Description

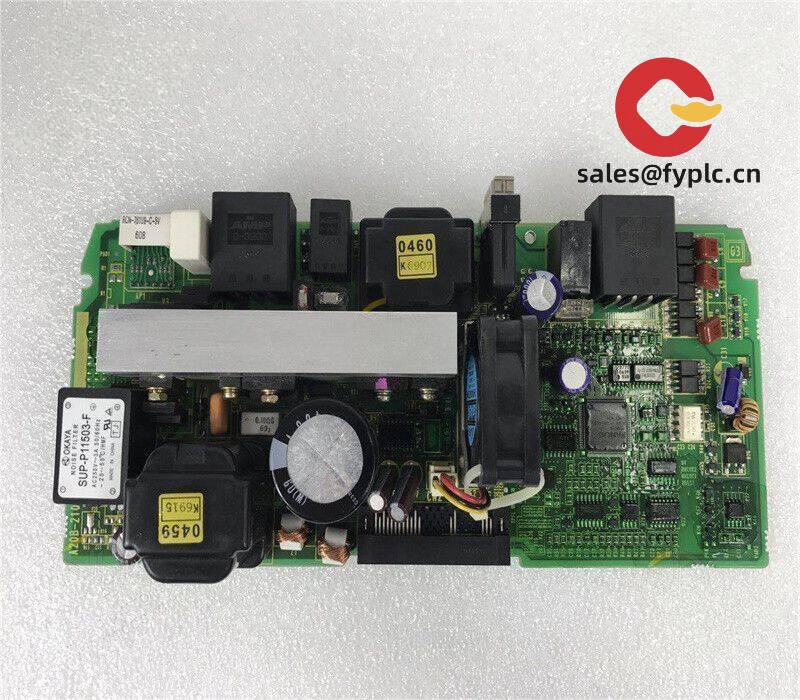

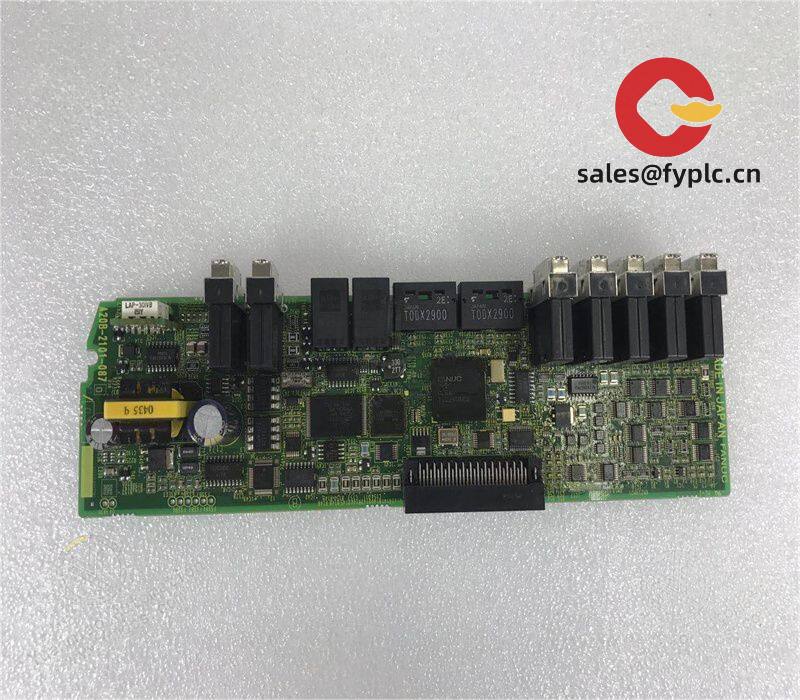

TRICONEX 2101 – Module for Triconex TMR Safety Systems

The TRICONEX 2101 is a Triconex system module designed to operate within the Triconex Triple Modular Redundant (TMR) safety platform. From my experience, it’s typically used as a spare or replacement card to keep legacy and current Tricon installations running with high availability. You might notice that it follows the familiar Tricon design philosophy: triplicated architecture, continuous diagnostics, and hot-swap handling to avoid unnecessary shutdowns. That combination is exactly what plants rely on in ESD, BMS, and critical turbomachinery applications.

