Description

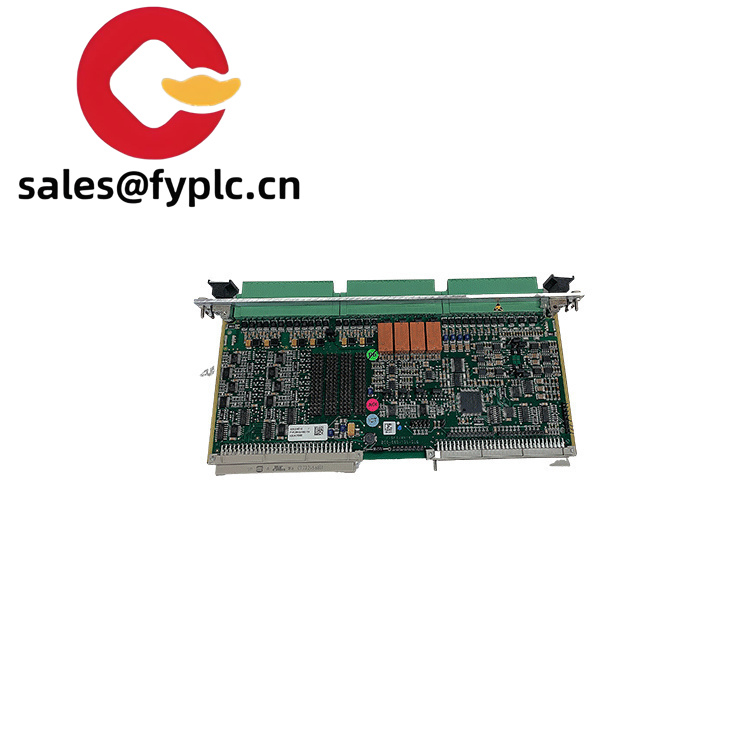

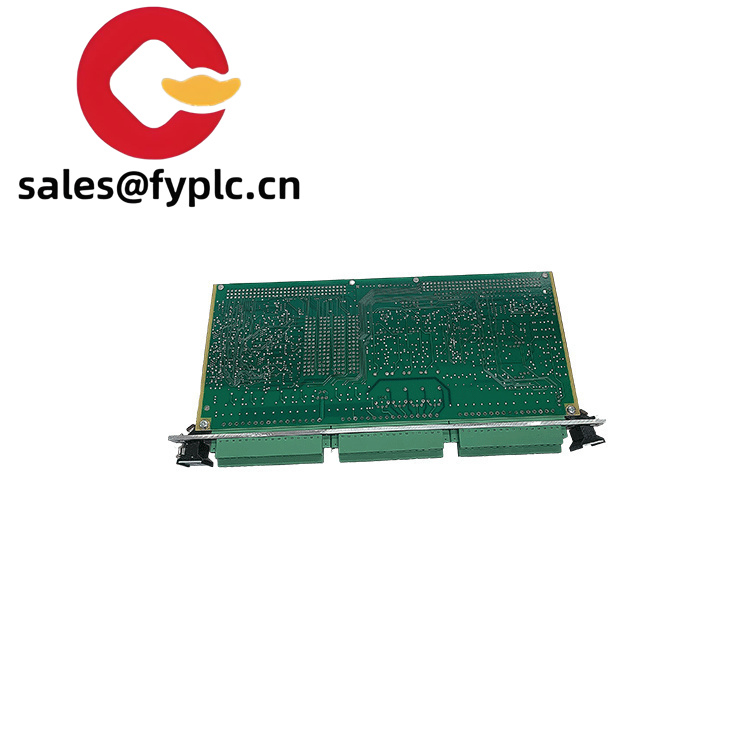

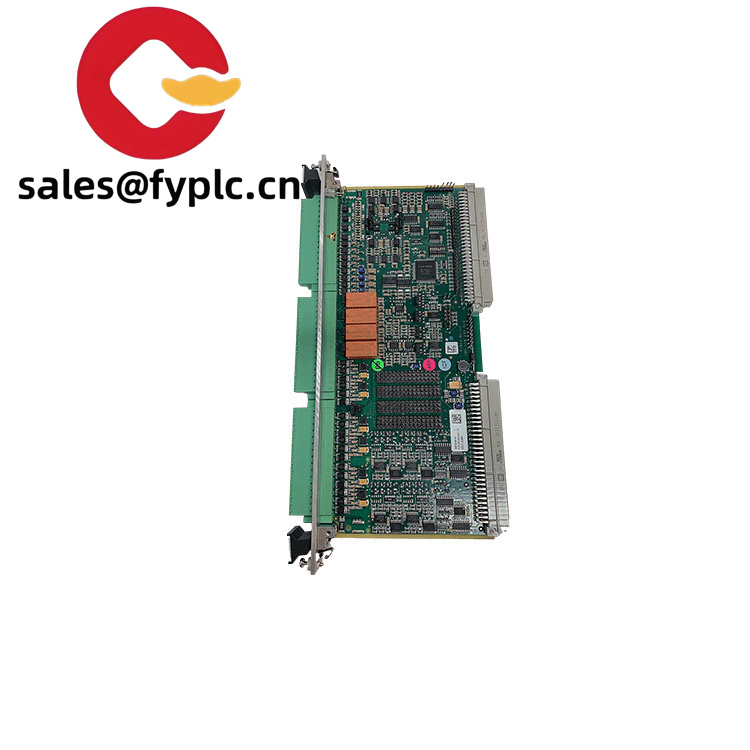

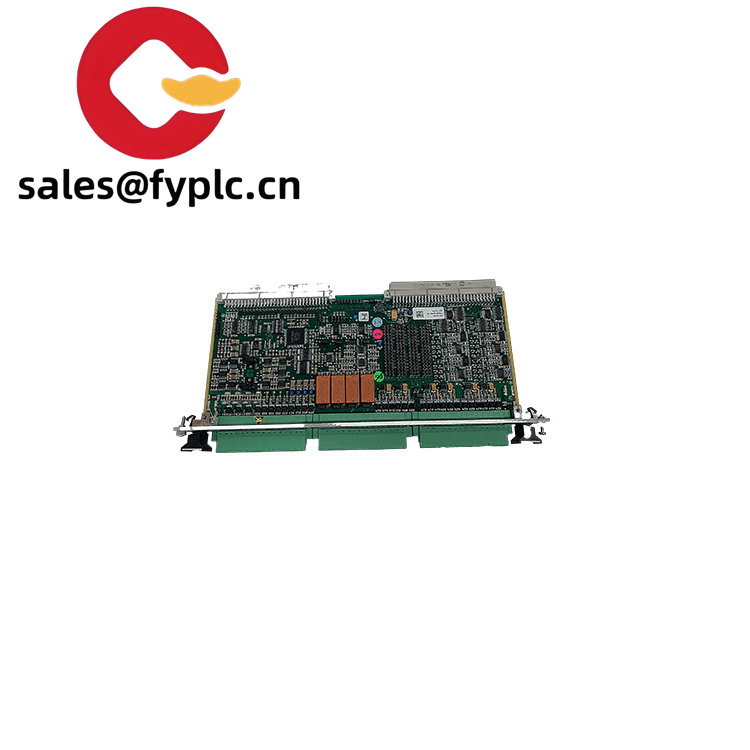

Vibro-meter-VM600 200-560-000-114 200-560-101-018 IOC4T mechanical card power module

Components 200 – 560 – 000 – 114 and 200 – 560 – 101 – 018 are likely specific accessory or connector codes associated with the IOC4T input/output module. These accessories play a vital role in aspects such as module power connection, signal transfer, or integration with other systems. Their proper functioning ensures the stable operation of the entire system and the accurate transmission of data.

| Label | Specification |

|---|---|

| Model Number | VM600 (with components 200 – 560 – 000 – 114, 200 – 560 – 101 – 018 and IOC4T module) |

| Brand | Vibro – meter |

| Type | Vibration monitoring and analysis system |

| Input Channels of IOC4T | Multiple input channels to connect various sensors like accelerometers, proximity probes, etc. |

| Output Channels of IOC4T | Capable of outputting processed data to display devices or control systems, with options such as analog outputs (e.g., 0 – 10V or 4 – 20 mA) for continuous data representation and relay outputs for discrete control signals |

| Signal Processing in IOC4T | Built – in signal conditioning functions including filtering (to remove noise and unwanted frequencies) and amplification (to boost weak signals for better processing) |

| Communication Interfaces | Supports standard industrial communication protocols such as Ethernet for high – speed data transfer over a network, and may also be compatible with serial communication protocols like RS – 232 or RS – 485 for connection with legacy or more specialized devices. This allows for seamless integration with other components in the industrial control ecosystem |

| Operating Temp | Designed to operate within a wide temperature range, typically – 10 °C to 60 °C. This makes it suitable for deployment in various industrial environments, from cold storage facilities to hot processing plants |

| Protection Class | Offers a high – level of protection against environmental factors. For example, it may have an IP rating such as IP65, which protects against dust ingress and water jets from any direction, ensuring reliable operation even in harsh industrial settings |

| Dimensions | Compact design to fit into industrial control cabinets. The IOC4T module, for instance, might have dimensions like 100mm x 50 mm x 30mm, optimizing space utilization while maintaining functionality |

| Power Supply | Operates on a stable DC power supply, such as 24V DC. This provides a reliable power source for the module to perform its functions without fluctuations that could affect data accuracy or system stability |

| Compatibility | Highly compatible with other components within the VM600 series, as well as with a wide range of third – party sensors and control systems. This flexibility allows for easy customization and expansion of the overall vibration monitoring system |

| Programmability | The IOC4T module can be programmed to suit specific industrial requirements. Users can configure parameters such as input/output mapping, signal processing algorithms, and alarm thresholds according to the unique characteristics of their equipment and production processes |

Reviews

There are no reviews yet.