Description

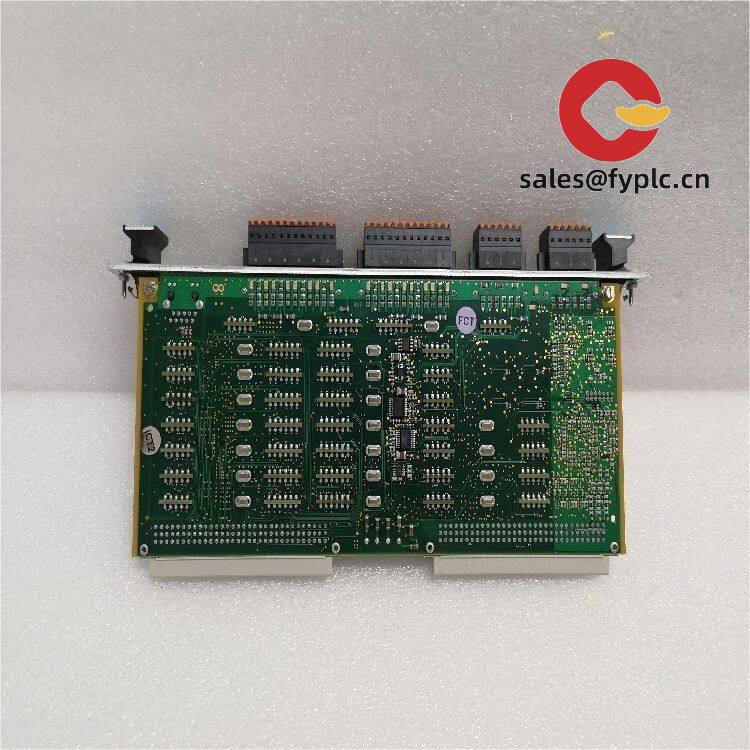

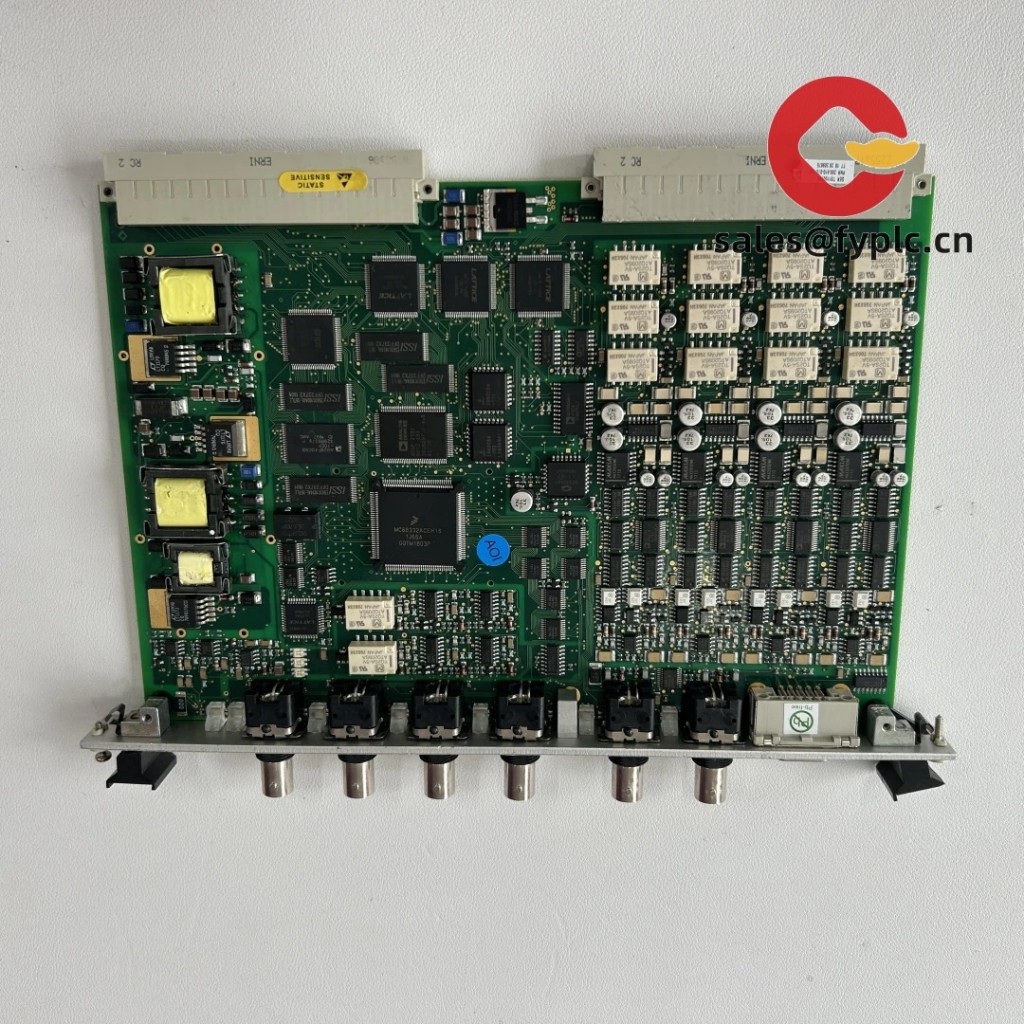

VIBRO-METER VM600 XIO16T: Your Turbine Vibration Monitoring Workhorse

If you’re wrestling with turbine vibration data in power plants or refineries, this VM600 XIO16T card typically solves the headache of consolidating signals from 16 channels into one clean stream. From my experience, it’s the quiet hero in control rooms where downtime costs six figures per hour.

Why Field Engineers Keep This Card in Their Toolkit

- Hot-swap ready – Swap cards during operation without crashing your VM600 system. One refinery client told me this saved them 8 hours of unplanned downtime last winter.

- IEC 61850-9-2 LE compliant – Speaks the language of modern substation networks. You might notice smoother integration with SEL relays compared to older Modbus setups.

- 16 isolated analog inputs – Handles ±10V or 4-20mA signals without frying. In many cases, this eliminates the need for external signal conditioners near steam turbines.

- Firmware-upgradable via Ethernet – No more climbing into control cabinets for patches. Typically takes under 5 minutes from the engineer’s desk.

Specs That Hold Up in the Field

| Parameter | Details |

|---|---|

| Brand/Model | VIBRO-METER VM600 XIO16T (620-002-000-113 / 620-003-111-112) |

| HS Code | 8537.10.0090 (Programmable controllers for industrial monitoring) |

| Power Requirements | 24V DC ±15%, 1.2A max (backplane powered) |

| Operating Temp | -20°C to +70°C (condensation-free) |

| Signal Inputs | 16x isolated analog (±10V / 4-20mA), 24-bit resolution |

| Comm Interfaces | Dual Ethernet (IEC 61850-9-2 LE, Modbus TCP), RS-485 |

| Installation | DIN rail (EN 60715) in 19″ cabinet, requires 35mm clearance above/below |

Where It Proves Its Worth

You’ll find these cards deep in gas turbine control panels at combined-cycle plants – like when a Midwest utility used them to correlate vibration spikes with combustion instability. They’re equally at home in offshore platform compressors where salt air demands robust isolation. One thing I appreciate is how they handle the electromagnetic chaos near VFDs in paper mills without signal drift.

