Description

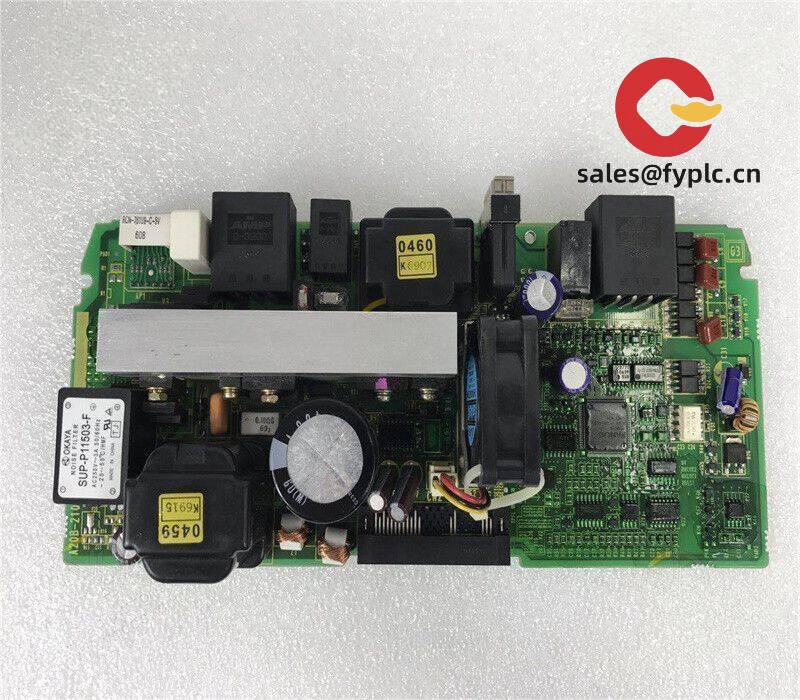

TRICONEX AI3351 (AI3000 Series) – Safety-Critical Analog Input Module for Tricon Systems

The TRICONEX AI3351, part of the AI3000 analog input family, is designed for Triconex Tricon safety systems where high availability and deterministic performance matter. From my experience, this module fits seamlessly into Tricon 3008/v10 chassis and provides stable acquisition of plant analog signals for Safety Instrumented Systems (SIS), Emergency Shutdown (ESD), and high-integrity control loops. You might notice that users lean on the AI3351 when they need reliable, triplicated input paths and continuous diagnostics without sacrificing throughput.

Company’s Order Placement Process and Guarantees

- Warranty: 365 days coverage

- Delivery: In-stock items ship in about 1 week; no more than one month at the latest

- Payment: 50% advance payment; full payment prior to delivery

- Express options: FedEx, UPS, DHL

Key Features

- TMR architecture compatibility – Works within the Triconex triple-modular-redundant (TMR) framework for fault tolerance and high availability.

- Industrial analog signal support – Typically used for standard plant signals (e.g., 4–20 mA or voltage ranges) with robust filtering and diagnostics.

- Backplane-powered – No external power feed; the module draws power from the Tricon chassis backplane for clean, managed supply.

- Hot-swap serviceability – In most cases, replacement is possible under power when following Triconex procedures, minimizing downtime.

- Health LEDs and self-test – Front-panel indication helps technicians quickly judge module state, which reduces time-to-diagnose on site.

- Shielded termination practice – Intended for use with Triconex termination assemblies and shielded cabling to reduce noise pickup in harsh environments.

Technical Specifications

| Brand / Model | TRICONEX AI3351 (AI3000 Series), for Tricon 3008/v10 systems |

| HS Code | 853890 (Parts for electrical control/switching apparatus) |

| Power Requirements | Supplied via Triconex system backplane; no external power input |

| Operating Temperature | Typically 0 to 60°C (32 to 140°F) in a ventilated enclosure |

| Signal Input Types | Analog inputs; commonly used for 4–20 mA and voltage ranges (refer to module revision for exact ranges and channel count) |

| Communication Interfaces | Triconex TMR backplane bus (no external comm ports on the module) |

| Installation Method | Single-slot card for Tricon chassis; connects to external field wiring via Triconex termination assemblies |

| Dimensions & Weight | Standard Triconex single-slot form factor; typically under 1.2 kg |

Application Fields

The AI3351 is typically deployed in SIL-rated safety and high-availability control environments. Common use cases include:

- Oil & Gas: ESD, HIPPS, burner management, flare monitoring

- Refining & Petrochemical: SIS loops, compressor/boiler protection, process interlocks

- Power Generation: turbine protection, balance-of-plant safeguards

- Chemicals & Pharma: critical utilities monitoring, reactor safety controls

A maintenance lead at a Gulf Coast refinery told us the AI3000-series analog inputs “seem to be the least fussy under electrical noise,” which matches what we typically see in brownfield upgrades with mixed legacy wiring.

Advantages & Value

- System compatibility – Drop-in fit for Triconex Tricon systems reduces engineering and qualification time.

- High availability – Designed for TMR safety architectures; minimizes spurious trips and improves uptime.

- Lifecycle cost savings – In many cases, replacing like-for-like modules avoids revalidation of safety logic and field terminations.

- Proven diagnostics – Built-in self-test and status LEDs speed troubleshooting, lowering mean time to repair.

- Technical support – Guidance on module selection, termination assemblies, and commissioning best practices.

Installation & Maintenance

- Cabinet & environment – Install in a Triconex chassis within a clean, ventilated cabinet; keep ambient within 0–60°C and avoid condensation.

- Grounding & wiring – Use shielded, twisted-pair for analog loops; ground shields at one end; route away from high-voltage and VFD cables.

- Hot-swap protocol – Follow Triconex procedures for removing/inserting modules in powered systems; check keying and slot assignment.

- Commissioning – Verify channel scaling and ranges in TriStation 1131; perform loop checks and note as-found/as-left values.

- Routine maintenance – Periodic inspection of terminal tightness, connector wear, and cleanliness; review diagnostics; firmware updates when approved by site MOC.

- Calibration practices – Where applicable, validate signal accuracy with traceable test equipment at site-defined intervals.

Quality & Certifications

- Typically compliant with CE and UL when used within the Triconex system

- SIL3-capable at the system level when engineered as part of a certified Triconex SIS

- RoHS applicability varies by revision; many units meet corporate environmental standards

- Manufacturer warranty practices apply; our supplied units are covered by a 365-day warranty

If you’re replacing an installed AI3351, sharing the current chassis type, slot position, and termination assembly part numbers typically speeds confirmation. One thing I appreciate is how straightforward the changeover can be when documentation is tidy—it often turns a weekend outage task into a short maintenance window.

Reviews

There are no reviews yet.