Description

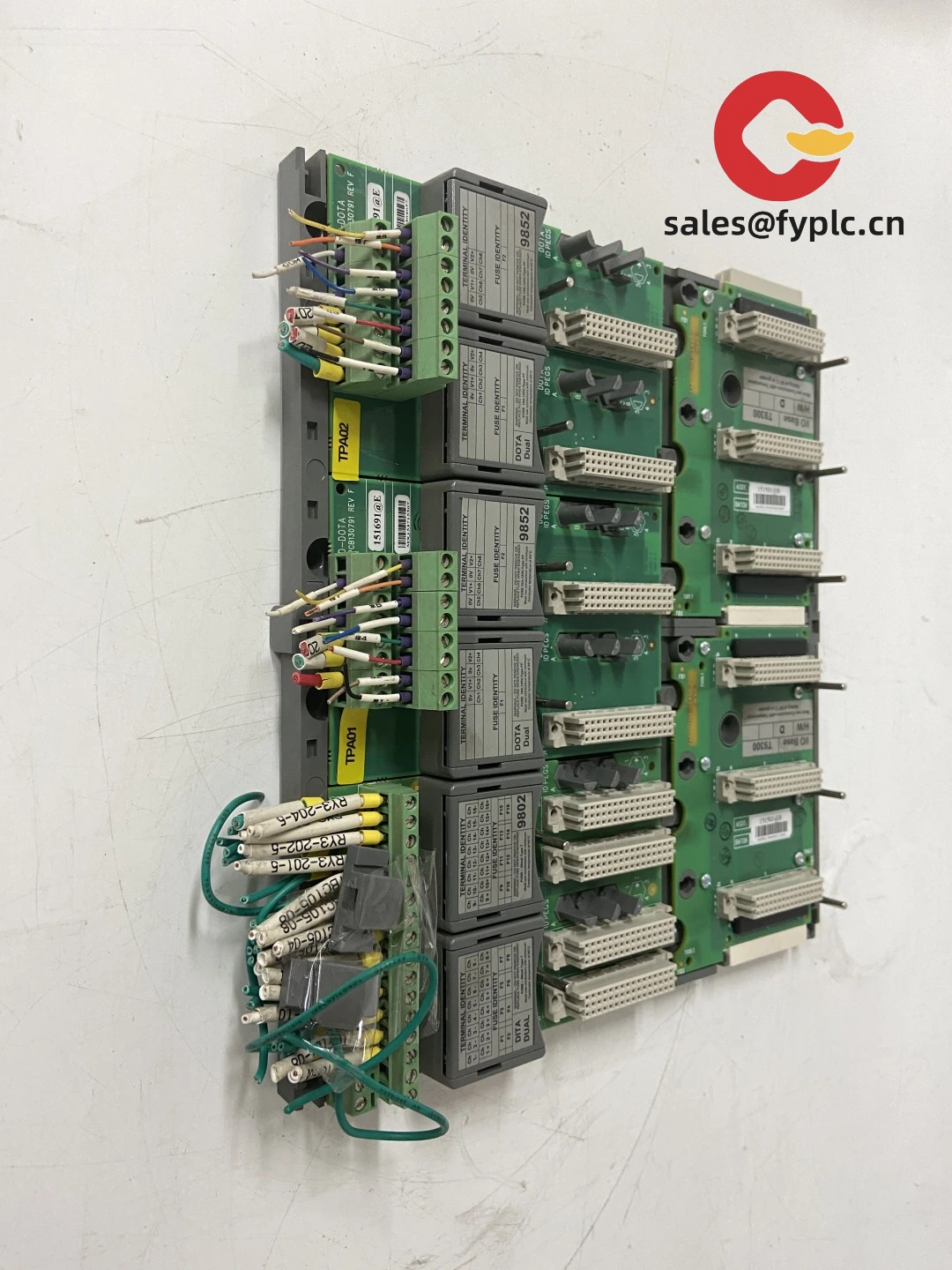

Triconex 9802-1-9852-2 – Field Termination & System Cable Assembly for Tricon SIS I/O

The Triconex 9802-1-9852-2 is used as a field termination and cable assembly pairing for Tricon safety system I/O. From my experience, maintenance teams rely on this style of FTA/cable set to make swap-outs quick—no rewiring at the field and no risky improvisation inside the cabinet. You might notice that it keeps the wiring tidy, shields sensitive signals, and preserves the original channel mapping to the Tricon chassis.