Company’s Order Placement Process and Guarantees

- Warranty: 365 days standard coverage

- Delivery: 1 week if in stock; no more than one month at the latest

- Payment terms: 50% advance payment; full payment before delivery

- Express options: FedEx, UPS, DHL

Key Features

- Engineered for Triconex TMR systems – Works within the triplicated backplane environment to support fault tolerance and high SIL applications.

- Backplane-powered and hot-swappable – Designed to be inserted/removed in the designated slot without powering down the entire chassis, reducing downtime.

- On-board diagnostics – Continuous self-checking and system health reporting to help maintenance teams isolate issues quickly.

- Industrial-grade build – Robust construction and, in many cases, conformal coating to handle typical plant conditions and airborne contaminants.

- Lifecycle compatibility – Appears to be compatible with established Tricon chassis and toolsets, easing spares management for brownfield upgrades.

- Documentation support – Traceability and revision management for maintaining compliance dossiers and MOC records.

Technical Specifications

| Brand / Model | TRICONEX 2101 |

| HS Code | 853710 (Control panels/PLCs and similar apparatus) |

| Power Requirements | Supplied via Triconex chassis backplane; typically 5 VDC/24 VDC provided by system power modules |

| Dimensions & Weight | Standard Tricon plug-in card form factor; fits Tricon main chassis. Exact outline available on request. |

| Operating Temperature | Typically 0 to 60 °C ambient within a rated enclosure |

| Signal Input/Output Types | Backplane data and TMR voting signals; field I/O handled by dedicated Triconex I/O modules/termination assemblies |

| Communication Interfaces | Triplicated Triconex system backplane; system diagnostics visible via TriStation software (system-dependent) |

| Installation Method | Hot-swappable, front-insert module; secure with front-panel fasteners in the specified chassis slot |

Application Fields

Plants typically deploy the TRICONEX 2101 within Triconex safety systems for process industries where downtime is costly and safety layers must be independently verified. Typical scenarios include:

- Emergency Shutdown (ESD) and High Integrity Pressure Protection (HIPPS) in oil & gas

- Burner Management Systems (BMS) for boilers, heaters, and furnaces

- Turbomachinery protection and shutdown for gas/steam turbines and compressors

- Chemicals and refining unit interlocks where proof testing and diagnostics matter

- Power generation balance-of-plant safety interlocks

A maintenance lead at a refinery told me they swapped a 2101 during a turnaround, closed the front-panel fasteners, and went through system validation without touching the wider process network—small detail, but it saved them hours.

Advantages & Value

- Reliability – TMR architecture and diagnostics reduce single-point failures and unplanned outages.

- Compatibility – Designed for Triconex chassis and toolsets, simplifying spares stocking across multiple units.

- Lifecycle cost – Drop-in replacement approach often avoids costly rewiring or I/O cabinet changes.

- Support readiness – Documentation, revision traceability, and technical guidance to streamline FAT/SAT and proof testing.

Installation & Maintenance

- Cabinet & environment – Install in a Triconex-rated chassis within a clean, dry, and ventilated enclosure; maintain ambient temperature within the specified range.

- Wiring & grounding – Follow Triconex grounding and shielding practices; field I/O remains on dedicated I/O modules/termination assemblies.

- ESD handling – Use antistatic protection and handle by the front panel; avoid touching edge connectors.

- Firmware/diagnostics – Verify module revision in TriStation, apply approved firmware only, and log proof-test results per site procedures.

- Routine care – Periodically inspect for dust, check front-panel fasteners, and confirm healthy status indicators before/after turnaround events.

Quality & Certifications

- Part of the Triconex safety platform, which is typically TÜV-certified for SIL3 in accordance with IEC 61508/61511 (system-level certification).

- CE and UL compliance are commonly supported for Triconex hardware; specific DoC available on request.

- RoHS/Reach status available by revision; many installed-base spares follow industry exemptions where applicable.

- Warranty: 365 days from shipment.

If you’d like, share your installed Triconex system revision and slot plan—I can help confirm 2101 compatibility and lead time before you place the order.

Reviews

There are no reviews yet.