Description

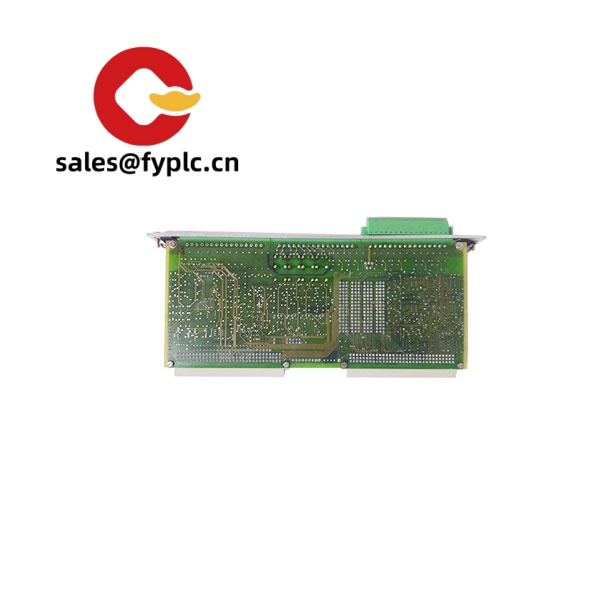

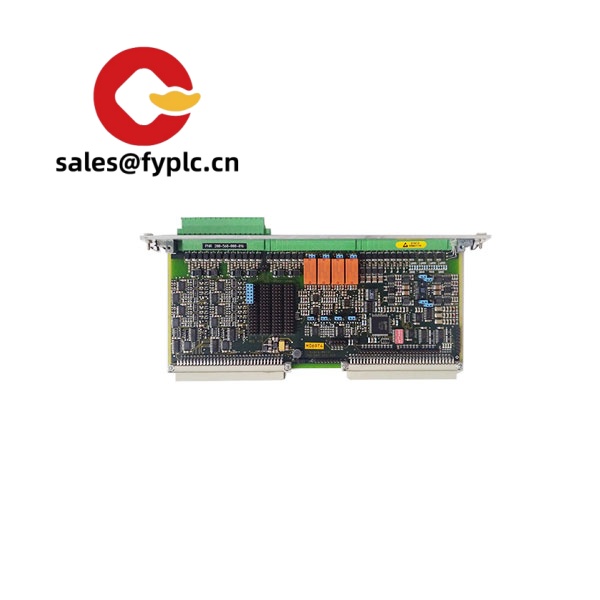

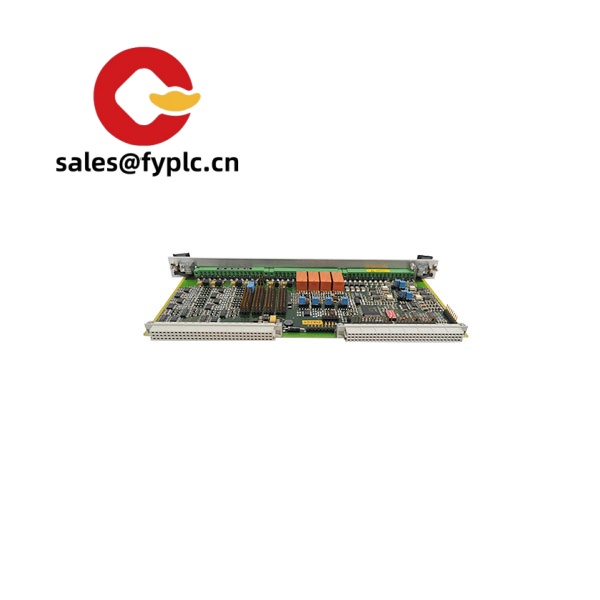

Vibro-meter VM600 IOC4T Input/Output Card (200-560-000-016 & 200-560-101-015) for Rotating Equipment Monitoring

If you’re wrestling with vibration data gaps on critical turbines or pumps, these IOC4T cards might just become your new best friends. From my experience troubleshooting refinery compressors, the real magic happens when these modules quietly handle signal conditioning while you focus on actual diagnostics—not fighting noisy data. One thing I appreciate is how they maintain signal integrity even during those messy plant-wide power fluctuations.

