Description

TRICONEX 3008 Main Processor – TMR core for Tricon safety and critical control

The TRICONEX 3008 is the main processor (MP) module at the heart of the Tricon safety instrumented system. It runs the triple-modular-redundant (TMR) logic, coordinates all I/O modules through the backplane, and keeps the plant running safely even when single faults happen. From my experience, this is the module that gives engineering teams confidence to do online maintenance and still sleep at night.

Company’s Order Placement Process and Guarantees

- Warranty: 365 days

- Delivery: 1 week if in stock; no more than one month at the latest

- Payment: 50% advance payment; full payment before delivery

- Express options: FedEx, UPS, DHL

Key Features

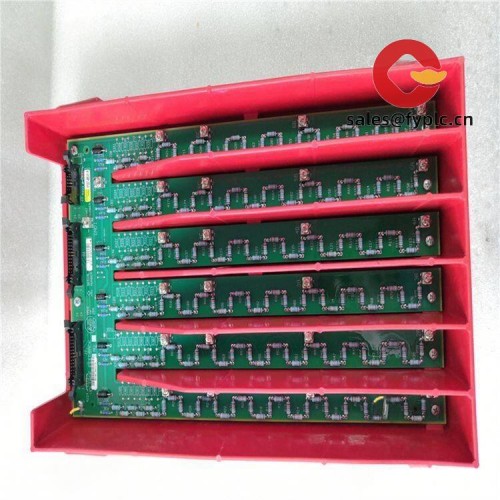

- TMR architecture with 2oo3 voting – Three independent processing paths continuously vote results, so a single fault typically won’t impact plant operation.

- Extensive online diagnostics – Continuous self-test and module-level health reporting reduce troubleshooting time and help plan maintenance windows.

- Hot-replacement capability – In many cases, modules can be replaced online under the TMR protection strategy when procedures are followed.

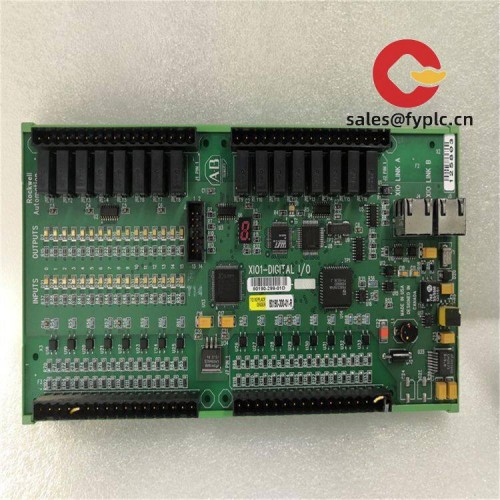

- Secure backplane communication – Coordinates with Tricon I/O and communication modules; no direct field wiring on the MP itself, which simplifies lifecycle management.

- Designed for high SIL applications – Widely used in SIS applications such as ESD, BMS, HIPPS, and turbomachinery protection where SIL3 is required.

- Stable revision control – Mature platform that tends to integrate smoothly with existing Tricon racks and TriStation 1131 engineering workflows.

Technical Specifications

| Brand / Model | TRICONEX 3008 (Main Processor Module for Tricon system) |

| HS Code | 8537.10 (Programmable controllers) |

| Power Requirements | Powered via Tricon backplane; no external power input on the module |

| Dimensions & Weight | Standard Tricon 3000‑series plug‑in form factor; fits Tricon chassis slot (module weight varies by revision) |

| Operating Temperature | 0 to 60°C ambient (typical system rating; refer to the manufacturer’s datasheet for the exact limits) |

| Signal Input/Output Types | Backplane data/control only; no direct field I/O on the MP module |

| Communication Interfaces | Internal Tricon backplane; external networks via dedicated communication modules (e.g., TCM/3703E) and TriStation 1131 tools |

| Installation Method | Plug‑in to Tricon chassis; captive fasteners; supports online replacement when approved procedures are followed |

Application Fields

You’ll typically find the 3008 at the center of safety loops where downtime and nuisance trips are costly. Common roles include:

- Emergency Shutdown (ESD) in oil & gas production and refining

- Boiler/Burner Management Systems (BMS) in power and process

- HIPPS and high-integrity shutdowns in midstream and pipelines

- Turbomachinery protection for compressors and turbines

- Process safeguarding in chemicals, petrochemicals, and LNG

- High-availability safety interlocks in pharmaceuticals and specialty manufacturing

Advantages & Value

- Reliability under fault conditions – The TMR approach with continuous voting seems to be the preferred way to limit spurious trips and keep running during single failures.

- Compatibility with installed bases – Fits the established Tricon platform, so migrations are smoother and spares strategies stay simple.

- Lifecycle cost control – Keeping the core processor aligned with your existing modules typically reduces engineering hours compared to a full rip-and-replace.

- Support and knowledge base – A mature ecosystem of field experience, best practices, and tools (TriStation 1131) shortens commissioning and turnaround time.

“We swapped a failing processor online under TMR without a plant trip—took under an hour including validation.” — Maintenance Supervisor, gas processing site

Installation & Maintenance

- Cabinet & environment – Install in a clean, dry, ventilated cabinet with adequate airflow. Keep ambient within specified limits and avoid heat sources.

- Chassis & grounding – Use the correct Tricon chassis and ensure proper protective earth bonding. Maintain clearances around the module for convection.

- Wiring & backplane – The MP connects via the Tricon backplane; field wiring lands on I/O modules only. Inspect backplane connectors for debris or bent pins.

- Hot-replacement – Allowed in most cases under TMR, but follow the vendor procedure: place the slot in maintenance mode, verify firmware compatibility, and confirm diagnostics healthy before and after.

- ESD protection – Use antistatic wrist straps and bags when handling the module. Avoid touching connector contacts.

- Routine care – Periodically review diagnostics, back up logic via TriStation, check event logs, and plan firmware updates in coordination with change management.

Quality & Certifications

- Designed for use in IEC 61508 SIL3 safety instrumented systems (TÜV certification is standard for Tricon systems)

- CE compliance for EMC and safety; UL/CSA registrations typically available for system components

- Manufactured under ISO 9001 quality systems

- RoHS conformity applies to many revisions; verify per part number and region

- Warranty: 365 days from our side

If you’re refreshing a Tricon rack or building spare coverage, the TRICONEX 3008 is usually the first module to lock in. You might notice that keeping processor and I/O revisions aligned reduces commissioning friction and keeps diagnostics predictable.

Reviews

There are no reviews yet.