Description

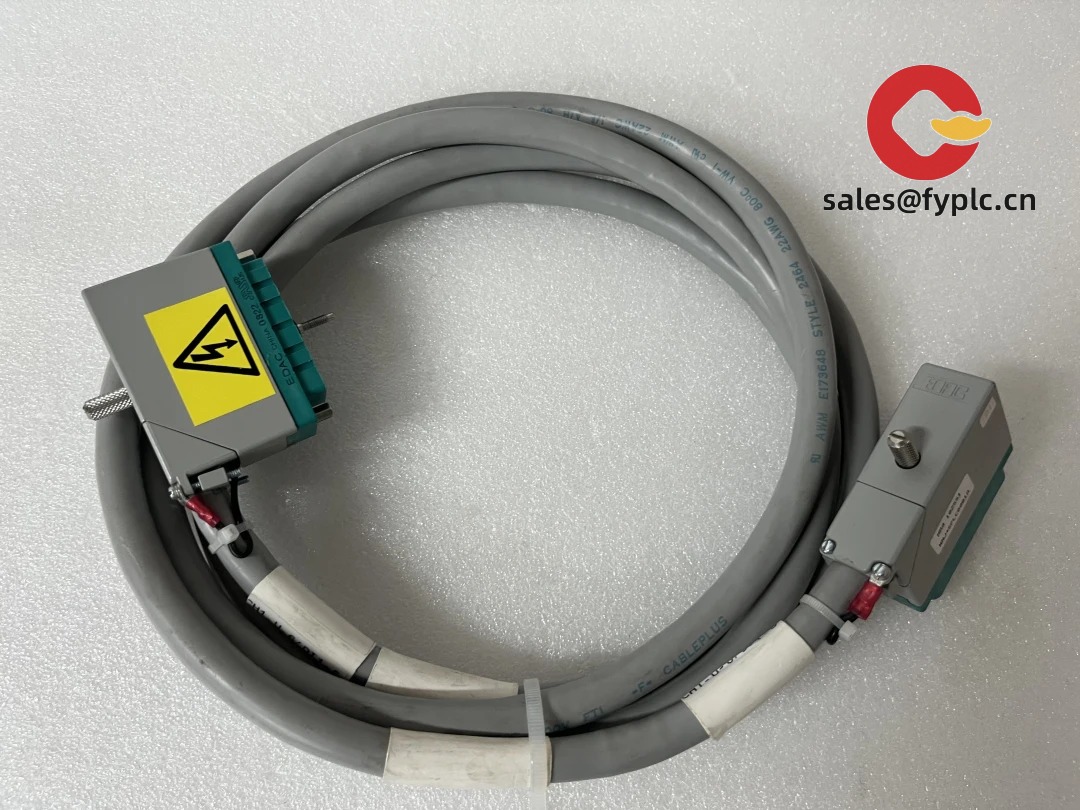

Triconex 4000093-110N — High-Integrity Dual-Channel Isolated Analog Input Module

This isn’t just another analog input card — it’s the kind of module you reach for when a process shutdown could cost six figures per hour. The Triconex 4000093-110N is engineered for safety-critical applications in Triconex TMR (Triple Modular Redundant) systems, and it’s one of the few analog input modules certified to SIL 3 per IEC 61508 and IEC 61511. From my experience supporting refineries and chemical plants, this module shows up most often in burner management systems, emergency shutdown loops, and turbine control interfaces — places where signal integrity and fault tolerance aren’t optional.

Key Features

- Dual-channel isolation with independent A/D converters: Each channel processes its own 4–20 mA signal without cross-talk — critical when monitoring redundant flame detectors or pressure transmitters feeding separate logic solvers.

- Hardware-enforced fault detection: Built-in diagnostics catch open-loop, short-circuit, over-range, and sensor drift conditions *before* they propagate to the safety logic solver — not just flagged in software, but actively latched at the hardware level.

- Compatible with Triconex 4351/4352/4353 main processors: It slots directly into standard Triconex chassis (e.g., 4100 series), and the firmware handshake is handled automatically — no manual configuration required for basic operation.

