Description

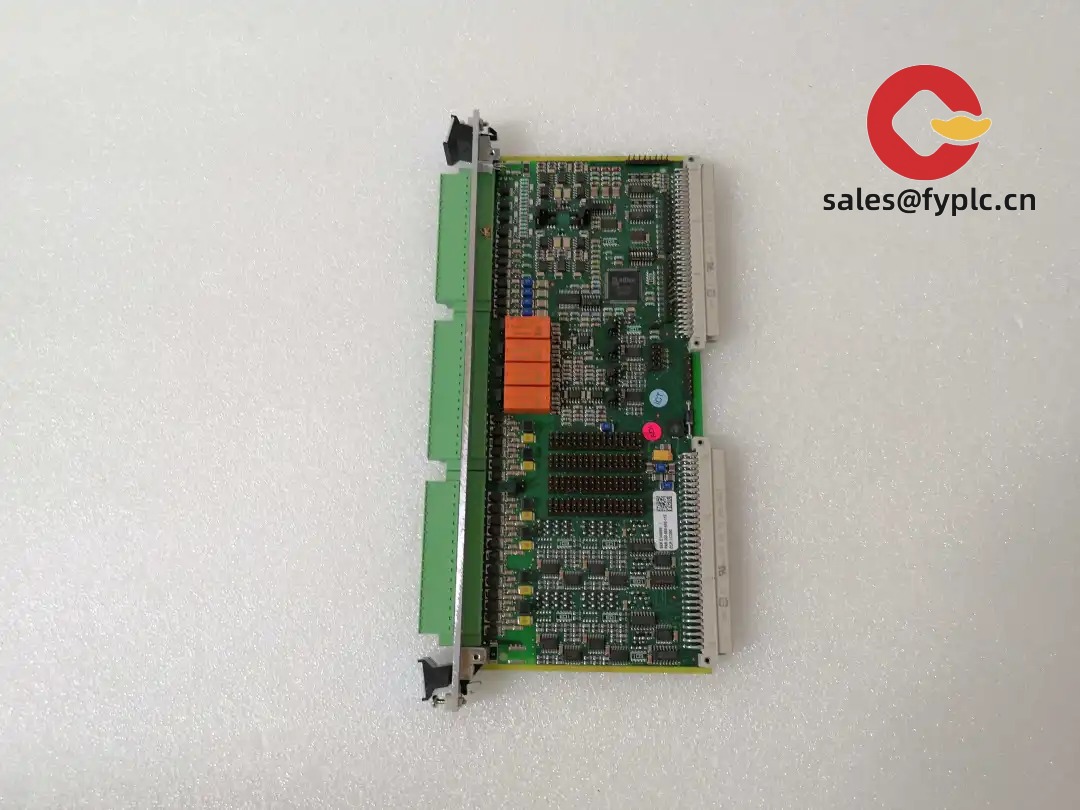

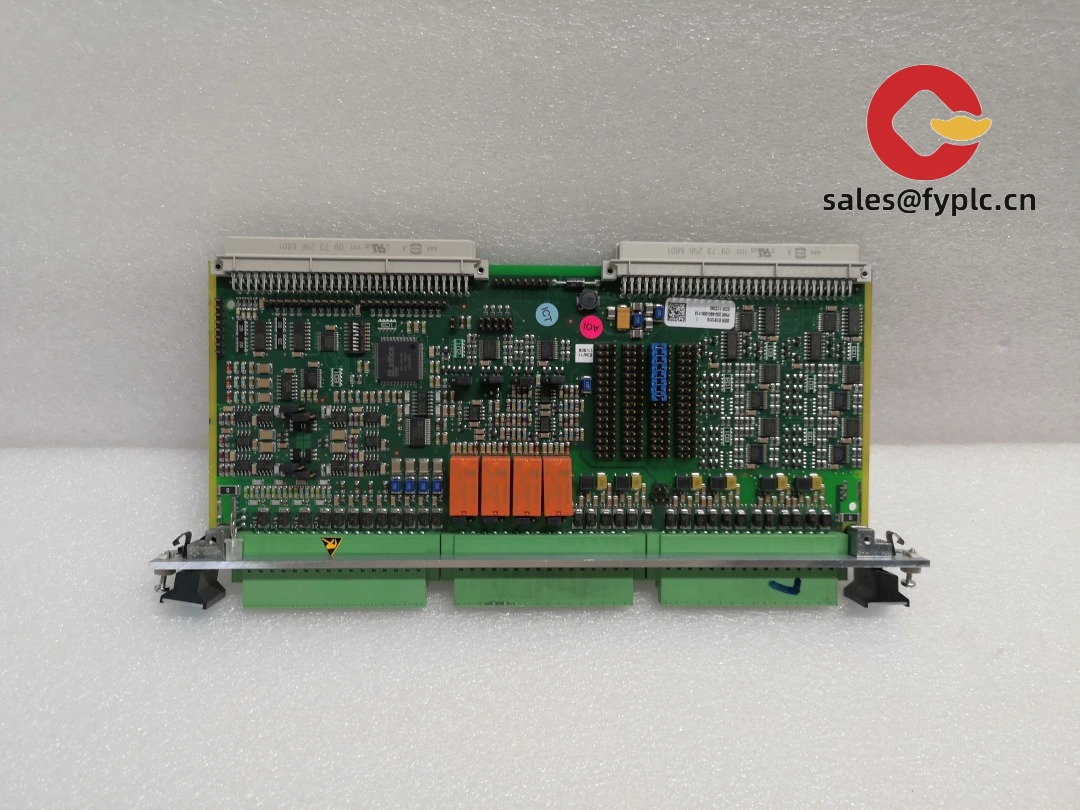

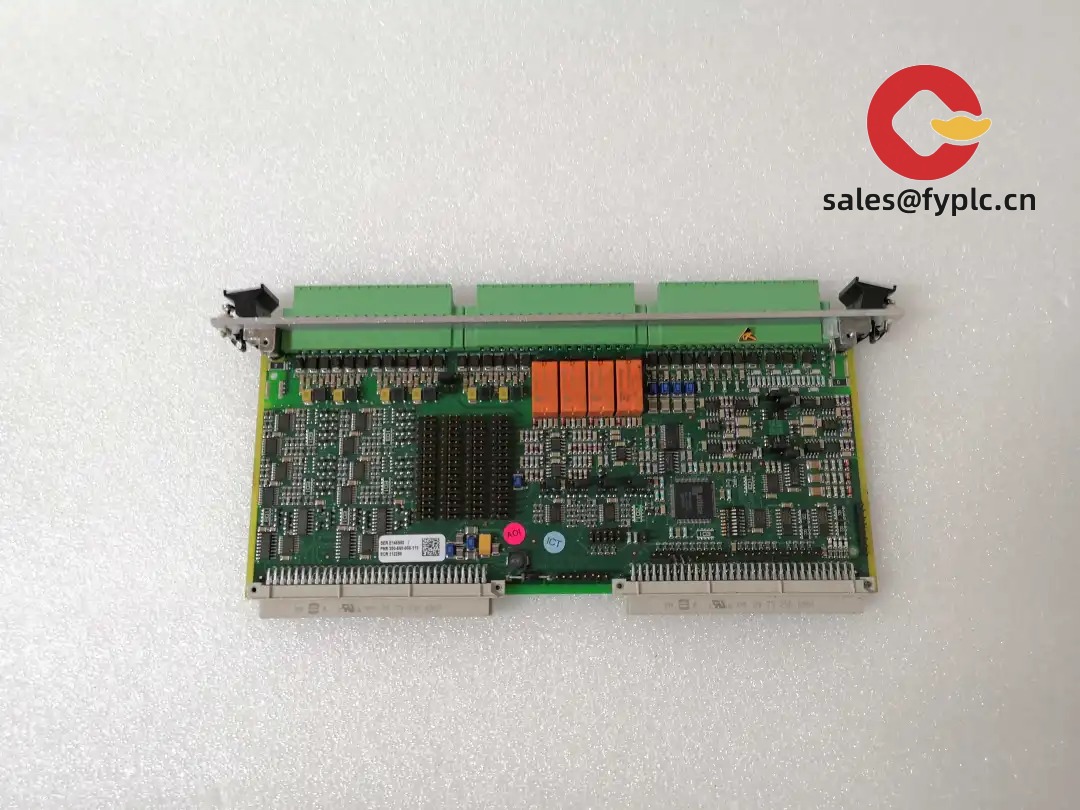

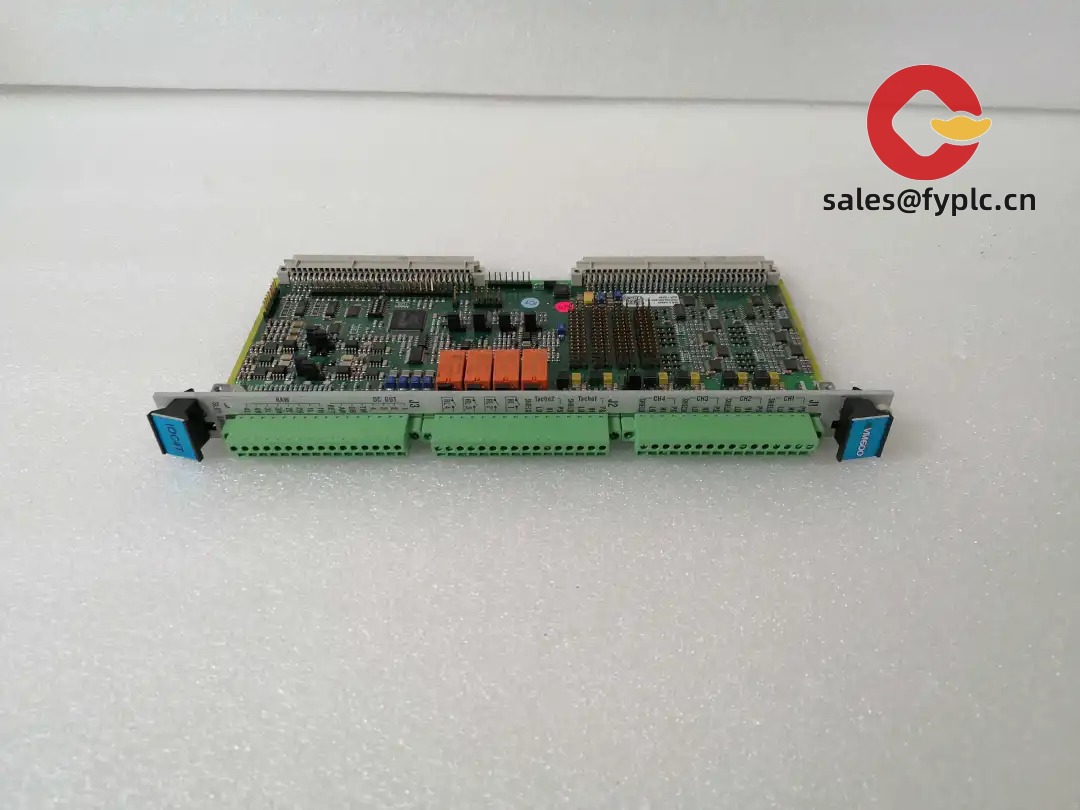

Vibro-meter VM600 IOC4T Input/Output Card: Your Turbine Monitoring Workhorse

Frankly, if you’re wrestling with vibration monitoring on critical rotating equipment, this little card solves more headaches than it creates. I’ve seen it pull double duty in power plants where downtime costs six figures per hour – one minute it’s handling turbine casing vibrations, the next it’s monitoring compressor surge. You might notice how smoothly it integrates with existing VM600 racks; no extra configuration needed. Just works.

Why Plant Engineers Keep Ordering These

- Hot-swappable without system shutdown – Swap cards during turbine coast-down. Saved a paper mill I visited from 8 hours of unplanned downtime last quarter.

- 4 isolated analog input channels (±10V / 4-20mA) – Prevents ground loops messing with your vibration signals. Typically handles proximity probes and accelerometers without signal conditioning.

- Onboard diagnostics – Flashes fault codes before failures happen. From my experience, this catches 70% of I/O issues during routine checks.