Company’s Order Placement Process and Guarantees

- Warranty period: 365 days

- Delivery time: 1 week for in-stock; no more than 1 month at the latest

- Payment method: 50% advance payment; full payment for delivery

- Express delivery methods: FedEx, UPS, DHL

Key Features

- Purpose-built for Tricon I/O – Mates with the appropriate Triconex card and preserves channel order to reduce commissioning time.

- Passive, reliable termination – Screw terminals for field wiring with clear labeling; no external power required.

- Shielded interconnection – System cable typically provides robust shielding and strain relief to help minimize noise on long runs.

- Service-friendly – Predefined connectors mean the assembly drops in with minimal tools; helpful during hot-cutover windows.

- Cabinet efficiency – Clean routing and compact profile improve airflow and simplify troubleshooting during outages.

Technical Specifications

Specs below reflect what you typically see on Triconex FTA/cable assemblies of this series. If you share your I/O card type and cabinet layout, we can validate fit before shipment.

| Brand / Model | Triconex 9802-1-9852-2 |

| HS Code | 8538.90 (Parts suitable for use with industrial control equipment) |

| Power Requirements | None (passive field termination assembly and interconnecting cable) |

| Dimensions & Weight | Typical compact panel/DIN-rail footprint; approx. 250 × 100 × 40 mm, ~0.5 kg (model-dependent) |

| Operating Temperature | -20 to +60 °C (typical control cabinet environment) |

| Signal Input/Output Types | Field screw terminals; channel type follows the paired Triconex I/O card (DI/DO or analog, as applicable) |

| Communication Interfaces | System cable to Tricon chassis/card (model-dependent connector; shielded) |

| Installation Method | Panel or 35 mm DIN-rail mounting; screw terminals for field wiring with labeled channel IDs |

Application Fields

Used wherever Tricon safety systems interface with field devices, especially where tidy marshalling and fast maintenance matter:

- Refining and petrochemical units linking SIS I/O to limit switches, transmitters, and solenoids

- Gas plants and pipelines with mixed discrete/analog signals that benefit from shielded terminations

- Power generation (BOP skids) where scheduled outages demand predictable swap times

- Pharma and specialty chemicals seeking clean, documented wiring for validation

Advantages & Value

- Reliability – Passive terminations tend to be robust and easy to verify during loop checks.

- Compatibility – Built for Tricon I/O; in many cases it avoids ad‑hoc adapters or rewiring during service.

- Cost & time savings – Shortens turnaround during planned shutdowns and reduces troubleshooting hours later.

- Procurement confidence – Label traceability and a 365‑day warranty help de‑risk critical spares planning.

Installation & Maintenance

- Environment – Mount inside a ventilated cabinet (IP54 or better recommended). Keep clear of high‑EMI conductors and VFD outputs.

- Wiring – Land field wires per channel labels; torque terminal screws to spec and maintain proper shielding/grounding.

- Cable routing – Separate low‑level analog from high‑energy circuits; maintain bend radius and strain relief on the system cable.

- Checks – Perform continuity and insulation checks; run loop tests from the Tricon controller to confirm channel mapping.

- Upkeep – Periodically re‑tighten terminals, clean dust, and inspect for any jacket or connector wear. No calibration required.

Quality & Certifications

- CE and RoHS compliant components (typical for termination assemblies)

- UL/cUL suitability for industrial control panels, where applicable

- Manufacturer’s warranty: 12 months from shipment

If you can share the exact Tricon I/O card part number and cabinet tag, we’ll double‑check the 9802-1-9852-2 pairing so installation is a straightforward drop‑in.

Reviews

There are no reviews yet.