Description

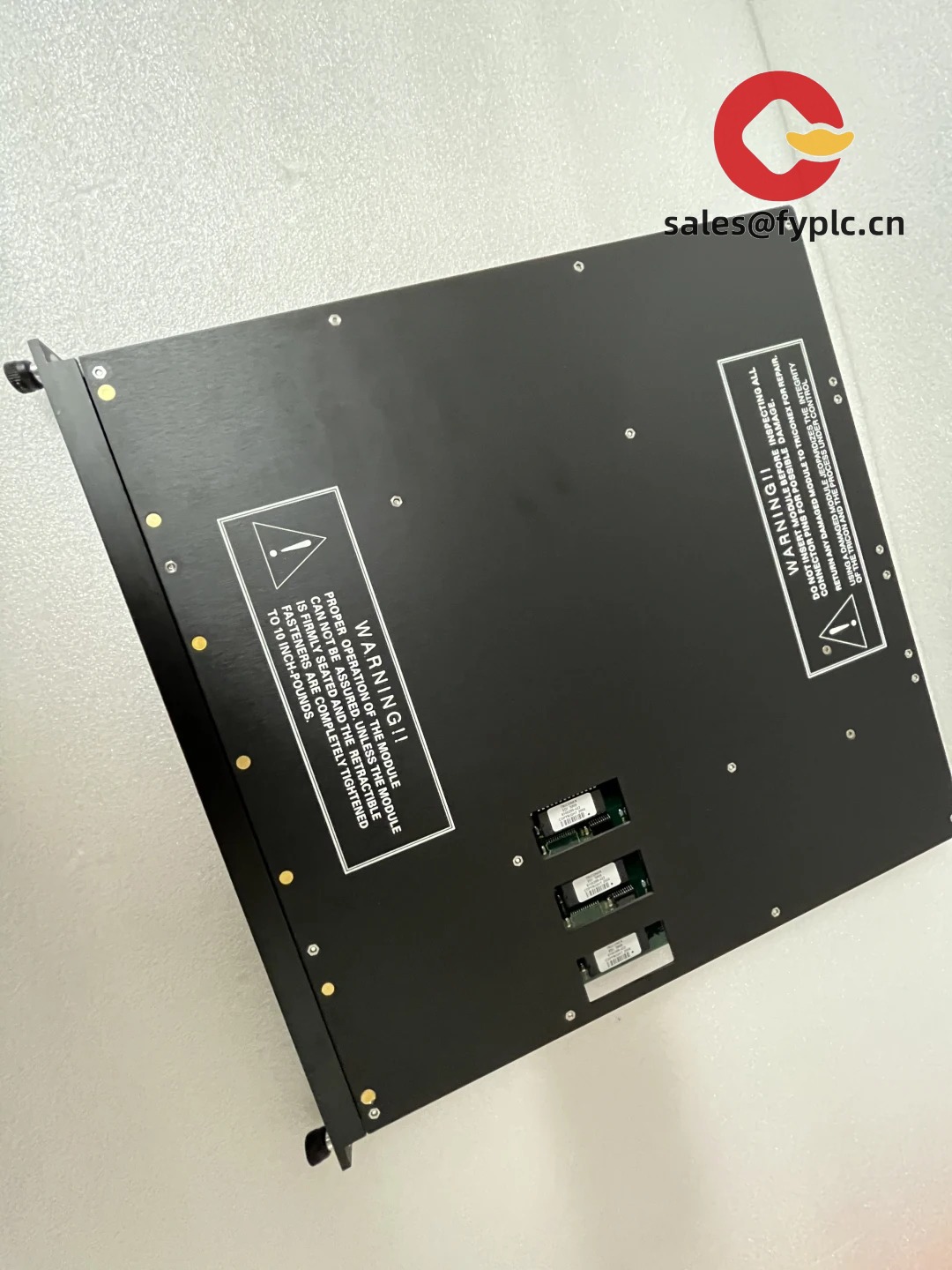

Triconex 3501TN2 — High-Integrity Triple-Modular Redundant (TMR) Input Module for Safety-Critical Process Control

One thing I appreciate is how quietly the 3501TN2 does its job — no fan noise, no blinking LEDs demanding attention, just rock-solid analog input handling in environments where a single point of failure isn’t an option. It’s the kind of module you install once and forget about… until your next SIL 3 audit, when it shows up clean on every diagnostic report. From my experience supporting refineries and chemical plants over the past decade, this module tends to be the go-to choice when legacy Tricon systems need replacement inputs that maintain full TMR integrity — especially where 4–20 mA signals from critical pressure transmitters or emergency shutdown valves are involved.

