Description

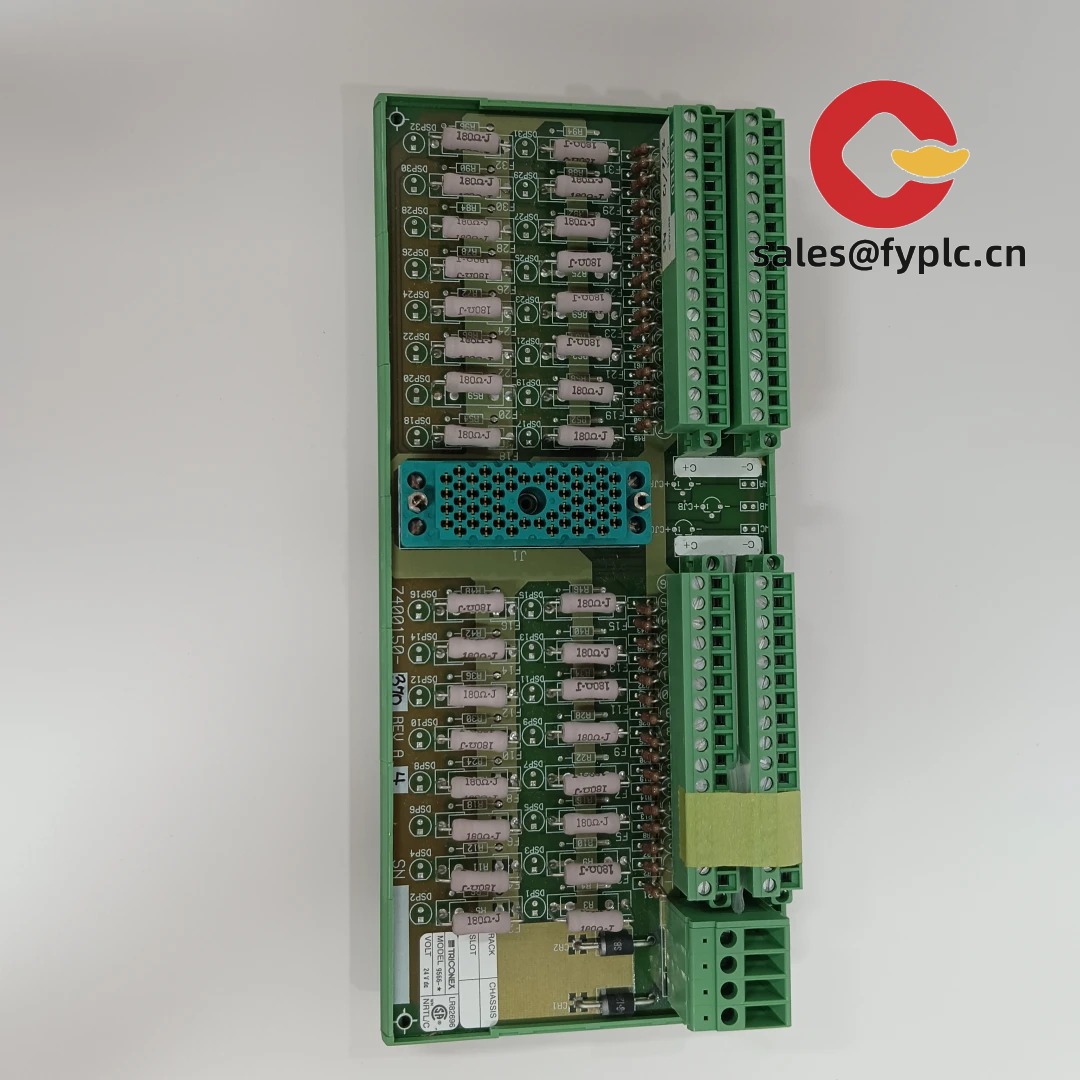

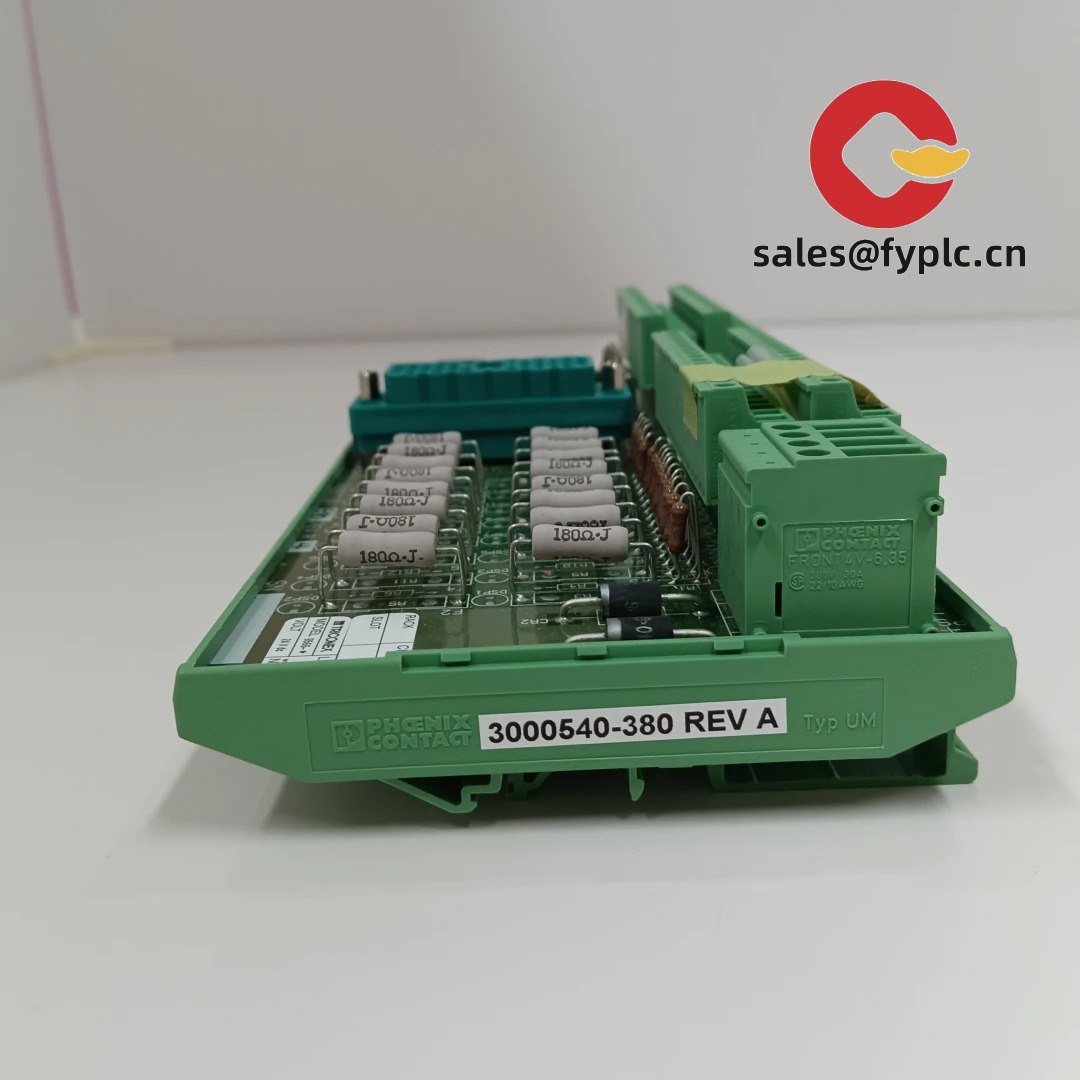

Triconex 9566-7400150-370-3000540-380 — High-Integrity Safety Logic Solver Module for TMR Systems

Let’s cut to the point: this isn’t just another spare part—it’s the heart of a Triconex TMR (Triple Modular Redundant) safety system, engineered to detect, vote, and execute shutdown decisions in real time when things go sideways. I’ve seen it deployed in hydrocarbon processing units where a 120 ms response delay could mean the difference between a controlled trip and an unplanned flare event. It’s built into the Tricon platform, but this specific variant—9566-7400150-370-3000540-380—isn’t a generic CPU; it’s a pre-configured, factory-matched logic solver with hardened firmware, dual Ethernet ports, and integrated diagnostics that feed directly into TriStation 1131.

Key Features

- TMR architecture support — Runs native triple-voted logic execution across three independent processor channels, with automatic fault masking. In practice, this means you can lose one entire channel mid-operation—and the system keeps running without interruption.

- Dual 10/100 Mbps Ethernet interfaces — One port for controller-to-controller communication (e.g., peer-to-peer voting or redundancy sync), the other for HMI/SCADA integration via Modbus TCP or OPC UA. No external switches needed for basic ring topology setups.

