Description

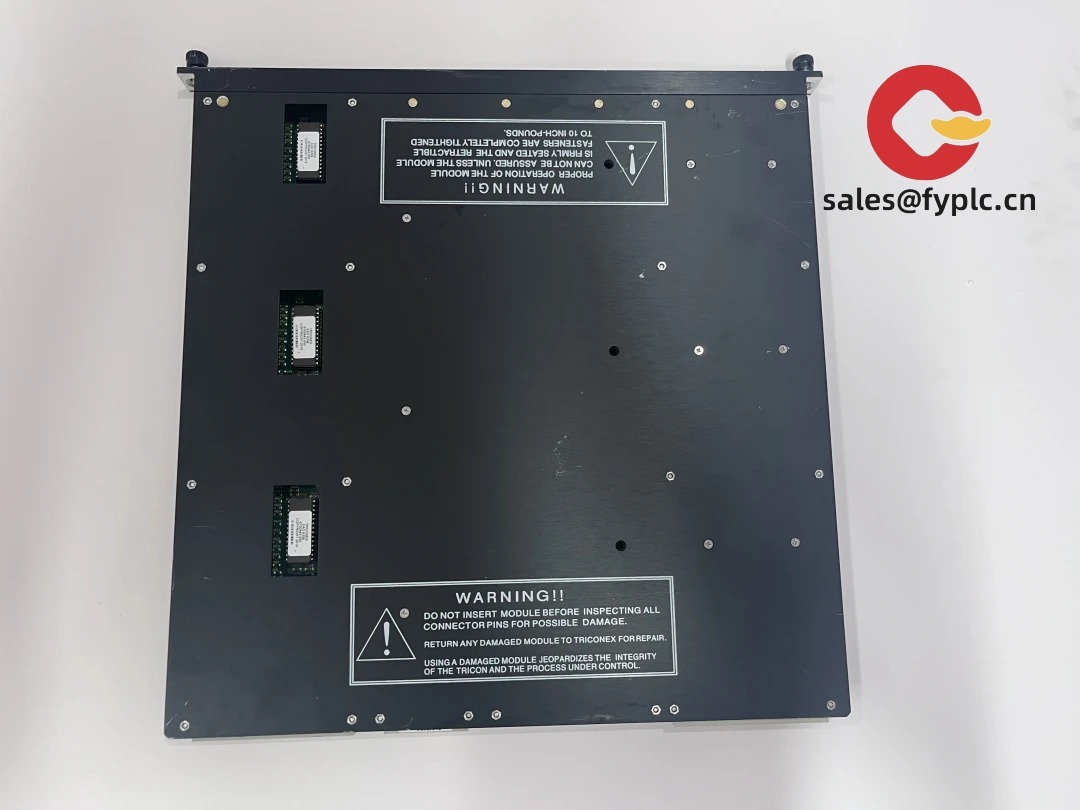

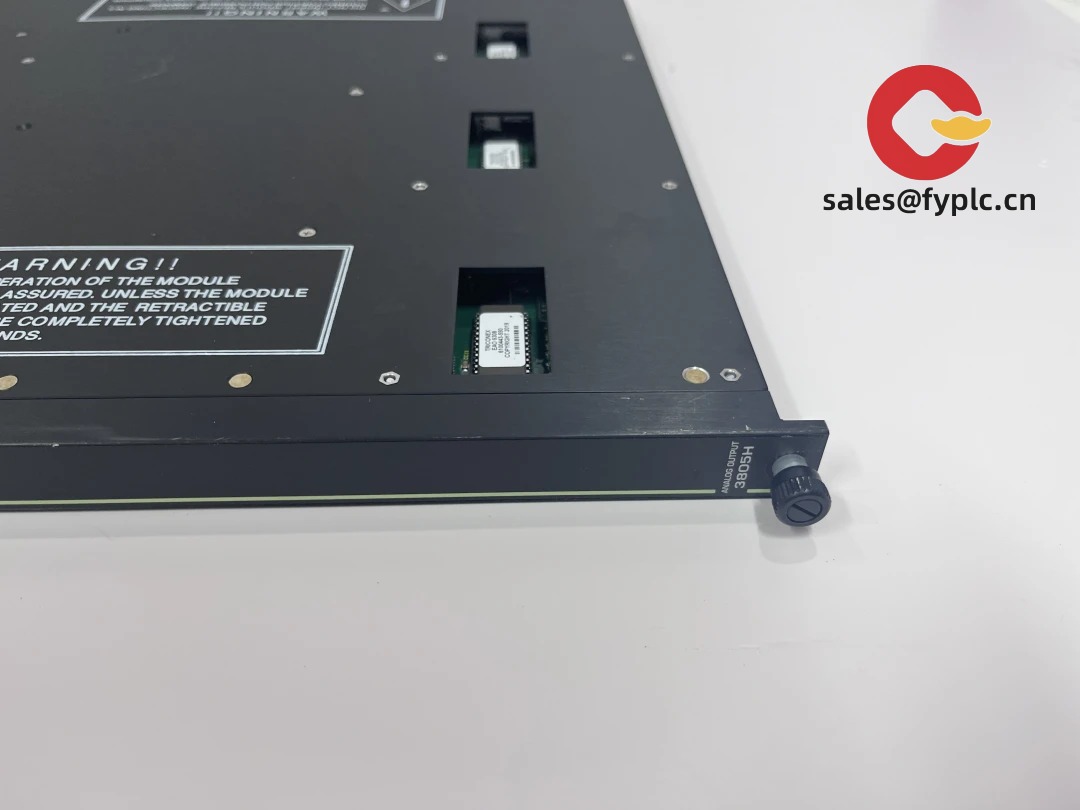

Triconex 3805H — High-Integrity Dual-Channel Analog Input Module for Safety-Critical Process Control

The Triconex 3805H isn’t just another analog input card—it’s the go-to module when your application demands SIL 3 compliance *and* continuous process visibility. I’ve seen it deployed in offshore gas compressors where a single channel failure can trigger shutdowns, and in refinery flare stack monitoring where redundancy isn’t optional—it’s baked into the architecture. From my experience, this module stands out because it doesn’t rely on software voting alone; its hardware-level dual-channel isolation means each input path is electrically and logically independent—right down to separate A/D converters and isolated power domains.

Key Features

- Dual independent 4–20 mA input channels — Each channel has its own galvanic isolation (2500 VRMS), separate scaling, and configurable fault detection (open wire, over-range, under-range). You might notice that unlike some “dual” modules that share reference circuits, the 3805H treats each channel as a fully autonomous sensor interface.

- SIL 3 certified per IEC 61508 & IEC 61511 — Validated for use in safety instrumented systems up to SIS Level 3. It appears that TriStation 5.3+ and Tricon 11.4 firmware are required to maintain full certification scope—something worth confirming during engineering handover.

- Hot-swappable with diagnostic LED status per channel — Red/green/amber indicators show real-time health: green = normal, amber = warning (e.g., minor drift), red = fault (e.g., open circuit or calibration timeout). One thing I appreciate is how quickly field techs spot issues without pulling up TriStation—just a glance at the rail.

- Configurable linearization & sensor burnout detection — Supports user-defined 16-point linearization tables, plus programmable high/low current thresholds for detecting failed transmitters. In many cases, this eliminates the need for external signal conditioners in legacy skid retrofits.

- Integrated HART transparency mode — When enabled, the module passes HART digital signals (at 4–20 mA) through to host systems like DeltaV or Emerson AMS—so you retain device diagnostics without adding a separate HART multiplexer.

