Description

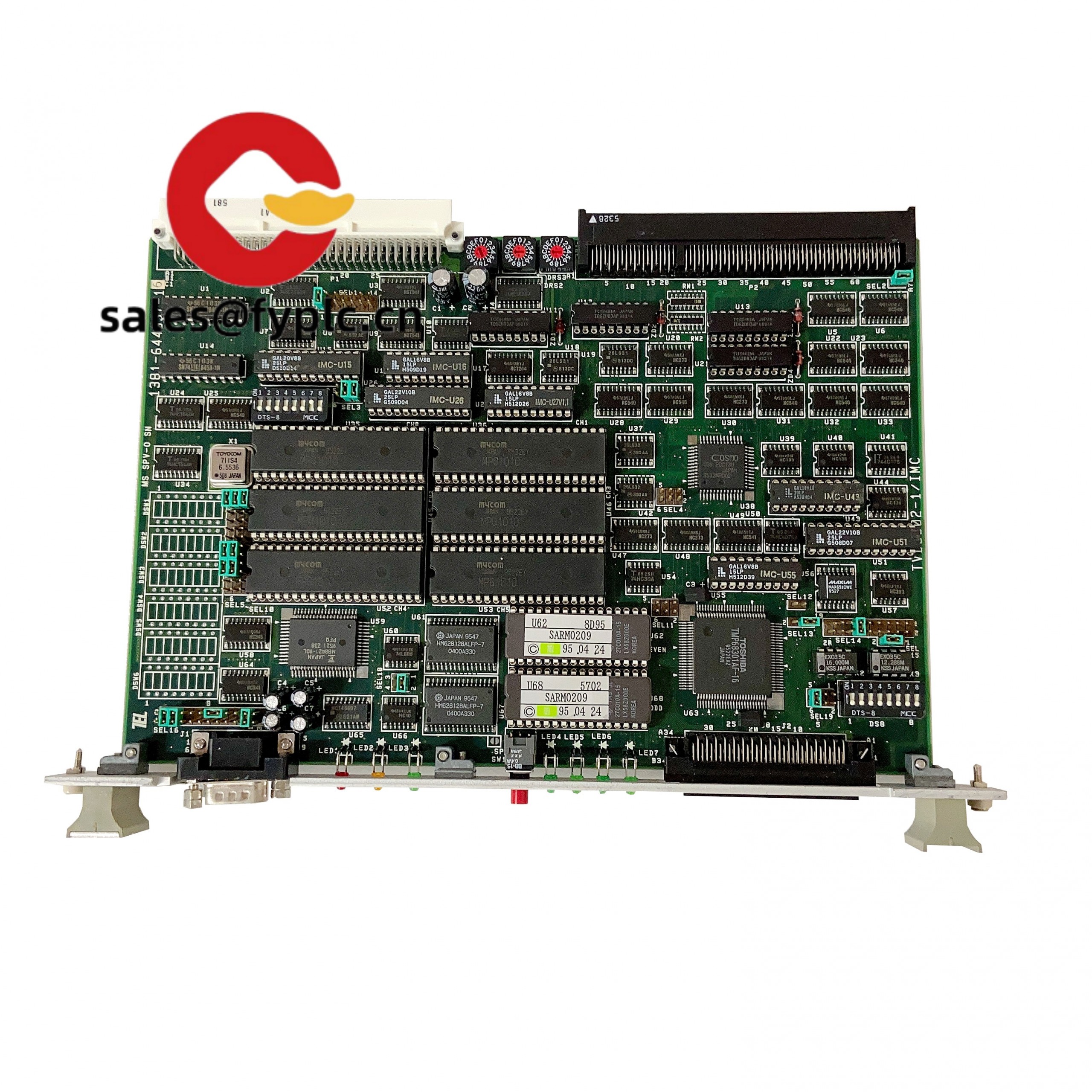

TEL TVB6002-1IMC – I/O Control Interface Board for TEL Semiconductor Tools

The TEL TVB6002-1IMC is a field-replaceable control interface board used on Tokyo Electron (TEL) equipment to marshal tool I/O—typically vacuum valves, sensors, interlocks, and actuator control. From my experience, this board sits in the electronics bay and bridges 24 VDC field signals with the tool’s controller/backplane. You might notice that TEL uses it across several tool families where stable, noise-immune digital I/O and a few analog channels are required.

