Description

Triconex3664 | Dual Digital Input/Output Module Communication

3664

The Triconex 3664 is a high-performance analog input module widely used in safety-critical industrial control systems, particularly as part of Triconex’s Safety Instrumented System (SIS). Designed for precision, reliability, and redundancy, it plays a critical role in monitoring and processing analog signals from field devices (e.g., sensors, transmitters) to ensure safe and stable operation of industrial processes.

| Label |

Specification |

| Model Number |

3664 |

| Brand |

Triconex |

| Type |

Analog Input Module |

| Input Channels |

16 channels (typically configurable for voltage/current inputs) |

| Input Range |

– Voltage: 0–5 VDC, ±5 VDC, 1–5 VDC

– Current: 4–20 mA, 0–20 mA |

| Resolution |

16 bits (high-precision signal conversion) |

| Accuracy |

±0.1% of full-scale (depends on input range) |

| Redundancy |

Triple Modular Redundancy (TMR) design for fault tolerance |

| Isolation |

Galvanic isolation between channels (typically 500 VDC) |

| Power Supply |

24 VDC (nominal, with surge protection) |

| Operating Temperature |

-20°C to +70°C |

| Communication |

Integrates with Triconex backplane via high-speed serial bus |

| Certifications |

Compliant with IEC 61508 (SIL 3), IEEE standards, and electromagnetic compatibility (EMC) regulations |

3664

-

Triple Modular Redundancy (TMR)

The module uses three independent signal processing paths to detect and reject faults. If one channel fails, the other two continue to provide accurate readings, ensuring uninterrupted operation in critical systems (e.g., oil refineries, chemical plants).

-

High Precision and Noise Immunity

- 16-bit resolution ensures precise conversion of analog signals (e.g., temperature, pressure, flow rates) to digital data for the control system.

- Advanced filtering and isolation techniques minimize interference from electromagnetic and radio-frequency sources (EMI/RFI).

-

Flexible Configuration

- Supports multiple input types (voltage/current) and ranges, adaptable to various field devices.

- Configurable through Triconex’s software tools (e.g., Tricon Expert) for channel scaling, alarms, and diagnostics.

-

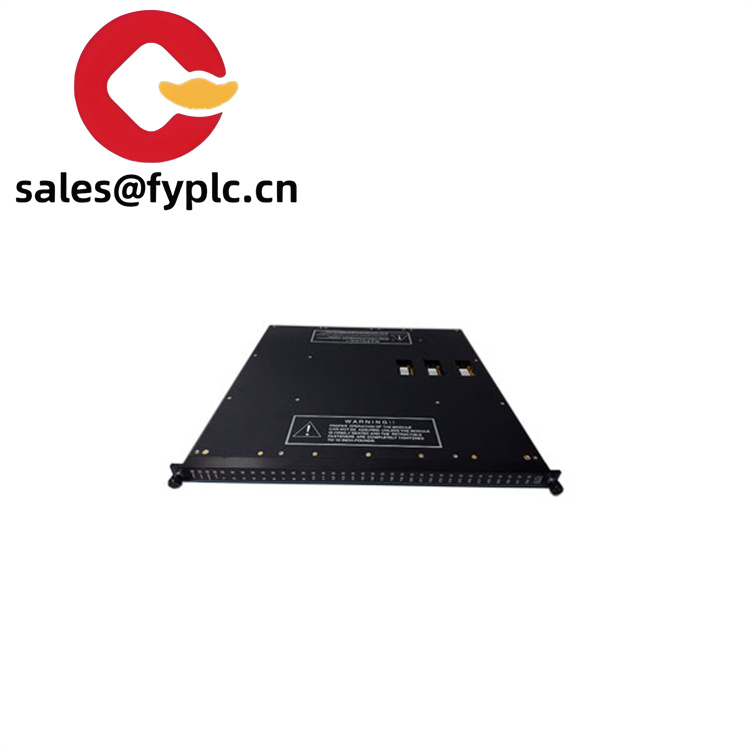

Robust Industrial Design

- Withstands harsh environments (wide temperature range, vibration, humidity).

- Compliant with IP67 for dust and water resistance (when installed in sealed enclosures).

-

Real-Time Diagnostics

Built-in self-diagnostic functions continuously monitor channel health, detecting faults like open circuits, short circuits, or signal drift. Alerts are sent to the control system for timely maintenance.

-

3664

- Oil and Gas: Monitoring pressure/temperature in pipelines, wells, and processing units.

- Power Generation: Tracking steam turbine parameters, boiler levels, and generator conditions.

- Chemical/Petrochemical: Controlling reactor temperatures, flow rates, and safety interlocks.

- Water/Wastewater: Measuring 液位 (liquid level), pH, and flow in treatment plants.

-

For more information, please click on the following link:

Reviews

There are no reviews yet.