Description

TRICONEX 3625 – TMR Safety I/O Module for High-Integrity Process Control

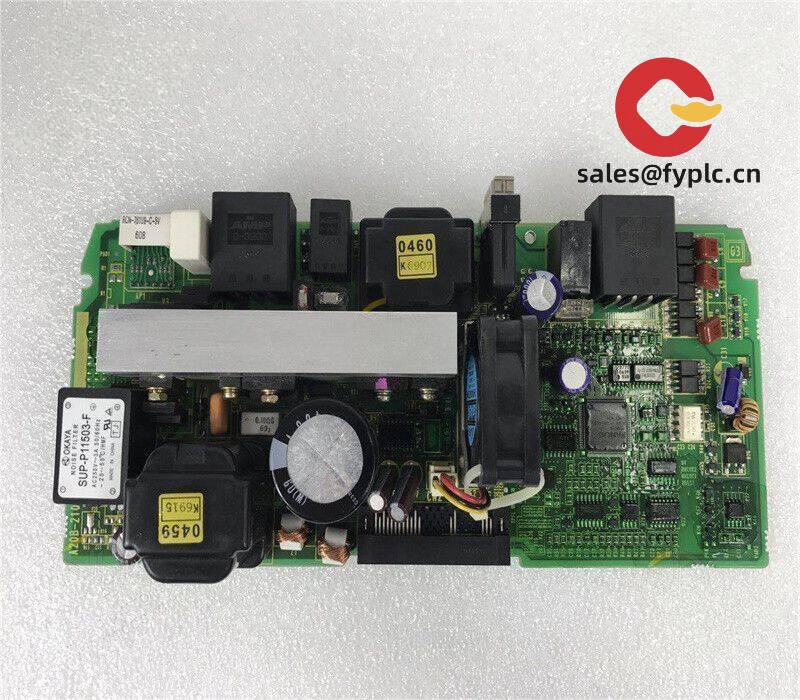

The TRICONEX 3625 is a plug-in I/O module for the Triconex Triple Modular Redundant (TMR) safety system, designed for use in Safety Instrumented Systems (SIS) where continuous operation and fault tolerance matter. From my experience, plants choose this module when they want SIL3-capable reliability with online diagnostics and hot-replace convenience, without disrupting a running unit. It fits the standard Tricon chassis and communicates over the triplicated backplane, so integration into existing Tricon nodes is typically straightforward.

Company’s Order Placement Process and Guarantees

- Warranty: 365 days

- Delivery: 1 week for in-stock; no more than one month at the latest

- Payment: 50% advance payment; full payment prior to delivery

- Express options: FedEx, UPS, DHL

Key Features

- TMR architecture – Triplicated logic paths and voting improve fault tolerance and keep the process running in most single-fault scenarios.

- Hot-replace capability – Module replacement can typically be done online, minimizing unit downtime and maintenance windows.

- Continuous self-diagnostics – Integrated health checks, status LEDs, and diagnostics help maintenance teams spot issues early.

- Backplane integration – Communicates via the Tricon triplicated backplane for deterministic, redundant data exchange.

- SIL3 suitable – When used within the Triconex SIS architecture, it supports IEC 61508 SIL3 applications in many cases.

- Robust design – Industrial-grade components and conformal coating (on applicable revisions) for harsh control-room environments.

- Lifecycle flexibility – Compatible with standard Tricon chassis and power modules, easing spares planning and phased migrations.

Technical Specifications

| Brand / Model | TRICONEX 3625 (Schneider Electric) |

| HS Code | 8538.90 (Parts suitable for 8535/8536/8537 apparatus) |

| Power Requirements | Backplane powered via Tricon chassis (nominal 5 VDC supply provided by system power modules; current draw varies by hardware revision) |

| Dimensions & Weight | Standard Tricon plug-in module; single-wide slot for Tricon rack (fits 19-inch Tricon system chassis) |

| Operating Temperature | Typically 0 to 60 °C (32 to 140 °F) in conditioned control-room environments |

| Signal I/O Types | Safety-related process I/O handled within the TMR architecture; exact channel type and count depend on the 3625 hardware variant and application design |

| Communication Interfaces | Triplicated Tricon backplane; deterministic I/O scan and diagnostics through the system controller |

| Installation Method | Rack-mounted, plug-in to Tricon chassis slot; keyed placement; hot-replaceable under system procedures |

Application Fields

The 3625 is typically deployed across safety-critical units where proof testing and uptime are equally important:

- Oil & Gas: ESD, HIPPS, fire & gas mitigation, burner management interfaces

- Chemicals & Petrochemicals: reactor protection, interlocks, utilities safeguarding

- Power Generation: boiler protection, turbine auxiliaries, balance-of-plant safety loops

- Pharma & Specialty: process safety layers around critical batch operations

One thing I appreciate is how it slots into mixed legacy and newer Tricon nodes, so upgrades can be staged without touching every cabinet at once.

Advantages & Value

- Reliability: TMR voting and continuous diagnostics reduce spurious trips and nuisance alarms.

- Compatibility: Works within standard Tricon chassis alongside controllers (e.g., 3008) and communication modules, which typically simplifies system spares.

- Maintenance efficiency: Hot-replace and clear LED status shorten troubleshooting and turnaround time.

- Total cost control: Extends the life of installed Tricon assets, limiting redesign cost and unnecessary I/O rewiring.

- Supportability: Strong global installed base; documentation and service expertise are widely available.

A maintenance superintendent told me they swapped a 3625 during a live run and shaved a full shift off the planned downtime because the diagnostics isolated the fault before they opened the cabinet. That seems to be the typical experience when procedures are followed carefully.

Installation & Maintenance

- Panel standards: Install in a Tricon system chassis within a clean, ventilated control-room cabinet (19-inch). Maintain adequate airflow and clearance.

- Wiring practices: Follow Triconex grounding, shielding, and segregation rules for safety I/O. Use labeled terminal blocks and verify keying before insertion.

- Hot replacement: Use approved online replacement procedures; confirm controller state, inhibit affected logic where required, and verify post-replacement diagnostics.

- Routine maintenance: Periodic visual inspection, connector reseat if needed, dust removal with dry air, and firmware checks per site standards.

- Proof testing: Align with plant SIF proof-test intervals; capture as-found/as-left results for SIS records.

Quality & Certifications

- SIL3 suitability: When deployed as part of a certified Triconex SIS per IEC 61508/61511.

- CE / UL / CSA: Typically compliant for industrial environments (region and hardware revision dependent).

- RoHS: Compliance may vary by vintage; verify per part revision if required by site policy.

- Warranty: 365-day coverage as stated above.

Suggested Supporting Components

For a clean installation and spare strategy, many sites pair the TRICONEX 3625 with:

- TRICONEX 3008 main processor (controller) for TMR logic execution

- Standard Tricon chassis and power modules for 5 VDC backplane supply

- Appropriate termination assemblies and shielded field cabling per signal type

If you’d like, share your installed Tricon chassis type and the required channel mix; I can double-check 3625 compatibility by hardware revision and line up a practical spare package.

Reviews

There are no reviews yet.