Description

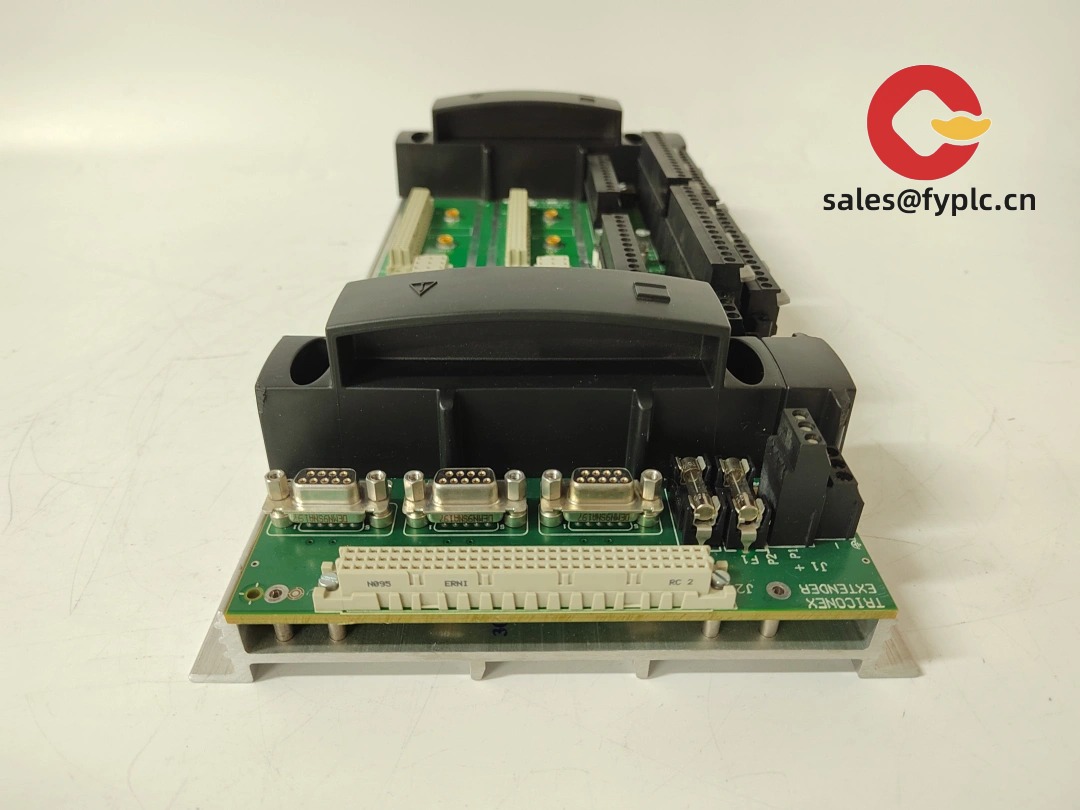

TRICONEX EPI3382 – Expander Interface Module for Tricon TMR Systems

The TRICONEX EPI3382 is an expander interface module designed to extend the capacity of Triconex TMR safety systems by linking the main processor chassis to expander/remote I/O chassis. From my experience, this module is selected when operators need to scale I/O counts or distribute I/O racks while maintaining deterministic communications and system-level diagnostics. You might notice that it drops straight into a Tricon chassis slot and is powered from the backplane—no external PSU headache.

Company’s Order Placement Process and Guarantees

- Warranty: 365 days

- Delivery: 1 week if in stock; no more than one month at the latest

- Payment: 50% advance payment; full payment before delivery

- Express: FedEx, UPS, DHL

Key Features

- Expander chassis interface: Connects Tricon main processors to expander/remote I/O racks for scalable capacity.

- Deterministic, high-reliability link: Purpose-built for safety applications where predictable latency matters.

- Backplane powered: Draws power from the Tricon chassis; typically no external supply required.

- Integrated diagnostics: Works with TriStation to report status, link health, and module faults.

- SIL3 system alignment: Designed for use within Triconex SIL3-certified architectures (system-level).

- Single-slot form factor: Fits standard Triconex racks with keyed positions to avoid mis-insertion.

- Lifecycle-friendly: In many cases supports controlled online replacement under site procedures.

Technical Specifications

| Brand / Model | TRICONEX EPI3382 |

| HS Code | 8538.90 (Parts suitable for apparatus of 8535/8536/8537) |

| Power Requirements | Backplane-powered from Tricon chassis; no external power input |

| Operating Temperature | Typically 0 to 60 °C, 5–95% RH non-condensing (depends on module revision) |

| Signal I/O Types | Proprietary expander link for remote/expander chassis; Tricon backplane interface |

| Communication Interfaces | Expander interface ports (module-to-expander chassis), Tricon backplane bus |

| Installation Method | Single-slot, plug-in module for Tricon main/expander racks; keyed position; secured with front latch |

| Dimensions & Weight | Single-slot Triconex card; typical shipping weight under 1 kg |

Application Fields

The EPI3382 is deployed where a Tricon safety controller needs to scale out reliably:

- Emergency Shutdown (ESD) and Fire & Gas systems requiring large or distributed I/O

- Burner Management Systems (BMS) with segregated field cabinets

- HIPPS and pipeline protection where remote I/O racks are closer to process skids

- Compressor/turbomachinery protection with dedicated expander racks per train

- Refining, petrochemical, and upstream platforms needing deterministic rack-to-rack links

A maintenance lead from a Middle East refinery summed it up well: “We added two expander racks on a turnaround, and the EPI modules came up clean—no surprises. Diagnostics in TriStation made loop checks faster than we expected.”

Advantages & Value

- Native compatibility: Seamless fit with existing Triconex platforms—saves engineering time and avoids protocol gateways.

- Reliability for SIL3 systems: Designed for safety-critical deployments with robust diagnostics and predictable behavior.

- Total cost control: Extends capacity without replacing controllers; typically shortens outage windows.

- Lifecycle support: Firmware and revision management through TriStation, plus straightforward spares strategy.

Installation & Maintenance

- Environment: Install in a Tricon-certified enclosure or cabinet with adequate ventilation; keep within the stated temperature range.

- Wiring: Use vendor-approved expander link cables; maintain proper shielding and grounding to minimize noise.

- Safety: Follow site MOC and LOTO. Place the controller in the appropriate mode before inserting or removing modules; observe ESD precautions.

- Commissioning: Verify firmware compatibility in TriStation, check link status LEDs/diagnostics, and document rack addressing.

- Routine care: Periodic visual inspection, dust removal with dry air, and configuration backup. Plan firmware updates during scheduled outages.

Quality & Certifications

- Certifications: Typically CE and cULus; system-level SIL3 compliance per IEC 61508 when applied within the Triconex architecture (exact markings depend on revision).

- Manufacturing quality: Built for industrial environments with conformal coating and rigorous factory testing.

- Warranty: 365-day warranty support as stated above.

Related Components (for planning and compatibility)

- TRICONEX 3008 Main Processor – core TMR CPU used with expander interfaces

- TRICONEX 4351 TCM – Tricon Communication Module for external DCS/SCADA connectivity

- TRICONEX 3721 / 3700A I/O – common DI/DO modules typically installed in expander racks

- TRICONEX Power Supply Modules – redundant PSU options sized per rack and I/O load

If you’re matching an existing system, sharing the controller type, chassis size, and current firmware revisions usually saves time. One thing I appreciate is how predictable the EPI3382 behaves across revisions, but it’s still best practice to align firmware during a planned outage.

Reviews

There are no reviews yet.