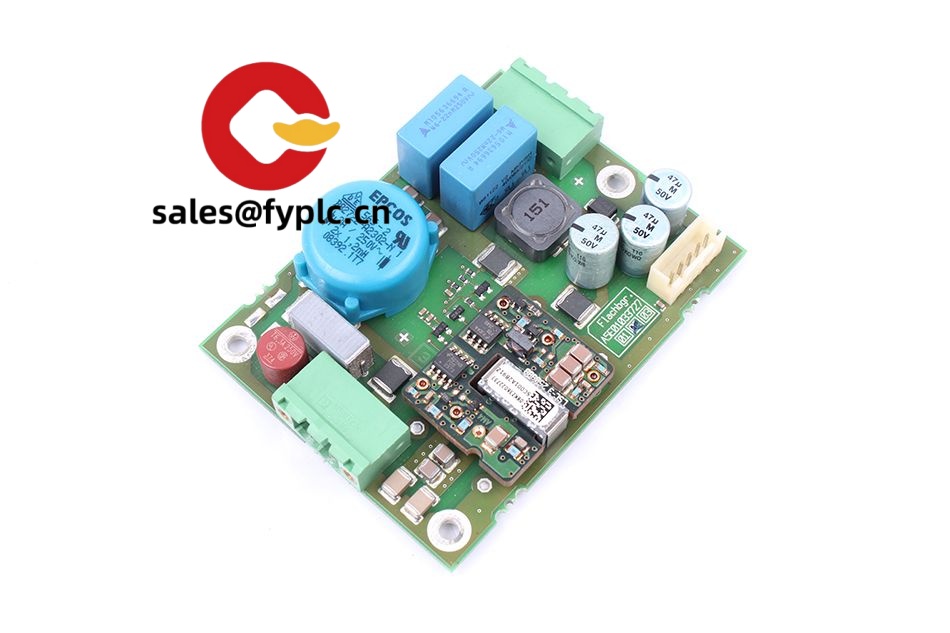

Siemens 6SL3120-2TE21-8AA3 – SINAMICS S120 Double Motor Module for compact multi‑axis servo control

The Siemens 6SL3120-2TE21-8AA3 is a SINAMICS S120 booksize Double Motor Module designed for two-axis control on a common DC bus. From my experience, this is the go-to format when you want high dynamic performance and clean cabinet layouts without stacking separate drives. It pairs with a CU320‑2 or CU310 control unit via DRIVE‑CLiQ, and typically runs both synchronous and induction servomotors with tight speed/position control. You might notice that the double-axis design often saves cabinet space and wiring time compared with two single modules.

Company’s Order Placement Process and Guarantees

- Warranty: 365 days

- Delivery time: 1 week for in-stock; no more than one month at the latest

- Payment: 50% advance payment, full payment for delivery

- Express delivery methods: FedEx, UPS, DHL

Key Features

- Double-axis “booksize” module – two motor outputs in one unit for dense cabinets and simplified wiring.

- Common DC bus architecture – energy sharing between axes and easy pairing with SINAMICS Line Modules.

- DRIVE‑CLiQ integration – plug-and-play topology with CU320‑2/CU310 and Siemens sensor/terminal modules.

- High dynamic servo control – suitable for synchronous and induction motors in fast indexing or contouring tasks.

- 24 V DC control supply – keeps the control electronics alive for diagnostics even when the DC link is off.

- Safety-ready hardware – Safe Torque Off via terminals is available on many S120 Motor Modules; this unit follows that platform concept (verification by exact option set is recommended).

- Service-friendly – front-access terminals, clear status LEDs, and quick module replacement reduce downtime.

- System tools – commissioning via STARTER or TIA Portal Startdrive, with trace and diagnostics that save hours on-site.

