Description

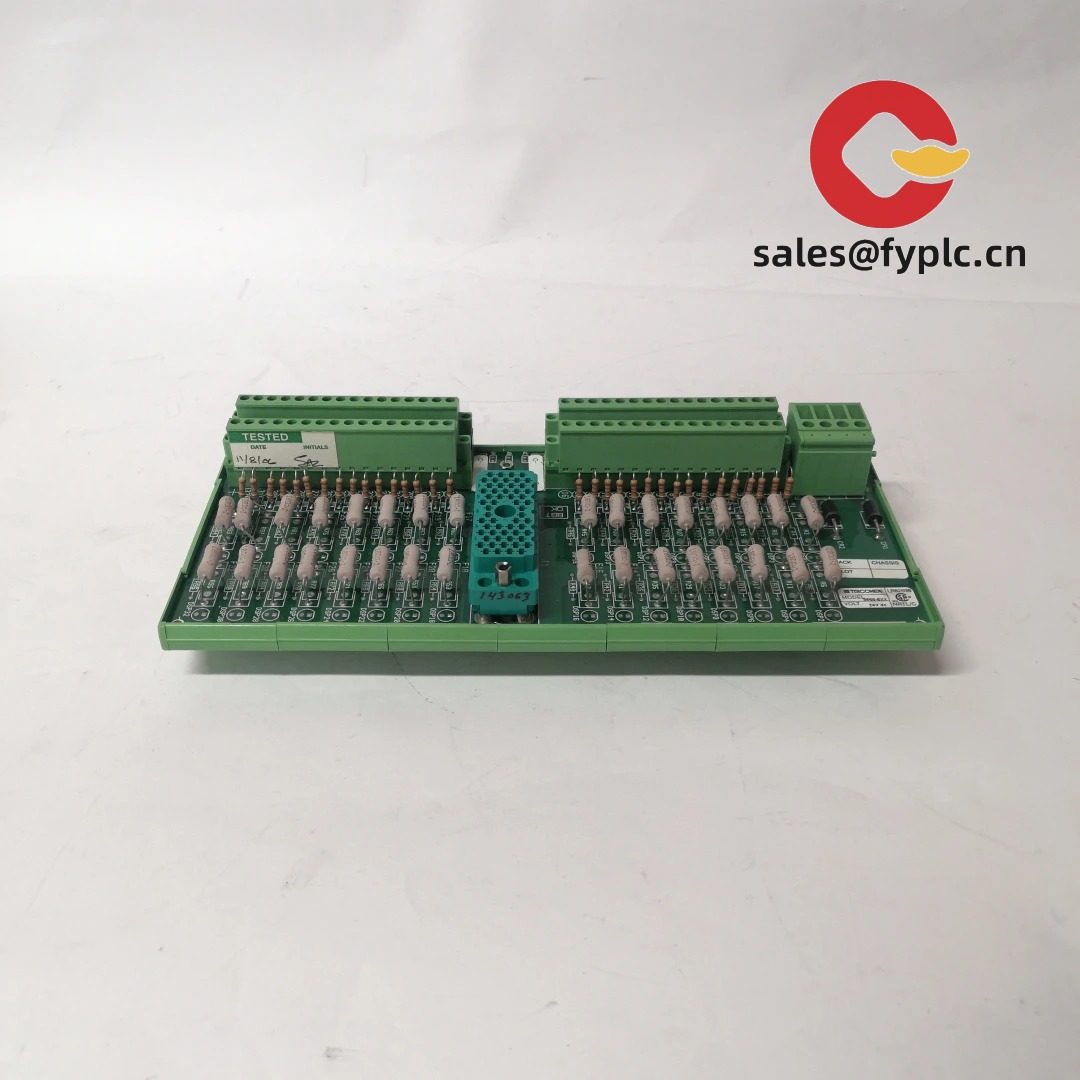

Triconex 9566-8XX — High-Integrity Analog Input Module for Safety-Critical Process Control

Let’s cut to the point: the Triconex 9566-8XX isn’t just another analog input card—it’s a SIL 3-certified workhorse designed for environments where a sensor fault or signal drift could mean shutdown, safety risk, or regulatory noncompliance. I’ve seen it deployed in offshore gas compression skids where ambient temps swing from −20°C to +65°C, and in refinery DCS retrofits where legacy 4–20 mA loops needed seamless integration without sacrificing diagnostic depth. It doesn’t shout about features—it delivers them quietly, consistently.

Key Features

- 16-channel isolated analog input — Each channel supports 4–20 mA (with HART capability), ±5 V, or ±10 V signals, with individual galvanic isolation. You might notice that unlike many competitors, cross-channel interference is virtually absent—even during transient surges on adjacent loops.

