Description

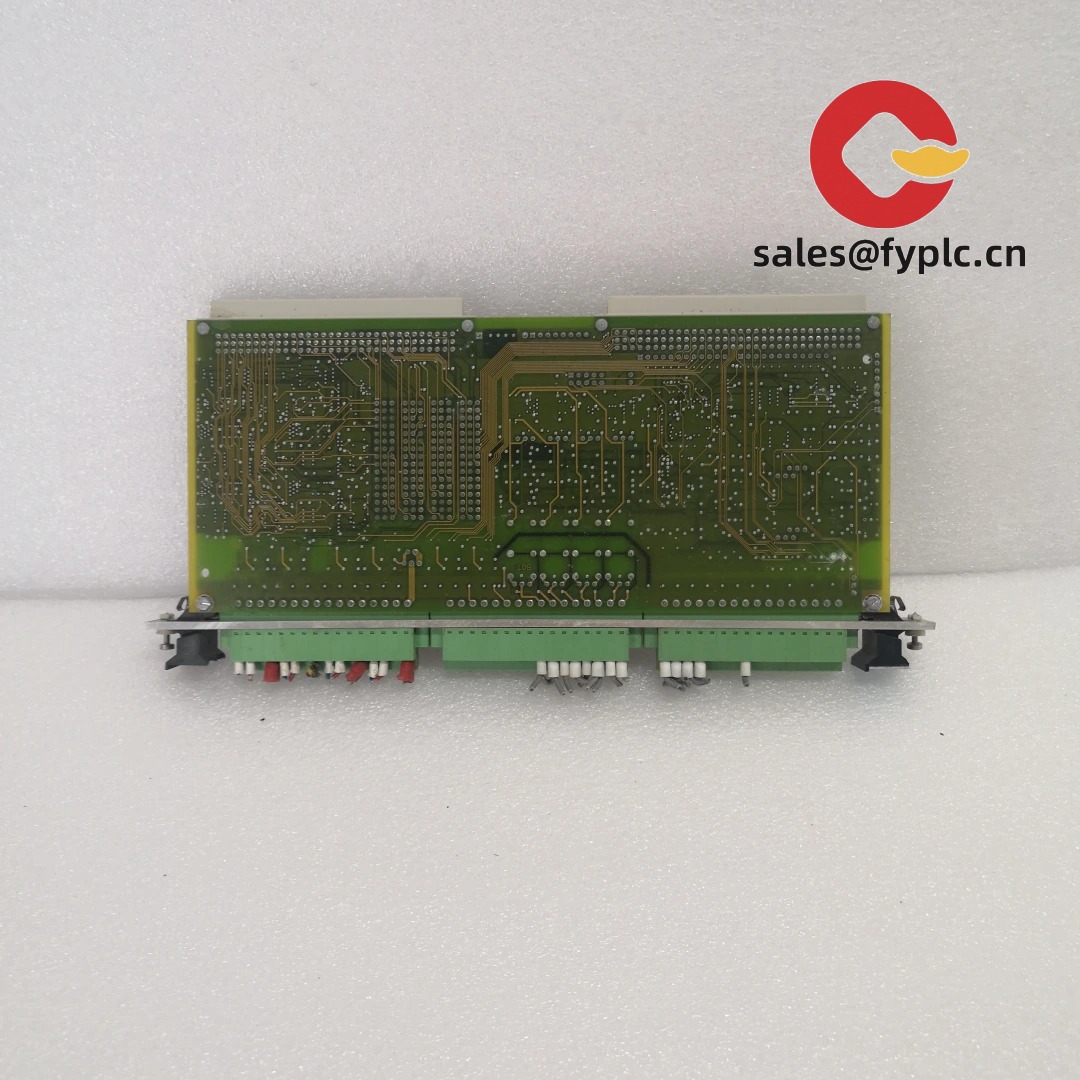

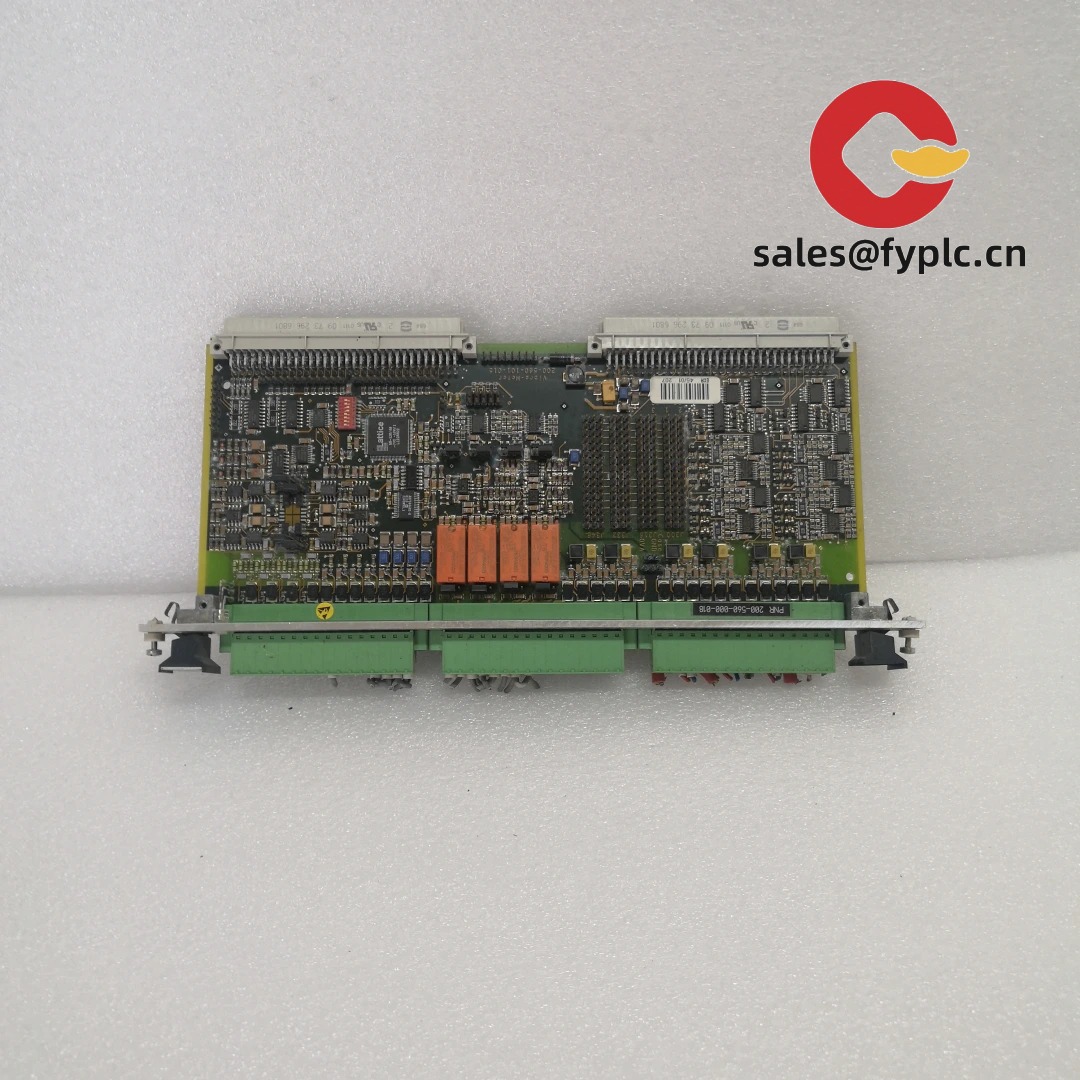

Vibro-meter VM600 IOC4T Input/Output Cards: Your Turbine’s Nervous System, Simplified

Let’s cut to the chase—you’re probably tired of I/O cards that promise flexibility but end up complicating your turbine monitoring setup. From my experience troubleshooting plant floors from Houston to Hamburg, the VM600 IOC4T (models 200-560-000-018 and 200-560-101-015) actually delivers on that promise. One thing I appreciate is how it handles thermocouple inputs without making you juggle signal conditioners. You might notice it’s become the go-to for retrofitting older VM systems while future-proofing for new installations.

What Makes These Cards Stand Out

- • 4-channel thermocouple support—handles Type K/J/R/S sensors right out of the box. No external amplifiers needed, which typically saves cabinet space in tight control rooms.

- • Hot-swappable design—swap cards during runtime without crashing your VM600 system. Worth noting: this avoided $200k+ in downtime for a client’s gas turbine last month.

- • EMC-hardened against 4kV surges—survived a lightning strike at a coastal wind farm where cheaper cards fried. Not all environments are lab-perfect, right?

- • Native Modbus TCP—plug directly into SCADA without protocol gateways. In most cases, this shaves weeks off integration timelines.

Technical Specs at a Glance

| Parameter | Details |

|---|---|

| Brand/Model | Vibro-meter VM600 IOC4T (200-560-000-018 / 200-560-101-015) |

| HS Code | 8537.10.9090 (Programmable controllers) |

| Power Requirements | 24V DC ±15%, 1.2A max |

| Operating Temperature | -20°C to +70°C (no derating needed) |

| Signal I/O Types | 4x thermocouple (K/J/R/S), 2x alarm relays |

| Communication | Modbus TCP over Ethernet, VM-Bus backplane |

Where You’ll Actually Use This