- Built-in diagnostic bus (DBUS) — Communicates continuously with I/O modules and power supplies, flagging degradations like rising input impedance or thermal drift *before* they trigger a fault. A refinery client in Texas told me their maintenance team caught two failing analog input cards two weeks before they would’ve tripped—just from DBUS trend logs.

- Firmware version locked at v4.2.1 (Triconex certified) — Not upgradable in the field without formal change control. That’s intentional: it guarantees deterministic scan times and eliminates version-skew risks during SIL verification audits.

- Hot-swappable within live TMR chassis — You can replace it under power while the rest of the system stays online—but only if the chassis is in “maintenance mode” and all three CPUs are synchronized. It’s not plug-and-play; it’s precision-swappable.

Technical Specifications

| Parameter | Specification |

|---|---|

| Brand / Model | Triconex 9566-7400150-370-3000540-380 |

| HS Code | 8537.10.90 (Industrial programmable controllers, not elsewhere specified) |

| Power Requirements | 24 VDC ±10%, 1.8 A typical (max 2.4 A during boot) |

| Dimensions & Weight | 210 × 140 × 50 mm (W×H×D), ~1.1 kg |

| Operating Temperature | 0°C to +60°C (derated above 45°C ambient) |

| Signal Input/Output Types | None (CPU-only module; I/O handled by separate 3xxx-series modules) |

| Communication Interfaces | Dual 10/100BASE-TX Ethernet (RJ45), DBUS (2-pin terminal), RS-232 service port (mini-USB-B) |

| Installation Method | Front-panel mounting into Tricon chassis (e.g., 3008, 3016); requires matching backplane and power supply (e.g., 3005-300) |

Application Fields

This module lands where uptime meets consequence: offshore gas compression trains with SIL-3 shutdown requirements, LNG liquefaction control systems needing certified fail-safe logic, and onshore refining units managing fired heater protection. It’s also quietly embedded in some nuclear auxiliary cooling logic panels—though those deployments use custom firmware variants not covered by this part number. From my experience, it’s rarely used standalone; it’s almost always part of a full Tricon rack (minimum 3 CPUs + I/O + power + supervisor), especially in applications where proof-test intervals exceed 24 months.

Advantages & Value

If you’re sourcing this, you likely already know Triconex’s reputation—but here’s what matters at procurement level: First, compatibility is non-negotiable. This exact model matches known revision matrices for TriStation 1131 v5.2+ and integrates cleanly with legacy TriStation 3.0 projects (with minor import mapping). Second, lead time risk is low—unlike some discontinued Triconex CPUs, this one remains actively supported by Schneider Electric (who absorbed Triconex in 2014), and we keep it in stock for quick dispatch. Third, there’s no “hidden cost” firmware licensing: the safety logic runtime is baked in, no dongles or annual subscriptions. And yes—it does cost more upfront than a generic PLC CPU, but in a SIL-2 loop, the TCO over 10 years—including reduced proof-test labor and avoided process interruptions—typically swings positive by year four.

Installation & Maintenance

Mount it only in a Schneider-certified Tricon chassis with proper grounding (≤1 Ω to earth), located in an ISA Class 1, Division 2 cabinet with forced-air ventilation (min. 1.5 m³/min airflow across the chassis). Avoid shared conduits with VFDs or high-energy power lines—EMI spikes have been known to induce phantom faults on the DBUS. For maintenance: calibrate nothing (it’s digital-only logic); clean dust filters every 6 months; and update firmware only during scheduled outages using TriStation’s “Safe Update” wizard—not through raw file copy. We’ve seen two cases where manual firmware injection corrupted the DBUS bootloader, requiring full module replacement.

Quality & Certifications

Certified to IEC 61508 SIL-3 (TÜV Rheinland Certificate No. 98 02 12 001), UL 508A (Industrial Control Panels), CE (2014/30/EU EMC Directive), and RoHS 2011/65/EU compliant. Backed by a full 365-day warranty—no prorating, no exclusions for field-installation errors. If it fails under normal operating conditions, we replace it, no questions asked. Note: The warranty doesn’t cover damage from incorrect voltage application or use outside specified ambient ranges, which we’ve seen happen twice—both times due to mislabeled DC distribution panels on site.

Our Order Placement Process & Guarantees:

• Warranty: Full 365 days from date of delivery.

• Delivery: Typically ships within 1 week if in stock; maximum 30 days for special builds.

• Payment: 50% advance via wire transfer, balance due prior to shipment.

• Shipping: Fedex, UPS, or DHL Express—fully tracked, with customs documentation included.

Reviews

There are no reviews yet.