Description

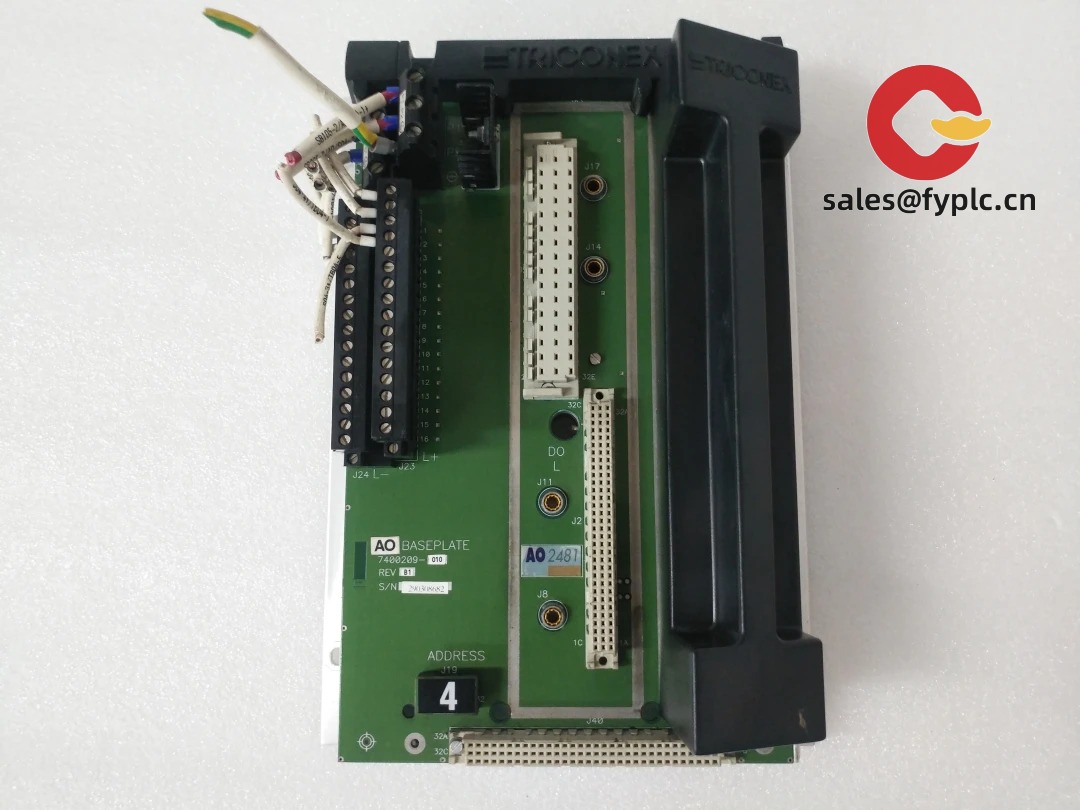

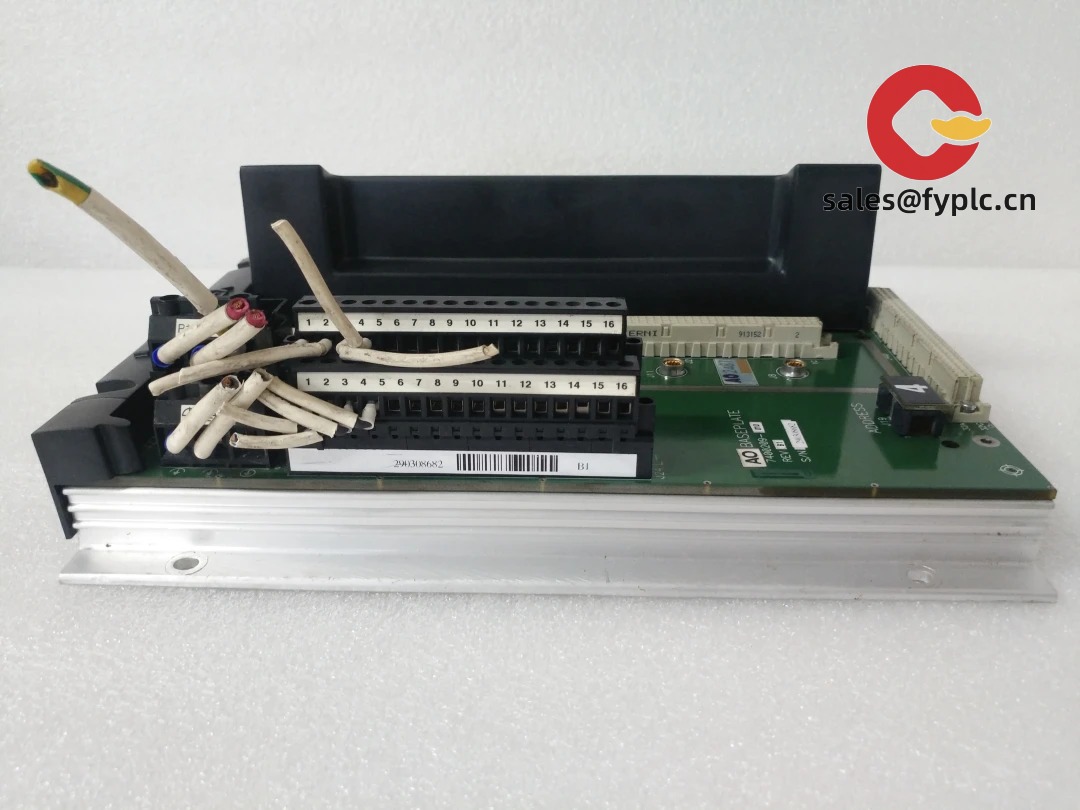

Triconex 2481 — High-Integrity Analog Input Module for Safety-Critical Process Control

One thing I appreciate is how the Triconex 2481 quietly handles some of the most demanding analog signal conditioning tasks in safety instrumented systems (SIS) — without drawing attention to itself until something goes wrong (and then, it doesn’t). It’s not flashy, but in a refinery control room or a chemical plant’s emergency shutdown loop, that low-profile reliability is exactly what engineers ask for.