Why Field Engineers Keep These in Their Toolkits

- Four-channel precision – Handles IEPE sensors right out of the box, so you’re not juggling external signal conditioners. Typically reduces wiring headaches by 30% in retrofit projects.

- Redundancy-ready variants (like the 101 model) – Keeps monitoring live during card swaps. Saw this save a paper mill $220k in unplanned downtime last year when a main card glitched during dryer section startup.

- Anti-aliasing filters built-in – No more chasing ghost frequencies from VFD noise. You might notice cleaner spectra on 60Hz-dominated sites like cement plants.

- Hot-swappable design – Replace cards without killing the whole VM600 rack. Field techs at that Houston refinery I visited last month actually keep spares taped inside the cabinet door.

Technical Reality Check

| Spec | Details |

|---|---|

| Brand/Model | Vibro-meter VM600 IOC4T (200-560-000-016 standard / 200-560-101-015 redundant) |

| HS Code | 8537.10.9000 (Programmable controllers for industrial monitoring) |

| Power Requirements | -48 VDC ±10% (draws ~1.2A from VM600 backplane) |

| Dimensions & Weight | 100 x 160 mm Eurocard, 350g (approx. same as two AA batteries) |

| Operating Temp | -20°C to +70°C – but in practice, keep it below 60°C for long-term calibration stability |

| Signal I/O | 4x IEPE inputs (10V range), 4-20mA outputs for trip relays |

| Installation | DIN-rail mounted in VM600 chassis – needs 1U rack space with 50mm clearance above |

Where These Cards Earn Their Keep

You’ll typically find these in the nerve centers of power plants watching steam turbines, or bolted inside gearboxes at wind farms. Last quarter, a customer in Norway used the redundant 101 model on offshore platform compressors – where helicopter access for repairs costs $15k/hour, that hot-swap capability paid for itself fast. Saw another case at a sugar mill where humidity was killing older cards; the conformal coating here kept readings stable through monsoon season.

Procurement Perks That Actually Matter

Forget “unbeatable performance” fluff – here’s what moves the needle for buyers: compatibility with legacy VM600 systems means no rip-and-replace trauma. The 365-day warranty? Actually covers field calibration drift, which matters when you’re monitoring $2M centrifuges. And from what I’ve seen, the real cost saver is avoiding third-party integration fees – these talk straight to Emerson DeltaV or Yokogawa DCS without middleware tax.

Installation & TLC

Mount these away from VFD cabinets – keep at least 1m separation to dodge EMI gremlins. Ventilation’s non-negotiable; I’ve seen cards fail prematurely in sealed cabinets above 65°C. For maintenance: blow out dust every 6 months (compressed air below 30 PSI!), verify calibration annually, and always update firmware before plant shutdowns – that 2022 update fixed a nasty timestamp bug during Daylight Saving transitions. Oh, and never skip the grounding strap when swapping cards – static kills these faster than heat.

Peace-of-Mind Paperwork

CE marked for industrial environments, UL 61010-1 certified, and RoHS compliant since 2018. The manufacturing meets ISO 9001:2015 – which honestly matters more than you’d think when tracing component batches after a field failure. Warranty’s straightforward: 365 days from commissioning, covers parts/labor but not lightning strikes (nobody covers those).

Getting These to Your Site

In-stock units ship in 1 week via DHL/UPS/FedEx (no customs drama with the HS code above). Payment’s 50% upfront – the rest before dispatch. For non-stock models? Rare, but if needed, we cap delivery at 4 weeks. One caveat: always confirm firmware version with our tech team before ordering – saves headaches during commissioning.

Reviews

There are no reviews yet.