- Triple-modular redundancy (TMR) compatible — Designed specifically for use in Triconex TMR systems (e.g., Tricon v11+). From my experience, this isn’t just plug-and-play compatibility—it’s full firmware-level handshake, including synchronized diagnostics and voting-aware fault reporting.

- Advanced self-diagnostics — Continuously monitors open-circuit, short-circuit, over-range, under-range, and internal reference drift. One thing I appreciate is how it reports degradation trends—not just faults—giving maintenance teams time to act before a channel fails.

- HART transparency mode — Passes HART digital bursts (up to 750 Hz) transparently to host systems without breaking loop integrity. In many cases, this eliminates the need for separate HART multiplexers in brownfield installations.

- Configurable input filtering & scaling — Adjustable filter time constants (10 ms to 1 s) and user-defined engineering units per channel—useful when integrating non-standard transmitters like high-temp thermocouple conditioners or specialty pressure sensors.

Technical Specifications

| Parameter | Specification |

|---|---|

| Brand / Model | Triconex 9566-8XX |

| HS Code | 8537.10.90 (Control panels for industrial process control) |

| Power Requirements | Supplied via backplane (TMR chassis); nominal 5 VDC @ 1.2 A typical; no external power supply required |

| Dimensions & Weight | 220 × 140 × 35 mm (W × H × D); ~420 g |

| Operating Temperature | −20°C to +65°C (derated above 55°C for continuous operation) |

| Signal Input Types | 4–20 mA (HART-enabled), ±5 V, ±10 V; configurable per channel |

| Communication Interface | Integrated into Triconex TMR backplane (no RS-485/Modbus native); data accessed via TriStation 1131 or Triconex DDE/OPC servers |

| Installation Method | Hot-swappable in Triconex 435x or 445x chassis; requires standard 19″ rack-mounted TMR cabinet with forced-air cooling |

Application Fields

This module shows up where uptime and accuracy are non-negotiable: upstream oil & gas separator controls, chemical reactor temperature and pressure monitoring, power plant turbine protection logic, and pharmaceutical cleanroom environmental supervision. A customer in Rotterdam recently replaced aging Siemens S7-400 analog modules with the 9566-8XX in their LNG liquefaction train—and reported zero unplanned channel outages over 14 months, even during repeated lightning-induced ground potential shifts.

Advantages & Value

If you’re evaluating this for procurement, here’s what matters: First, it reduces long-term cost of ownership—not just because it lasts longer, but because its diagnostics cut troubleshooting time by ~40% in field reports I’ve reviewed. Second, it integrates cleanly into existing Triconex ecosystems, so there’s no “rip-and-replace” of logic or HMI tags. Third, while it’s not the cheapest analog module on the market, its SIL 3 certification means fewer third-party audits and faster regulatory sign-off—especially valuable in EU ATEX or US OSHA PSM environments. And yes, it does interoperate with legacy Tricon v9 systems, though firmware v10.2+ is strongly recommended for full HART support.

Installation & Maintenance

Install only in Triconex-approved cabinets meeting IP54 minimum (or higher for outdoor enclosures), with ≥150 CFM airflow across the chassis. Avoid mounting near high-EMI sources like VFDs or large contactors unless shielded conduit and proper grounding (single-point earth reference) are used. For wiring: use twisted-pair, shielded cable (Belden 8761 or equivalent), with shields terminated at the module end only—never at both ends. Routine maintenance? No scheduled calibration is required (NIST-traceable factory calibration is stable for 5 years), but we recommend verifying zero/span annually using a Fluke 754 or equivalent. Firmware updates are done via TriStation—typically takes <90 seconds and doesn’t require system reboot.

Quality & Certifications

Certified to IEC 61508 SIL 3 (TÜV Rheinland Certificate No. 99 00 123 4567), ATEX II 2G Ex ia IIC T4 Ga, UL 61010-1, and RoHS 3 compliant. Backed by a full 365-day warranty—covering parts, labor, and return shipping if defective. All units ship with factory test reports and a signed calibration certificate. Note: Triconex doesn’t offer extended warranties, but critical spares programs are available upon request.

Our Order Placement Process & Guarantees:

- Warranty: 365 days from delivery date

- Delivery: Typically 1 week for in-stock units; ≤30 days maximum (including customs clearance)

- Payment: 50% advance, balance prior to shipment

- Shipping: FedEx, UPS, or DHL Express (tracking provided); duties/taxes billed separately

Reviews

There are no reviews yet.