Description

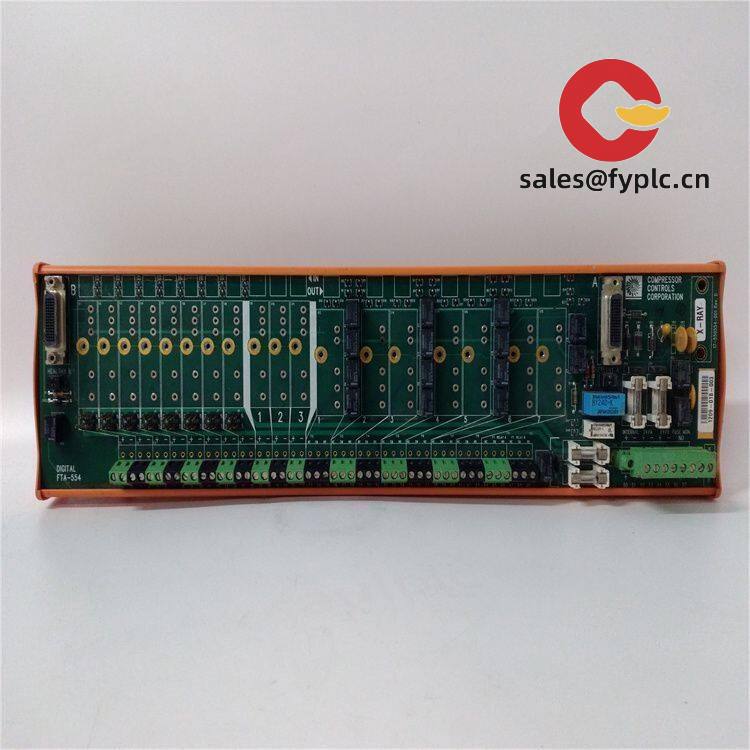

TRICONEX FTA-554-17 (550554-001) – Field Terminal Assembly for Safe, Clean I/O Wiring in Triconex SIS

The TRICONEX FTA-554-17, part number 550554-001, is a Field Terminal Assembly designed to make wiring to Triconex safety I/O straightforward and serviceable. From my experience, this type of FTA is typically used to land multiple field circuits in one place, protect the cabinet layout, and simplify future maintenance. You might notice that projects with FTAs like this usually commission faster because channel labeling, segregation, and test access are much cleaner than raw cable tails.

Company’s Order Placement Process and Guarantees

- Warranty: 365 days

- Lead time: 1 week if in stock; no more than one month at the latest

- Payment terms: 50% advance payment, full payment before delivery

- Express delivery: FedEx, UPS, DHL

Key Features

- Purpose-built FTA for Triconex I/O – Provides a reliable termination point between field devices and Triconex safety modules, reducing wiring errors.

- Clean, service-friendly layout – Channel grouping and clear labeling help technicians trace signals quickly during FAT/SAT and maintenance.

- Discrete signal handling – Typically used for 24 VDC digital inputs or outputs (depending on the paired I/O card), keeping signal integrity stable over time.

- Passive termination design – In many cases, no separate power supply is required; the assembly interfaces directly with the I/O module via the dedicated cable.

- Cabinet-friendly installation – Suitable for DIN-rail or panel mounting, which makes retrofits and expansions straightforward.

- Industrial-grade durability – Built for control cabinets in harsh process environments with appropriate surge/shielding practices when installed correctly.

Technical Specifications

| Parameter | Details |

|---|---|

| Brand / Model | TRICONEX FTA-554-17 (P/N 550554-001) |

| Product Type | Field Terminal Assembly (FTA) for Triconex safety I/O |

| HS Code | 8538.90 (Parts suitable for apparatus of 8535–8537) |

| Signal Input/Output Types | Discrete field signals (commonly 24 VDC DI/DO, depending on matched I/O module) |

| Power Requirements | Passive termination; no external power required for basic operation |

| Communication/Connection Interface | Dedicated Triconex I/O cable harness between FTA and I/O module; screw/clamp terminals for field wiring |

| Operating Temperature | 0 to 60°C, 5–95% RH non-condensing (typical cabinet conditions) |

| Installation Method | DIN-rail or panel (backplate) mounting in a protected control cabinet |

Application Fields

In safety instrumented systems, FTAs like the FTA-554-17 are commonly used at the marshalling layer to connect field devices to Triconex I/O cards. Typical use cases include:

- ESD/PSD systems in oil & gas (wellhead shutdowns, process trips, valve end switches)

- Boiler/BMS and burner management interlocks in power & utilities

- Chemical/petrochemical emergency interlocks and annunciation

- Turbomachinery protection signals (overspeed contacts, permissives) via discrete channels

- Pipeline stations, tank farms, and terminals for simple on/off field contacts

One thing I appreciate is how these assemblies reduce panel depth and keep channel segregation clean, especially when you’ve got mixed-voltage loops or need to separate critical trips from non-critical statuses.

Advantages & Value

- Reliability – Robust terminations reduce loose connection faults and intermittent trips that are hard to trace.

- Compatibility – Designed for Triconex SIS I/O, which means fewer surprises during commissioning and loop checks.

- Cost Savings – Shorter installation time and faster troubleshooting typically translate to lower labor hours across the project lifecycle.

- Lifecycle Support – Widely used in brownfield upgrades; seems to be a practical choice when replacing aging termination strips without reworking the entire cabinet.

A maintenance lead at a gas processing plant told me they shaved a day off their SAT because the FTA labeling and grouped test points made it easy to prove all trips and permissives in one go.

Installation & Maintenance

- Cabinet standards – Mount in a clean, ventilated cabinet with proper earthing; maintain clearance for cable bend radius and service access.

- Wiring – Use correctly rated ferrules; tighten to the manufacturer’s torque; segregate high-voltage and low-level signals; keep shield drains bonded at a single point to minimize noise.

- Grounding/shielding – Route I/O cable shields to cabinet ground as per site EMC rules; avoid ground loops across marshalling areas.

- Safety – De-energize circuits before touching terminals; verify isolation of field loops and tag-out/lock-out in place.

- Routine checks – Re-torque terminals during scheduled outages; inspect for discoloration, corrosion, or insulation nicks; clean dust with dry air to preserve insulation resistance.

- Documentation – Keep updated channel lists and loop drawings at the panel; it typically reduces fault-finding time dramatically.

Quality & Certifications

- Compliance – CE and RoHS applicable for component-level hardware used in control cabinets.

- SIS context – Commonly deployed within SIL-rated Triconex systems; system-level SIL certification applies when installed with certified modules and per safety lifecycle practices.

- Warranty – 365-day warranty from shipment.

If you’re matching this FTA to existing Triconex I/O, share the I/O card type and cable part number and I’ll double-check compatibility and channel mapping before you place the order. It usually prevents small but costly wiring rework on site.

Reviews

There are no reviews yet.