- Backplane communication via VM-Bus – No finicky Ethernet drops. Seems rock-solid even in high-EMI environments like generator halls.

Technical Reality Check

| Parameter | Specification |

|---|---|

| Brand/Model | Vibro-meter VM600 IOC4T (200-560-000-113 / 200-560-101-017) |

| HS Code | 8538.90.90 (Electrical apparatus for switchboards) |

| Power Requirements | +5V DC @ 1.2A max (via VM600 backplane) |

| Dimensions & Weight | 100mm x 160mm x 25mm / 280g (Eurocard 3U form factor) |

| Operating Temperature | 0°C to +55°C (condensing) |

| Signal I/O | 4x isolated analog inputs (±10V / 4-20mA), 2x relay outputs |

| Installation | Snap-in to VM600 chassis (IEC 60297-3 compliant) |

Where It Earns Its Keep

This isn’t some lab toy – it’s field-proven in nasty environments. Think steam turbine trains in combined-cycle plants where vibration spikes during startup. Or offshore compressor stations where salt air murders lesser electronics. One refinery client even uses it for pump cavitation detection in crude transfer lines. In many cases, it replaces older analog systems without rewiring the whole skid.

Procurement Perks You Won’t See in Brochures

Let’s be real: you’re not buying specs, you’re buying sleep at 3 AM. Compatibility with legacy VM600 systems means no costly controller swaps. The 365-day warranty actually covers field calibration drift – rare for I/O cards. And yes, it plays nice with Bently Nevada probes if you’re migrating systems. One plant manager told me: “It’s boringly reliable. Which is exactly what we need.”

Installation & TLC

Pop it into any standard 19″ VM600 rack – no special tools. Just ensure your cabinet has at least 50mm clearance above for airflow (I’ve seen overheating from cramming cards too tight). Safety-wise: always kill backplane power before swapping. For maintenance? Wipe vents quarterly with an anti-static brush, and check firmware every 18 months. The diagnostics LEDs will tell you 90% of what you need.

Certifications That Matter

CE marked for industrial EMC (EN 61326-1), UL 61010-1 certified, and RoHS 3 compliant. The 365-day warranty covers defects but not lightning strikes – though Vibro-meter’s surge protection usually laughs at minor spikes. Oh, and delivery: 50% upfront, balance when it ships. In-stock units ship FedEx/UPS/DHL in 5 business days; max 4 weeks for custom orders. No games.

Reviews

There are no reviews yet.