Technical Specifications

| Brand / Model | Siemens SINAMICS S120 / 6SL3120-2TE21-8AA3 (Double Motor Module, booksize) |

| HS Code | 850440 (Static converters) |

| Power Requirements | Common DC bus from SINAMICS Line Module (approx. 600 V DC nominal); 24 V DC control supply |

| Operating Temperature | Typically 0…+40 °C without derating (higher temps possible with derating as per Siemens guidelines) |

| Signal Input/Output Types | 2× three‑phase motor outputs (U/V/W); DC link terminals; 24 V control; STO terminals on safety‑equipped versions |

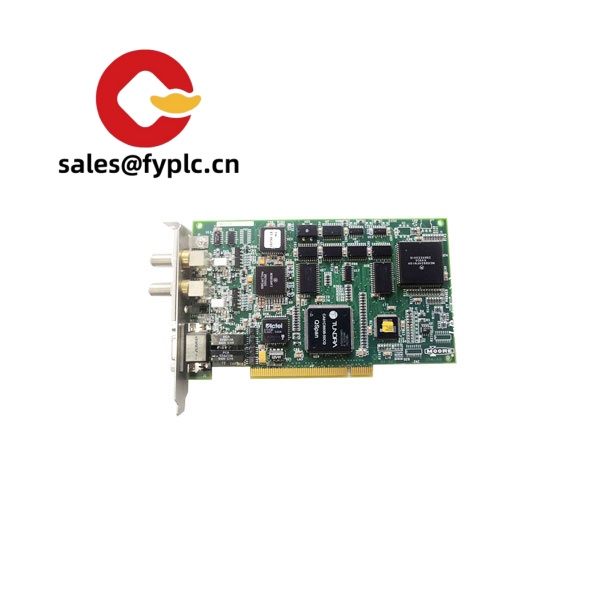

| Communication Interfaces | DRIVE‑CLiQ to CU320‑2 / CU310 and Siemens peripheral modules |

| Installation Method | Panel/cabinet mounting, booksize vertical orientation; integrate on common DC bus with appropriate Line Module and EMC grounding |

Application Fields

This module suits multi-axis machinery where space and response time matter: machine tools, packaging and pick‑and‑place lines, printing and converting, electronics assembly, intralogistics, and small robotics. A packaging OEM told us they swapped two singles for this double module and freed up enough rail space to add an extra axis without resizing the cabinet—simple but impactful.

Advantages & Value

- Cabinet efficiency – two axes in one frame typically cuts footprint and wiring effort.

- Lifecycle and availability – SINAMICS S120 is widely deployed, with solid long‑term parts support.

- Seamless compatibility – native with Siemens control units, sensor/terminal modules, and Drive‑CLiQ accessories.

- Service cost savings – fast swap, consistent parameter structures, and mature diagnostic tools reduce downtime.

- Scalability – straightforward to expand on the common DC bus as machine requirements evolve.

Installation & Maintenance

- Cabinet environment – mount vertically on a grounded backplate; allow top/bottom clearance for airflow; maintain filtered ventilation.

- Power architecture – supply via SINAMICS Line Module on a common DC bus; feed 24 V DC to control electronics (UPS‑backed 24 V is recommended for safe diagnostics and logging).

- Wiring & EMC – use shielded motor and encoder cables; bond shields 360°; keep motor and control wiring separated; follow Siemens grounding and leakage current notes.

- Safety – implement STO wiring per manual if used; verify stop category and risk assessment on site.

- Commissioning – identify modules over DRIVE‑CLiQ, set motor data, autotune, and verify thermal/current limits for both axes.

- Routine care – keep cabinet filters clean; check terminal torque and DC bus connections; back up parameter sets; update firmware through STARTER or TIA Portal Startdrive when appropriate.

Quality & Certifications

- Certifications: CE; typically cULus; RoHS compliant for most S120 booksize variants

- Manufacturer warranty: 12 months (365 days)

- Documentation: Siemens SINAMICS S120 manuals for Motor Modules, DRIVE‑CLiQ topology, safety, and EMC

Commonly Paired Components (for quick, clean builds)

- SINAMICS Line Modules (e.g., 6SL3130‑… for the DC bus)

- Control Units CU320‑2 PN/DP or CU310‑2

- Sensor Modules for encoder feedback (DRIVE‑CLiQ)

- Braking resistors and line reactors (6SL3000‑… series)

- DRIVE‑CLiQ cables and terminal modules for I/O and safety

Reviews

There are no reviews yet.