Description

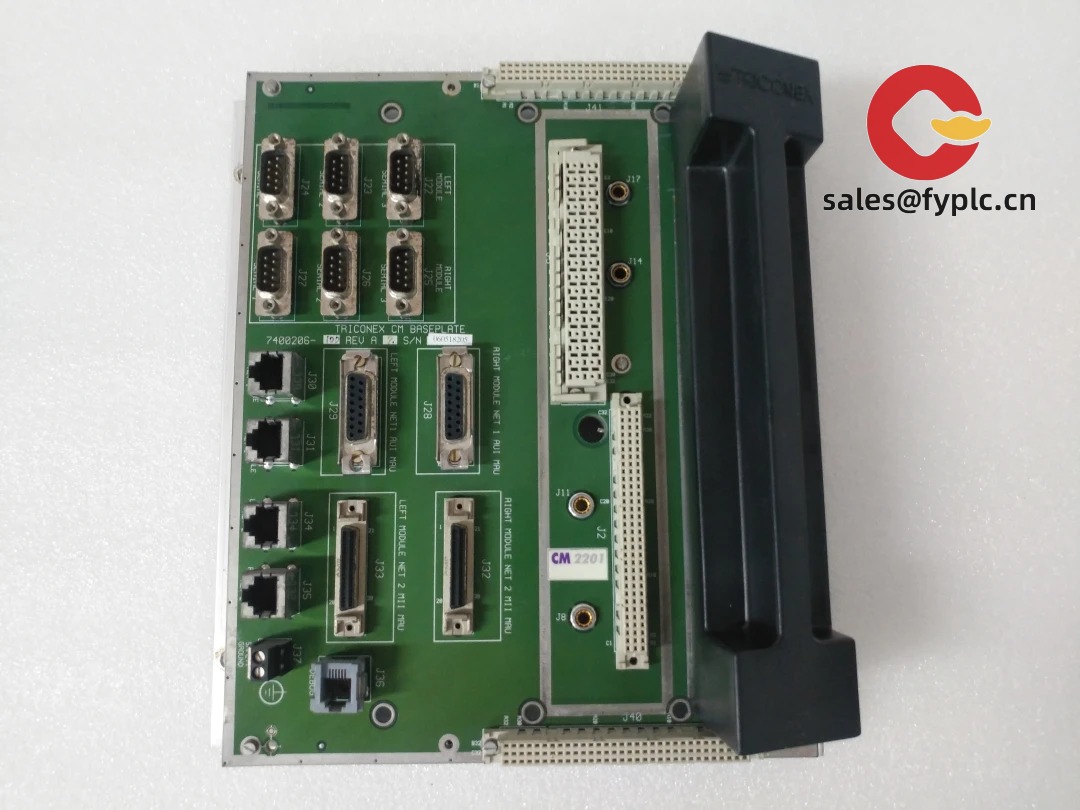

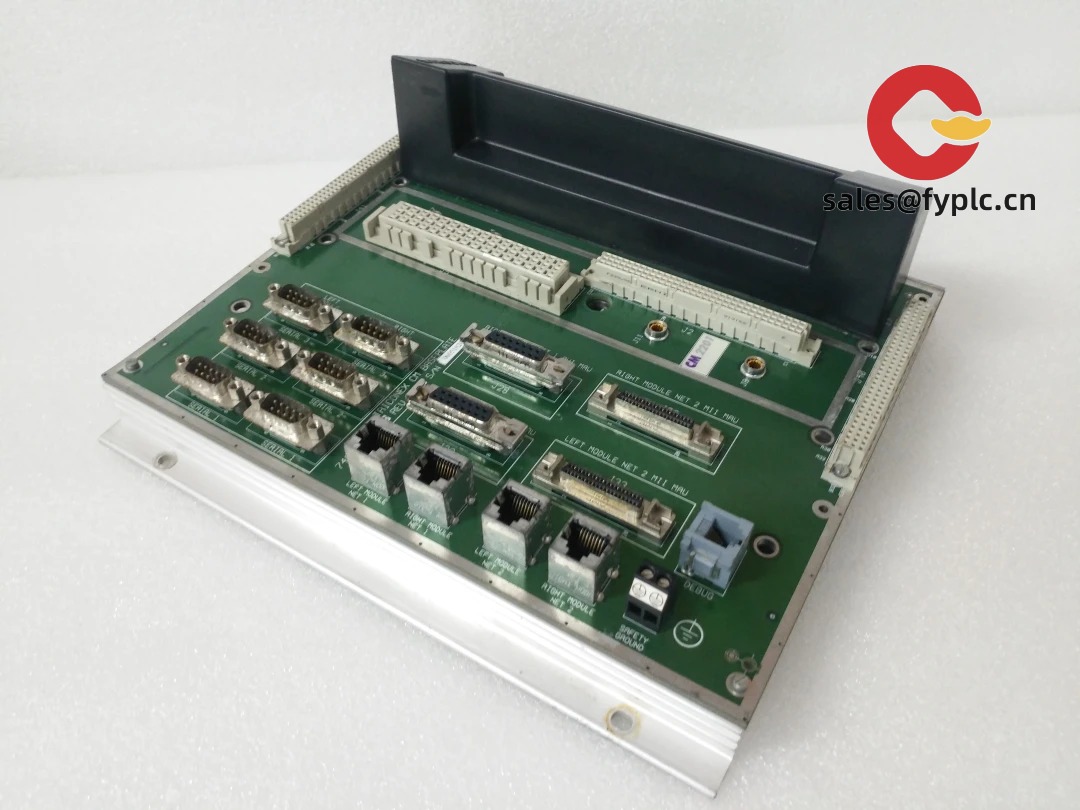

Triconex 2201 — High-Integrity Trip Logic Solver for Safety-Critical Shutdown Systems