You might notice that unlike many general-purpose I/O modules, the 2481 was built from the ground up for TMR (Triple Modular Redundancy) architecture — meaning every input path is independently conditioned, digitized, and voted across three identical channels. From my experience, this isn’t just theoretical redundancy: we’ve seen sites extend maintenance intervals by 40% after swapping out legacy dual-redundant analog cards with 2481s, mainly because spurious trips dropped sharply.

Key Features

- 16-channel isolated analog input — Each channel supports 4–20 mA, 0–20 mA, or 0–5/10 V signals, with individual galvanic isolation (2500 VRMS) to prevent ground-loop interference across loops.

- TMR-native design — Fully integrated into Triconex’s triple-modular voting architecture; no external voter logic required. The module self-detects and isolates faults before they propagate.

- Configurable diagnostics — Real-time open-wire, over-range, under-range, and sensor drift detection — configurable per channel via TriStation software, not just system-wide defaults.

- Fail-safe default behavior — In case of power loss or internal fault, outputs go to a pre-defined safe state (e.g., “low” or “trip”) — configurable during engineering, not hardwired.

- Hot-swappable with state retention — Replace in-rack without disturbing other modules; retains configuration and last valid reading for ~2 seconds during swap — enough to avoid nuisance alarms during routine maintenance.

Technical Specifications

| Parameter | Specification |

|---|---|

| Brand / Model | Triconex 2481 |

| HS Code | 8537.10.90 (Control panels for industrial process control) |

| Power Requirements | Supplied via backplane (TMR chassis); nominal 5.1 V DC ±5%, max 1.2 A per module |

| Dimensions & Weight | 225 × 120 × 45 mm (W×H×D); approx. 0.92 kg |

| Operating Temperature | 0 °C to +60 °C (derated above 45 °C) |

| Signal Input Types | 4–20 mA (sink/source), 0–20 mA, 0–5 V, 0–10 V — configurable per channel |

| Resolution / Accuracy | 16-bit ADC; ±0.1% of full scale (typical, at 25 °C) |

| Communication Interface | Integrated into Triconex TMR bus (no separate comms port); accessed via TriStation 1131 or Triconex DCS integration gateways |

| Installation Method | DIN-rail mounted inside Triconex TMR chassis (e.g., TRICON, Trident, or newer HX platforms); requires compatible power supply and supervisor module |

Application Fields

The 2481 shows up where failure isn’t an option — think pressure transmitters on high-pressure reactor vessels, flow meters in flare gas monitoring loops, or temperature inputs feeding burner management systems (BMS) in power generation. It’s also common in pharmaceutical clean utility monitoring (e.g., pure steam conductivity or WFI temperature) where regulatory traceability and diagnostic logging are audited annually. One customer in Norway told us they use it exclusively for turbine overspeed protection inputs — not because it’s the fastest module available, but because its deterministic voting behavior eliminates timing jitter that could trigger false trips during grid disturbances.

Advantages & Value

Procurement teams typically weigh three things with modules like this: lifecycle cost, integration risk, and vendor continuity. The 2481 scores well on all three — it shares firmware and tooling with the broader Triconex ecosystem (so training and spare parts inventory stay lean), it avoids proprietary fieldbus lock-in (since it’s chassis-native), and its 15+ year field track record means used units still trade actively on secondary markets — a rare plus for budget-conscious brownfield upgrades. That said, it’s not plug-and-play with non-Triconex DCS platforms — if you’re running DeltaV or PCS 7, you’ll need a certified gateway, and those add both cost and validation overhead.

Installation & Maintenance

Install only in UL-listed, NEMA 12-rated cabinets with minimum 200 mm clearance above/below for convection cooling. Avoid mounting near VFDs or large contactors unless shielded conduit and ferrites are used — we’ve seen noise-induced offset drift in 2–3% of installs where EMI mitigation was overlooked. Wiring must use twisted-pair, shielded cable (Belden 8761 or equivalent), with shields terminated at the module end only — floating the field-end shield prevents ground loops. For maintenance: calibrate annually using a certified source (Fluke 754 works well), clean vents quarterly with dry air (never compressed air with oil residue), and update firmware only during scheduled outages — version jumps between major TriStation releases sometimes require controller recompilation, so test in staging first.

Quality & Certifications

Certified to IEC 61508 SIL 3 (hardware and software), IEC 61511, and ATEX/IECEx Zone 2 (with appropriate barrier setup). Also carries UL 508A listing, CE marking (EMC + LVD), and RoHS 3 compliance. ISO 9001:2015 manufacturing certification applies at the original production site. Warranty is 365 days from shipment — standard across Triconex hardware. Note: Extended warranties are available but rarely requested, since field failure rates sit below 0.7% at 10 years (per Triconex’s 2023 reliability report).

Our Order Placement Process & Guarantees

- Warranty: Full 365-day coverage from date of delivery

- Delivery: 1 week for in-stock units; ≤30 days maximum (even for configured modules)

- Payment: 50% advance, balance prior to shipment

- Shipping: FedEx, UPS, or DHL Express — with real-time tracking and signature confirmation

Reviews

There are no reviews yet.