Description

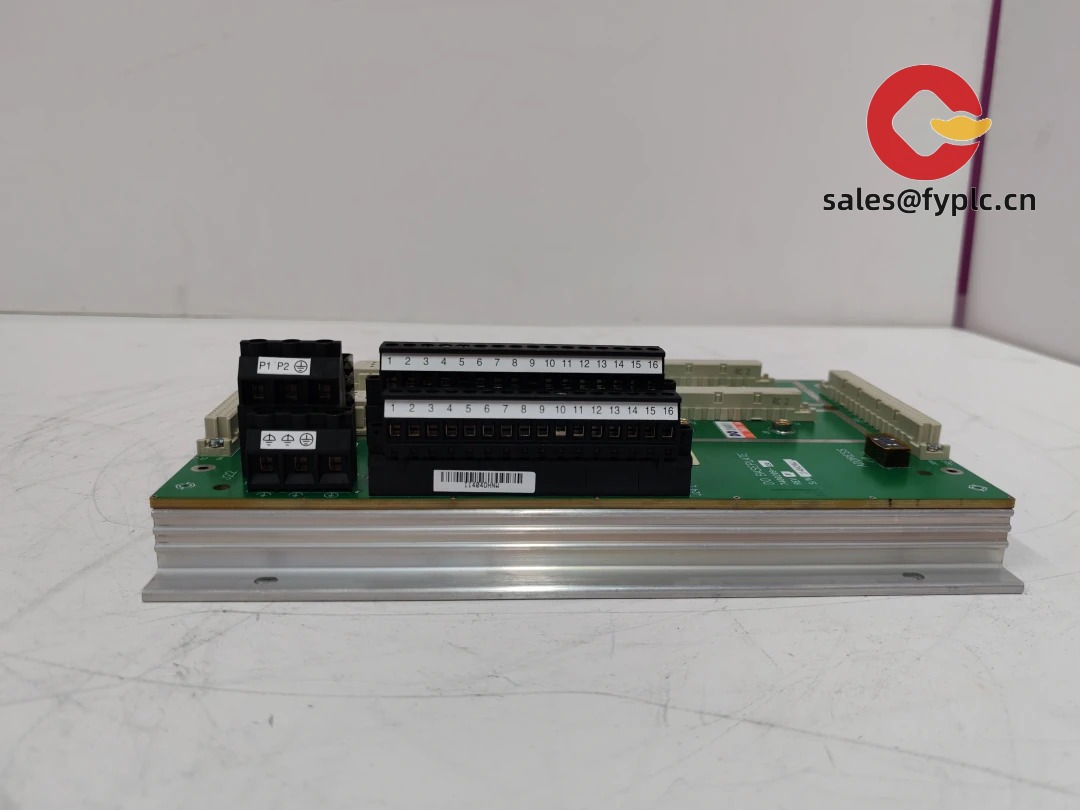

TRICONEX DO2401 (P/N 7400209-030) – Digital Output Module for Tricon Safety Systems

The TRICONEX DO2401 is a discrete output module designed for the Triconex Tricon safety PLC platform, typically used to drive field actuators, solenoids, and interposing relays in SIL-rated Emergency Shutdown (ESD), Fire & Gas, and Burner Management applications. From my experience, the DO2401 slots straight into a Tricon I/O chassis and delivers the high-availability behavior you’d expect from a TMR safety system—diagnostics, fault tolerance, and predictable switching of 24 Vdc field circuits in most cases. You might notice that it pairs well with standard field termination assemblies, keeping wiring tidy and maintenance straightforward.

Company’s Order Placement Process and Guarantees

- Warranty: 365 days

- Delivery time: 1 week for in-stock; no more than one month at the latest

- Payment: 50% advance payment; full payment for delivery

- Express delivery: FedEx, UPS, DHL

- Each unit is function-checked before shipment and packed for industrial transit

Key Features

- Digital (discrete) outputs – Built for switching typical 24 Vdc field loads such as solenoids and relay coils.

- High-density channel count – Multi-channel design (commonly 32 points), helping reduce cabinet footprint.

- TMR fault tolerance – Works within the Triconex triplicated architecture with per-point diagnostics and voting to maintain availability.

- Backplane integration – No external comms on the front; the module communicates over the Tricon backplane for configuration and health monitoring.

- Online replacement (when conditions allow) – In many cases, modules can be replaced with the system online when the chassis is healthy and remains triplicated.