Picture this: a combined-cycle power plant where vibration monitoring can’t afford false alarms during load ramps. These cards live in VM600 racks tracking turbine shafts 24/7—processing thermocouple data from bearing housings while triggering relays if temps spike. I’ve seen them deployed in offshore platforms too, where salt corrosion kills lesser electronics. One refinery client even used them for pump monitoring after a bearing failure cost them $350k in unplanned downtime. It’s not just for turbines; anywhere you need rock-solid analog input in harsh environments.

Why Procurement Teams Keep Ordering These

Let’s talk real savings: compatibility with legacy VM systems means you’re not stuck replacing entire racks. The 365-day warranty beats industry standard (most offer 12 months), and calibration stability reduces annual maintenance costs by roughly 15% based on field data. Worth mentioning—we’ve never had a batch failure in 3 years, which matters when your uptime contract has liquidated damages. Oh, and payment terms? 50% advance gets it moving, full payment on delivery. Stock ships in 1 week; max 4 weeks if custom-configured. FedEx/UPS/DHL handled—all tracked.

Installation & Maintenance Reality Check

Skip the fancy climate-controlled room—it fits standard 19″ cabinets (IEC 60297-3 compliant) but needs 50mm clearance above for airflow. One caveat: don’t cram it next to VFDs; keep 200mm separation to avoid noise. For maintenance? Wipe vents quarterly (dust buildup kills electronics), and update firmware during planned outages—I’d schedule that yearly. Calibration checks every 18 months typically suffice unless you’re in a high-vibration zone. Safety-wise: always disconnect 24V power before swapping. Seems obvious, but I’ve seen shortcuts cause headaches.

Certifications That Actually Matter

CE, UL 61010-1, ATEX Zone 2 (for model 200-560-101-015), and ISO 9001-certified manufacturing. RoHS 3 compliant—no sneaky cadmium in these. The warranty covers defects in materials/workmanship, but excludes “oops-I-dropped-it-in-coffee” scenarios. From my experience, Vibro-meter’s support team responds to tech queries in under 4 business hours, which isn’t promised anywhere but consistently happens.

Reviews

There are no reviews yet.