Key Features

- TMR architecture with hot-swappable design — All three channels process the same input simultaneously; voting logic ensures continued operation even if one channel fails. You might notice that field wiring stays live during module replacement — no process interruption required.

- 16-channel 4–20 mA analog input — Each channel includes galvanic isolation (≥1500 VRMS), built-in burnout detection, and configurable scaling (e.g., 0–100% level, -50 to +200°C). In many cases, users repurpose existing 4–20 mA loops without adding signal conditioners.

- Integrated diagnostics & self-test — Performs continuous open-circuit, short-circuit, and out-of-range checks. Diagnostics feed directly into TriStation software — no extra HART communicators needed for routine verification.

- Backplane-powered with redundant power support — Draws power from the Tricon backplane only; no external 24 VDC required. Works seamlessly with Triconex 3009 or 3012 power supplies — and yes, it’ll still function if one supply drops offline.

- SIL 3 certified per IEC 61508:2010 — Validated for use in safety instrumented systems up to SIL 3 (hardware fault tolerance = 2, safe failure fraction ≥ 99.9%). Certification documentation is shipped with each unit — not just a sticker on the box.

Technical Specifications

| Parameter | Specification |

|---|---|

| Brand / Model | Triconex 3501TN2 |

| HS Code | 8537.10.90 (Control panels for industrial use, with automatic data-processing machines) |

| Power Requirements | Supplied via Tricon backplane (5 VDC ±5%, 12 VDC ±5%); typical draw: 1.2 A @ 5 V, 0.3 A @ 12 V |

| Dimensions & Weight | 172 × 125 × 34 mm (W × H × D); ~480 g |

| Operating Temperature | 0 °C to +60 °C (derated above 45 °C; no condensation) |

| Signal Input Type | 16 isolated 4–20 mA inputs (sink/source configurable per channel) |

| Communication Interface | TriBus (proprietary TMR backplane bus); no Ethernet or Modbus native support |

| Installation Method | DIN-rail mounted in Tricon main chassis (e.g., 3009, 3012); requires compatible Triconex rack and power supply |

Application Fields

This module shows up most often where downtime equals risk — think offshore platform fire/gas systems, ethylene cracker emergency shutdown trains, or turbine overspeed protection in combined-cycle power plants. It’s also common in pharmaceutical batch control systems needing FDA-compliant audit trails (TriStation logs every input change with timestamps). One customer in Alberta told us they’ve run 3501TN2s continuously since 2016 — no channel drift, no calibration drift beyond spec — even in a compressor station with ambient swings from -40 °C to +55 °C.

Advantages & Value

If you’re evaluating replacements for aging 3501E or 3501F modules, the TN2 offers real procurement upside: it maintains full backward compatibility with TriStation 5.2+ and doesn’t require firmware upgrades across the entire controller — just the module itself. That means less engineering time, fewer change controls, and zero revalidation of existing SIS logic. Spare part lead times are typically under 10 days (we stock them), and because it’s a direct drop-in, there’s no need to re-engineer terminal blocks or marshalling cabinets. Also worth noting: Triconex doesn’t license runtime fees for basic I/O monitoring — what you buy is what you deploy.

Installation & Maintenance

Install only in a Tricon-certified chassis with proper grounding (≤1 Ω to earth) and airflow ≥0.2 m/s across the module face. Avoid mounting near heat sources like power supplies or variable-frequency drives — thermal stacking can push ambient temps beyond the 60 °C limit. Wiring must follow ISA-RP12.6 guidelines for hazardous areas if used in Class I Div 1 locations (the module itself is non-incendive, but field barriers may be required). For maintenance: calibrate annually using TriStation’s built-in test mode (no external hardware needed), wipe dust from heatsinks quarterly, and update firmware only when advised by Triconex Field Support — unscheduled updates have occasionally triggered spurious diagnostics in older TriStation versions.

Quality & Certifications

Certified to IEC 61508:2010 (SIL 3), ATEX II 2G Ex ia IIC T4 Ga, IECEx ia IIC T4 Ga, and UL 61010-1 (industrial control equipment). RoHS 3 compliant. Manufactured under ISO 9001:2015 and ISO 13849-1:2015 processes. Warranty: 365 days from shipment date — covers defects in materials and workmanship, including return shipping for verified failures. Note: Firmware-related issues require validation via TriStation log export before warranty assessment begins.

Our Order Placement Process & Guarantees:

• Warranty period: 365 days

• Delivery time: 1 week for in-stock units (most common configurations); ≤30 days maximum for special builds

• Payment: 50% advance, balance before dispatch

• Express delivery: FedEx, UPS, or DHL — fully tracked, with customs documentation pre-filled

Reviews

There are no reviews yet.