Technical Specifications

| Parameter | Specification |

|---|---|

| Brand / Model | Triconex 3805H |

| HS Code | 8537.10.90 (Control panels for industrial automatic controls) |

| Power Requirements | Supplied via Tricon backplane (24 VDC nominal); no auxiliary power needed |

| Dimensions & Weight | 19.5 cm × 12.7 cm × 4.5 cm (W×H×D); ~320 g |

| Operating Temperature | 0 °C to +60 °C (derated above 40 °C for extended SIL 3 operation) |

| Signal Input Type | Two independent 4–20 mA DC inputs, sink or source configurable, HART-transparent |

| Communication Interface | Integrated into Tricon system bus (TriBus); no external comms required |

| Installation Method | DIN-rail mounted in Tricon chassis (e.g., TRICONEX 4352, 4353); requires compatible power supply module |

Application Fields

This module shows up most often where uptime meets consequence—think upstream oil & gas compressor stations needing emergency shutdown validation, chemical reactor temperature interlocks, or LNG liquefaction train level monitoring. A customer once told me they replaced three aging single-channel cards with one 3805H and cut cabinet space by 40%, while gaining built-in diagnostics that reduced loop-check time by half during commissioning. It’s also common in pharmaceutical clean utility systems (e.g., pure steam pressure monitoring), where regulatory auditors ask for evidence of dual independent sensing—not just software redundancy.

Advantages & Value

- No hidden integration tax — Works natively with Tricon hardware and TriStation engineering tools. No middleware, no license fees for basic functionality. That typically translates to faster FAT/SAT execution and fewer third-party compatibility surprises.

- Lower lifecycle cost than patching legacy systems — While the upfront price sits above entry-level analog cards, customers report 2–3 year payback from avoided spares inventory (replacing multiple SKUs with one) and reduced troubleshooting labor during unplanned outages.

- Backward-compatible within Tricon generations — Verified to operate in both older TRICONEX 4200-series racks and newer 43xx platforms (with appropriate firmware). So if your site runs mixed-gen controllers, this module bridges the gap without forcing a full controller refresh.

- Responsive technical support — Tri-Services engineers routinely assist with loop verification scripts and custom linearization tables—something I’ve seen make a real difference during tight commissioning windows.

Installation & Maintenance

Mount only in TriStation-certified cabinets meeting NEMA 12/IP54 minimum (for indoor use) or NEMA 4X/IP66 if exposed to washdown environments. Ensure ambient airflow around the chassis—Tricon recommends ≥10 cm clearance above/below modules and cabinet internal temp ≤55 °C. Wiring must use twisted-pair, shielded cable (Belden 8761 or equivalent), with shields grounded at the module end only. Avoid routing analog cables parallel to VFD outputs or AC power lines—keep separation ≥30 cm or use physical barriers.

For maintenance: verify zero/span every 12 months (or after major environmental shifts); clean dust filters quarterly; update Tricon firmware only during planned outages—some versions introduce subtle timing changes affecting fast-loop applications. Calibration certificates are traceable to NIST, and we recommend keeping archived copies of TriStation configuration backups before any firmware change.

Quality & Certifications

Certified to IEC 61508 (SIL 3), IEC 61511 (SIL 3), ATEX II 2G Ex ia IIC T4 Ga, UL 61010-1, CSA C22.2 No. 61010-1, and RoHS compliant. Manufactured under ISO 9001:2015 and ISO 13849-1 processes. Warranty is 365 days from shipment date—covers defects in materials and workmanship, including replacement of faulty units with same or functionally equivalent models. We don’t prorate; if it fails within the year, it gets replaced outright.

Our Order Placement Process & Guarantees

- Delivery: 1 week for in-stock units; up to 30 days maximum for special configurations or firmware builds.

- Payment: 50% advance payment required to initiate order processing; balance due prior to shipment.

- Shipping: Fedex, UPS, or DHL express—fully tracked, with customs documentation pre-cleared for most destinations.

Reviews

There are no reviews yet.