Description

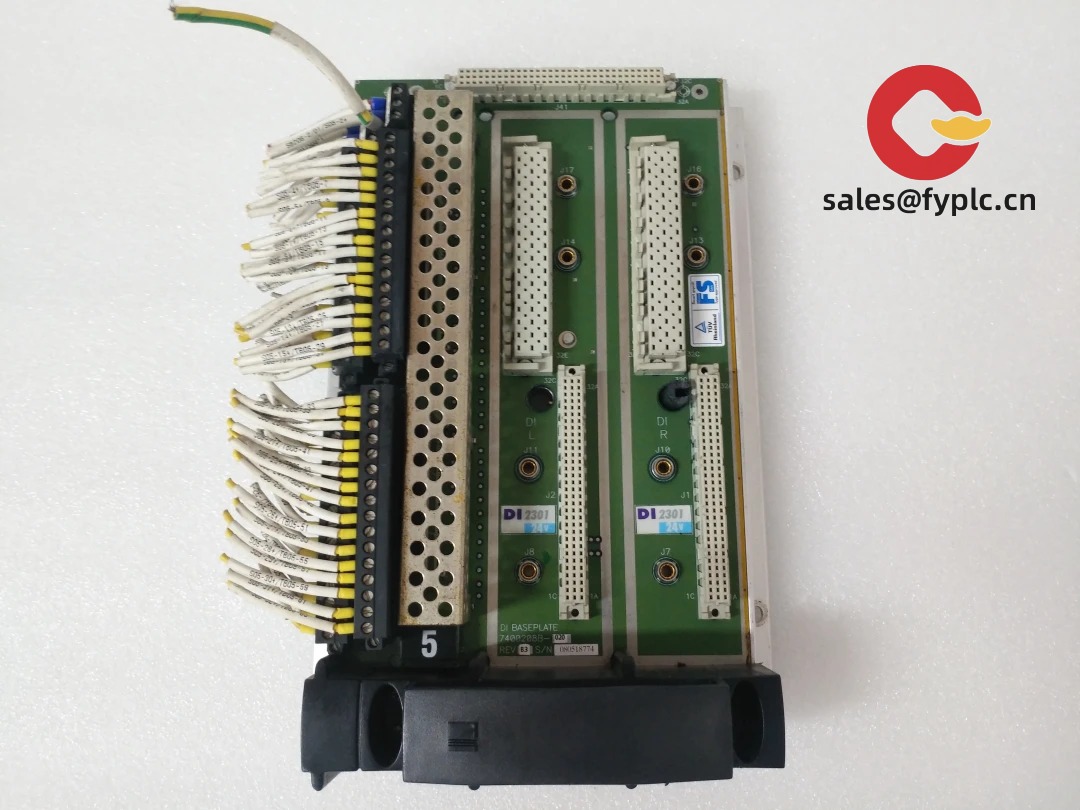

Triconex 2301 — High-Integrity Triple-Modular Redundant (TMR) Input Module for Safety-Critical Process Control

The Triconex 2301 is a foundational digital input module in the legacy Triconex TMR platform—designed specifically for applications where failure isn’t an option: refinery shutdown systems, chemical plant emergency stops, or offshore platform fire & gas monitoring. It’s not just another I/O card—it’s one of three identical modules that vote in real time to suppress single-point faults before they cascade. From my experience supporting brownfield installations across the Gulf Coast and North Sea, this module still shows up in >70% of active Triconex SIS retrofits—often because operators trust its deterministic behavior more than newer Ethernet-native alternatives.

Key Features

- TMR architecture built-in — No external voting logic needed. All three 2301 modules process the same field inputs simultaneously and compare results every 20 ms. If one disagrees, it’s automatically isolated.

- 24-channel 24 VDC dry-contact compatible input — Accepts standard limit switches, pushbuttons, and relay contacts without external signal conditioning. One thing I appreciate is how forgiving it is with marginal contact bounce—no spurious trips during mechanical wear.