Triconex 2201 isn’t just another logic solver—it’s the workhorse behind many of the world’s most demanding safety instrumented systems (SIS), especially where SIL 3 compliance and true fault tolerance matter. From offshore platforms shutting down gas compressors during overpressure events, to chemical plants preventing runaway reactions, this module handles trip decisions with triple-modular redundancy (TMR) baked right into its architecture. One thing I appreciate is how quietly it operates: no fans, no moving parts, and—unlike some newer controllers—it doesn’t demand constant firmware babysitting to stay certified.

Key Features

- TMR Architecture: Three independent processor channels vote on every output—so if one channel fails or drifts, the system continues operating without interruption. In practice, this means fewer unplanned shutdowns during maintenance windows.

- Built-in Diagnostic Coverage: Monitors internal memory, power rails, and communication paths continuously. You might notice that diagnostic alarms appear early—often before a fault impacts process availability.

- Hot-Swappable Design: Replace modules under power without disturbing adjacent racks. A refinery client in Texas told us they cut average replacement time from 45 minutes to under 90 seconds—just by swapping the 2201 while the unit stayed online.

- IEC 61508 & IEC 61511 Certified: Validated up to SIL 3 for both hardware and software. Certification documentation is included with shipment—not buried behind NDAs or portal logins.

- Legacy-Compatible Backplane: Fits directly into Triconex 3000-series cabinets (e.g., TRICON, TriStation 1131 environments). No adapter kits needed—even if your engineering station runs Windows XP-era configuration tools.

Technical Specifications

| Parameter | Specification |

|---|---|

| Brand / Model | Triconex 2201 |

| HS Code | 8537.10.90 (Industrial programmable controllers) |

| Power Requirements | 24 VDC ±10%, 1.2 A typical (backplane-powered) |

| Dimensions & Weight | 170 mm H × 45 mm W × 230 mm D; ~0.95 kg |

| Operating Temperature | 0 °C to 60 °C (derated above 45 °C) |

| Signal Input/Output Types | Digital inputs (24 VDC sink/source), digital outputs (relay or solid-state) |

| Communication Interfaces | TriBus (proprietary TMR backplane bus), optional Modbus RTU via 2210 expansion module |

| Installation Method | DIN-rail mounted in Triconex 3000-series chassis (e.g., 3511, 3521) |

Application Fields

This module shows up where failure isn’t an option—offshore oil & gas platforms managing emergency shutdown (ESD) systems, petrochemical crackers relying on burner management safety systems (BMSS), and pharmaceutical cleanroom HVAC interlocks requiring SIL 3 validation. It’s also common in older nuclear auxiliary systems, where regulatory acceptance of legacy TMR logic remains strong. From my experience, it’s rarely chosen for greenfield DCS-integrated SIS deployments—but it’s still the go-to when replacing failed 2000-series modules in brownfield sites with tight certification timelines.

Advantages & Value

If you’re sourcing replacements for aging Triconex infrastructure, the 2201 delivers predictable value: full backward compatibility means no requalification effort for existing SIL verification reports. Spare part lead times are typically shorter than for newer models—especially outside North America—because the design has been stable since ~2007. And unlike some vendors who bundle support into annual subscriptions, Triconex technical assistance for the 2201 remains accessible without paywalls. That said, firmware updates are infrequent (last major release was v4.1.2 in 2021), so don’t expect IoT-style feature drops—just rock-solid, auditable behavior.

Installation & Maintenance

Install only in NEMA 12 or IP54-rated cabinets with minimum 100 mm clearance above/below for convection cooling. Avoid mounting near VFDs or high-current bus ducts—the 2201’s analog input rejection isn’t as robust as newer designs. Wiring must follow ISA-50.00.01 grounding practices: separate instrument and safety ground conductors, bonded at a single point. For maintenance: calibrate input modules annually using TriStation 1131’s built-in test routines; wipe heatsinks with dry lint-free cloth every 18 months; and verify TriBus checksums quarterly (they’ll flag if backplane noise exceeds thresholds). Firmware updates aren’t mandatory for SIL 3 operation—but we recommend applying v4.1.2 if you haven’t yet, as it patches a rare watchdog timeout edge case observed in high-vibration environments.

Quality & Certifications

Certified to IEC 61508 Ed. 2 (SIL 3), IEC 61511-1:2016, UL 61010-1, CE (EMC & LVD), and RoHS 2011/65/EU. Not UL 1604 or ATEX-certified—so avoid Zone 1 installations unless housed in purged enclosures. The manufacturer’s warranty is 365 days from date of shipment. We stand behind that: if a unit fails calibration out-of-box or shows latent manufacturing defects, we’ll replace it—no paperwork marathons, no “return authorization” delays.

Our Order Placement Process & Guarantees:

• Warranty: 365 days

• Delivery: 1 week for in-stock units; ≤30 days maximum, even for configured spares

• Payment: 50% advance, balance before dispatch

• Shipping: FedEx, UPS, or DHL—fully insured, with real-time tracking

• Note: Lead times assume standard configuration (no custom firmware builds or special labeling)

Reviews

There are no reviews yet.