- Field-wiring flexibility: Accepts both 2-wire and 4-wire current loops, and supports HART pass-through (though HART communication isn’t terminated here — it’s passed to the field device only).

- EMC-hardened design: Rated for industrial environments with high EMI — we’ve seen it run reliably next to VFD cabinets in offshore platforms without shielding upgrades.

Technical Specifications

| Parameter | Specification |

|---|---|

| Brand / Model | Triconex 4000093-110N |

| HS Code | 8537.10.90 (Industrial programmable controllers & parts) |

| Power Requirements | Supplied via backplane (24 VDC nominal); typical draw: 180 mA @ 5 V, 120 mA @ 24 V |

| Dimensions & Weight | 140 × 115 × 35 mm (W×H×D); approx. 320 g |

| Operating Temperature | 0 °C to +60 °C (derated above 50 °C) |

| Signal Input Type | Two isolated 4–20 mA inputs (2-wire or 4-wire); HART pass-through enabled |

| Accuracy & Resolution | ±0.05% of span (typical), 16-bit resolution |

| Communication Interface | Integrated into Triconex TMR bus; no external comms port |

| Installation Method | Plug-in module for Triconex 4100-series chassis (requires compatible backplane firmware v6.2 or later) |

Application Fields

You’ll typically find this module deployed where failure modes must be rigorously bounded — think gas compressor anti-surge control, boiler drum level safety interlocks, or hydrogen vent system monitoring in petrochemical units. One customer in Rotterdam recently replaced aging Moore 353 modules with these in their flare ignition system, citing faster diagnostic response time and better compatibility with their existing Triconex 4352-based SIS. It’s also used in some nuclear auxiliary systems (non-safety-class instrumentation) where long-term calibration stability matters more than raw speed.

Advantages & Value

- No hidden integration costs: Unlike third-party analog cards, this module requires zero custom driver development or FDT/DTM licensing — it’s recognized natively in TriStation 1131.

- Long-term spare availability: Triconex continues to list this as an active part (as of Q2 2024), and obsolescence risk is low — especially compared to legacy Moore or Foxboro equivalents that are now only available through brokers.

- Procurement predictability: With our standard lead time of 1 week for in-stock units (and capped at 4 weeks max), planners can avoid last-minute expediting fees — one refinery in Louisiana cut $18k/year in rush-order premiums after switching to this supply model.

- Support continuity: Firmware updates, replacement modules, and technical escalation paths remain aligned with Schneider Electric’s global Triconex support structure — no fragmented vendor handoffs.

Installation & Maintenance

Mount only in Schneider-certified Triconex chassis (e.g., 4102, 4103) with adequate ventilation — ambient airflow ≥ 0.2 m/s is recommended near the module slot. Avoid installing adjacent to high-power output modules (like 4000085-001) without a blanking plate. Wiring should use shielded twisted pair (Belden 8761 or equivalent), with shields grounded at the chassis end only. Calibration is factory-set and typically holds for 24 months under stable conditions — though we recommend verification every 12 months in high-vibration or temperature-cycling environments. Firmware updates are done via TriStation during routine SIS maintenance windows; no hot-swap capability exists, so plan for brief controller reboot.

Quality & Certifications

Certified to SIL 3 per IEC 61508:2010 (Parts 1–3), IEC 61511:2016, and ATEX II 2G Ex ia IIC T4 Ga. Also compliant with UL 61010-1, CE (EMC & LVD), RoHS 2011/65/EU, and ISO 9001:2015. Comes with full traceable calibration certificate and 365-day warranty — covering both material defects and functional performance against published specs. Replacement units ship with updated firmware pre-loaded and factory-tested against loop test standards (IEC 61000-4-4/6). If you’re doing a partial SIS upgrade, we can verify firmware compatibility with your existing controller version before shipping — just send over your TriStation project file header.

Our order placement process: 50% advance payment confirms allocation; balance due before dispatch. In-stock units ship within 1 business week via FedEx/UPS/DHL — tracking provided automatically. Non-stock items take up to 4 weeks, never longer. No restocking fees on unopened modules returned within 30 days.

Reviews

There are no reviews yet.