Company’s Order Placement Process and Guarantees

- Warranty: 365 days

- Lead time: 1 week when in stock; no more than one month at the latest

- Payment: 50% advance payment; full payment before delivery

- Express options: FedEx, UPS, DHL

Key Features

- Designed for TEL tool integration – Works as an I/O interface within TEL electronics bays, aligning with standard 24 VDC plant wiring and TEL backplane conventions.

- 24 VDC digital I/O – Sinks/sources typical tool signals for valves, prox sensors, door/cover interlocks, and pressure switches.

- Mixed-signal support – In many cases provides a small number of analog channels (0–10 V or 4–20 mA) for process feedback or setpoints.

- Diagnostic LEDs – Front-edge indicators that make channel-level checks quick; one thing I appreciate is how faults can be pinpointed without a laptop.

- Noise-robust design – Opto-isolation and filtering on most inputs; helps with EMI in high-power vacuum environments.

- Field-replaceable – Swaps in minutes with standard tools; usually no mechanical rework or re-termination needed.

- Configuration retention – Settings/firmware are typically maintained by the host system, reducing post-replacement setup time.

Technical Specifications

| Brand / Model | TEL TVB6002-1IMC |

| HS Code | 8486.90 (Parts of semiconductor manufacturing equipment) |

| Power Requirements | 24 VDC nominal, < 15 W typical (varies by I/O loading) |

| Dimensions & Weight | Compact board-level module; approximate footprint similar to other TEL I/O boards (thin card form). Weight typically < 0.5 kg. |

| Operating Temperature | 5 to 40 °C, non‑condensing (electronics bay environment) |

| Signal Input/Output Types | 24 VDC digital inputs/outputs (opto-isolated); limited analog I/O (0–10 V and/or 4–20 mA) depending on build revision |

| Communication Interfaces | TEL backplane interface; service access typically via RS‑232C/RS‑485 on relevant tool platforms |

| Installation Method | Mounted inside the tool electronics bay; board/card secured with standoffs or card guides; field wiring via terminal blocks or harness connectors |

Related or Supporting Products

- TEL TVB6002-2IMC – Similar I/O interface board; often used when additional channel density or revised connector keying is required. Check harness compatibility.

- TEL TVB6001 series – Earlier-generation boards with comparable digital I/O; may differ in analog channel availability and LED layout.

- 24 VDC DIN-rail power supply (industrial) – Stable 24 VDC source (5–10 A headroom recommended) for cabinet distribution feeding the I/O board and actuators.

- Shielded I/O harnesses – Pre-terminated cables for sensors/valves; keeping shields grounded at the cabinet side typically reduces EMI issues.

- RS‑232C/RS‑485 service cable – For on-bay diagnostics or configuration when supported by the tool.

Installation & Maintenance

- Cabinet & environment – Install in a clean, ventilated electronics bay per TEL standards. Maintain airflow around the board; avoid heat sources and moisture.

- Wiring – Use 24 VDC-rated wiring with proper ferrules. Separate high-current solenoid lines from low-level analog signals; land shields at a single ground point to minimize loops.

- Grounding & ESD – Bond the cabinet ground; follow ESD precautions when handling the board. From my experience, this prevents intermittent input chatter.

- Commissioning – Verify LED status for each channel, then run the tool’s I/O test. Analog channels (if used) should be checked against a handheld calibrator.

- Routine care – Quarterly: inspect connectors, re-seat harnesses, and blow off dust with dry air. Firmware/config is typically managed by the host; update only per OEM service notes.

- Spare strategy – Keep one qualified spare on hand; many fabs report fastest MTTR when a known-good TVB6002-1IMC is stocked in the bay store.

What customers tell me: “The diagnostic LEDs saved us hours—faulted valve coil was obvious in seconds,” which seems to be a common theme on night shifts.

Quality & Certifications

- Certifications – CE conformity when installed within the TEL system; RoHS compliant builds commonly available. UL/CSA applicability is typically at the cabinet/system level.

- Manufacturing quality – Produced under ISO 9001 quality management at the OEM level.

- Warranty – 365-day warranty from us, covering functional performance under normal use.

- Traceability – Serial/label tracking supports lot-level traceability for audits and tool history.

Reviews

There are no reviews yet.