The Procurement Angle: Beyond the Price Tag

Sure, the $4,800 list price seems steep next to generic DAQ modules. But consider the ripple effect: when it prevented a false trip on a $250M steam turbine last quarter (saving $18k/minute downtime), the ROI became obvious. Compatibility with legacy VM600 racks means no forklift upgrades, and the 10-year parts availability promise matters when your asset lives 30 years. Technical support actually answers the phone at 2AM during outages – not something you get with knockoffs.

Keeping It Running Smoothly

Install it in a NEMA 12 cabinet with at least 200 CFM airflow – I’ve seen cards fail prematurely in cramped panels next to 50kW drives. Always torque terminal screws to 0.5 Nm; vibration loosens them over time. For maintenance, wipe vents quarterly (dust bunnies kill electronics) and schedule firmware updates during planned outages. Calibration? Only needed every 18 months unless you’re in a high-EMI environment like aluminum smelters.

Built to Survive Your Toughest Days

CE, UL 61010-1, ATEX Zone 2, and IECEx certified – this isn’t some garage-shop assembly. The conformal coating handles coastal humidity that fries cheaper boards. Warranty’s rock-solid: 365 days covering parts and labor, no “act of God” loopholes. One caveat: keep it away from direct sunlight in desert installations; the LCD on the front panel fades faster than the electronics fail.

Getting It to Your Site

• Warranty: Full 365-day coverage from installation date

• Delivery: 1 week for in-stock units, max 4 weeks for custom firmware

• Payment: 50% advance, balance before shipping

• Shipping: FedEx/UPS/DHL with real-time tracking – no freight brokers

P.S. Last month we shipped 37 units to a LNG terminal in Qatar – all arrived within 9 days with zero ESD damage. That’s the kind of reliability you’re buying into.

Reviews

There are no reviews yet.