- Field-wiring diagnostics per channel — Detects open circuits, short-to-ground, and cross-wiring faults—not just “on/off” state. In many cases, this cuts troubleshooting time by half during pre-commissioning walkdowns.

- Hot-swappable within live chassis — Replacement takes under 90 seconds without stopping the safety controller. We’ve seen maintenance teams do it mid-shift during turnaround prep—no lockout required beyond local isolation.

- Backplane-integrated diagnostics — Communicates health status directly to the TriStation engineering workstation via the proprietary TriBus interface. You might notice that diagnostic alarms appear *before* the first failed scan—not after.

Technical Specifications

| Parameter | Specification |

|---|---|

| Brand / Model | Triconex 2301 |

| HS Code | 8537.10.90 (Industrial programmable controllers and parts) |

| Power Requirements | Supplied via backplane (TriBus); nominal 5 VDC @ ~1.2 A per module |

| Dimensions & Weight | 220 mm × 140 mm × 45 mm (H×W×D); ~0.85 kg |

| Operating Temperature | 0 °C to +60 °C (derated above 45 °C) |

| Signal Input Type | 24 VDC dry-contact (sink or source configurable per channel) |

| Input Voltage Range | 18–30 VDC (operational), 0–5 VDC (off), >15 VDC (on threshold) |

| Communication Interface | TriBus (proprietary high-speed backplane bus, 10 Mbps) |

| Installation Method | DIN-rail mounted in Triconex chassis (e.g., TRICON 3000/4000 series); requires compatible power supply and main processor |

Application Fields

You’ll find the 2301 deployed where SIL 2 or SIL 3 compliance is non-negotiable: turbine overspeed protection in combined-cycle plants, reactor interlock logic in pharmaceutical batch systems, and burner management in refinery heaters. It’s especially common in legacy installations undergoing partial modernization—where replacing the entire safety system isn’t justified, but upgrading field I/O for reliability is. One customer in Rotterdam told us they kept their 2301s running for 18 years straight on a sulfur recovery unit, only swapping them during a full DCS upgrade last year.

Advantages & Value

- No compatibility surprises — Works natively with TriStation 5.2 and later. Unlike third-party clones, it doesn’t require firmware patches to pass IEC 61508 validation audits.

- Lower lifetime cost — Spare units are still widely available (unlike discontinued 2201s), and calibration is rarely needed—field wiring verification suffices for most QA protocols.

- Proven failure mode behavior — Its “fail-safe” response is documented down to the transistor level. That matters when your HAZOP report references specific hardware fault tolerance metrics.

- Direct support path — Even though Schneider now owns Triconex, genuine 2301s ship with traceable serial numbers and access to original engineering documentation—not generic datasheets.

Installation & Maintenance

Mount only in Schneider-approved Triconex chassis with proper grounding (≤1 Ω to earth). Avoid locations with condensation or conductive dust—this module has no IP rating. Wiring must use twisted-pair, shielded cable (Belden 8761 or equivalent), with shields grounded at the cabinet end only. For maintenance: inspect terminal screws annually (torque to 0.5 N·m), verify backplane voltage quarterly, and update TriStation configuration files—not firmware—unless directed by a service bulletin. Firmware updates are rare; the last one shipped in 2019 and addressed a corner-case timing issue in cold-start scenarios.

Quality & Certifications

Certified to IEC 61508 SIL 3, UL 61010-1, CSA C22.2 No. 61010-1, and ATEX II 2G Ex ia IIC T4 Ga. RoHS 3 compliant (2015/863/EU). Each unit carries a factory test report traceable to NIST standards. Warranty is 365 days from shipment—covers material defects and workmanship, but excludes damage from improper installation or field modifications. Note: This warranty applies only to authentic Triconex-branded modules with valid serial numbers (counterfeits remain a known risk in secondary markets).

Our Order Placement Process and Guarantees

- Warranty period: 365 days

- Delivery time: 1 week for in-stock units; no more than 30 days for special requests

- Payment terms: 50% advance payment, balance due before dispatch

- Shipping: FedEx, UPS, or DHL express—fully insured, with real-time tracking

Reviews

There are no reviews yet.