- TriStation 1131 project compatibility – Parameters and channel usage are configured via standard Triconex tools.

- Field termination flexibility – Supports local or remote field termination assemblies to suit your panel layout.

Technical Specifications

| Brand / Model | TRICONEX DO2401, P/N 7400209-030 |

| System Compatibility | Triconex Tricon safety system I/O chassis (module plugs into Tricon backplane) |

| HS Code | 8537.10 (Boards/panels for electric control, ≤1000 V; final classification may vary by jurisdiction) |

| Power Requirements | Supplied via Tricon backplane; field circuits powered externally (typically 24 Vdc, per application and FTA) |

| Signal Output Type | Discrete digital outputs; commonly used for 24 Vdc loads; exact load/drive ratings depend on module revision and termination assembly |

| Channel Density | Multi-channel design (often 32 points); confirm against your BOM |

| Communication Interfaces | Proprietary Tricon backplane; no front-port external communications |

| Operating Temperature | Typically 0 to 60°C (32 to 140°F), non-condensing; follow cabinet derating guidelines |

| Installation Method | Plug-in module for Tricon chassis; wiring via local/remote field termination assembly (FTA) and I/O cables |

| Dimensions & Weight | Standard Tricon I/O card form factor; approx. 350 × 40 × 230 mm; ~0.9 kg (typical) |

| Safety Integrity Context | Used within Tricon SIL3 TMR architectures; system-level certification applies |

Application Fields

The DO2401 shows up most in safety-critical outputs where deterministic switching and diagnostics matter:

- Oil & Gas ESD/HIPPS – Driving shutdown valves, blowdown solenoids, and relay interlocks.

- Refining & Petrochem – Unit trip logic, pump permissives, and motor contactor control.

- Power Generation – Turbine trip solenoids, fuel isolation, turning gear interlocks.

- Chemical & Pharma – Safe state outputs for batch isolation and utility cut-off.

- Marine & LNG – Boiler/BMS outputs, fire dampers, and ESD tie-ins.

A maintenance lead told us the module “behaves predictably under proof-test, and diagnostics flag channel issues before they become plant issues,” which, frankly, lines up with what we see in most installations.

Advantages & Value

- Reliability in TMR systems – Built for continuous operation with diagnostic coverage that suits SIL-level proof-testing regimes.

- Compatibility – Fits standard Tricon chassis and works with TriStation 1131 projects, easing drop-in replacement during turnarounds.

- Cost control – High-density channels can reduce cabinet space and auxiliary relays; fewer panels usually mean lower lifecycle cost.

- Service support – Clear status LEDs and system diagnostics shorten troubleshooting time in many cases.

Installation & Maintenance

- Cabinet & environment – Install in a clean, dry control cabinet with adequate ventilation; keep within 0–60°C and avoid corrosive atmospheres.

- Wiring – Use the designated FTA and cable set; size conductors for load current and fusing; label channels for proof-test efficiency.

- Field power – Provide stable 24 Vdc (typical) for loads; observe polarity and any line monitoring requirements defined in your design.

- Safety – De-energize the affected circuits before handling wiring. Module online replacement is possible in many cases, but follow Triconex procedures and MOC rules.

- Routine care – Periodically inspect terminal tightness, clean dust with dry air, and execute scheduled SIS proof-tests. Keep firmware and project documentation aligned with change control.

- Spares strategy – Maintain at least one spare module per installed type for critical units to keep MTTR low.

Related Components (for a complete build)

- Tricon I/O Chassis & Power Supplies – Houses the DO2401 and provides backplane power and communications.

- Field Termination Assembly (FTA) – Breaks out module channels to terminal blocks; choose type to match load and monitoring scheme.

- I/O Cables – Shielded interconnects between module and FTA; keep lengths within recommended limits.

- Interposing Relays (if needed) – For higher current or different voltage classes, interpose relays/contactors as specified by the design.

Quality & Certifications

- Designed for use in IEC 61508 SIL3 Tricon systems (system-level certification applies)

- CE marking and regional approvals are commonly available for the Tricon platform

- Manufacturer quality system typically ISO 9001

- RoHS/UL/CSA availability may vary by revision and region—share your compliance list and we will verify against your exact P/N 7400209-030

Note: Load ratings and channel count can vary by module revision and FTA pairing. If you share your current Tricon hardware list, we’ll confirm the exact output type, point count, and allowable load per channel for DO2401 7400209-030.

Reviews

There are no reviews yet.