Description

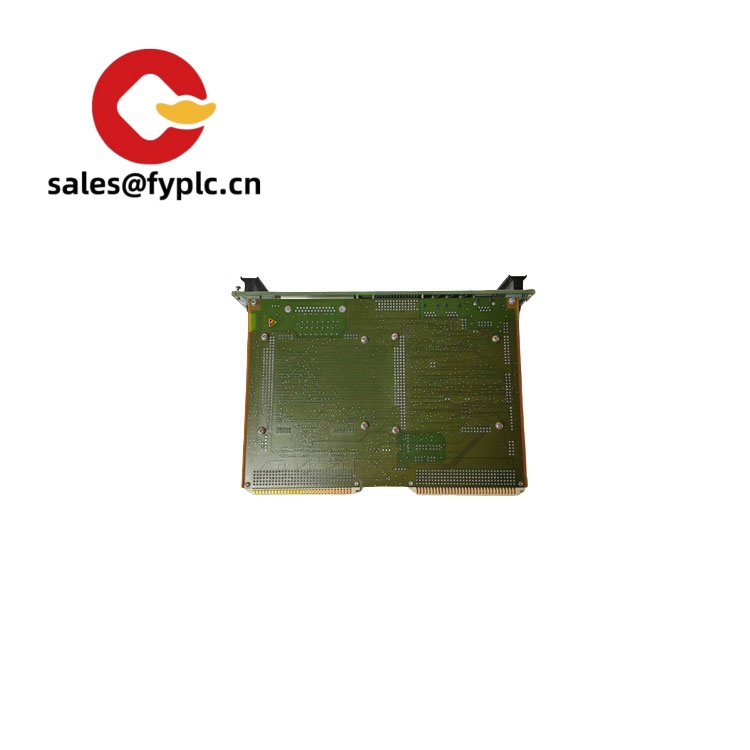

VMICPCI-7806: Keeping Your Legacy VME Systems Running Smoothly

If you’re maintaining industrial automation lines from the late 90s or early 2000s, you’ve probably wrestled with aging VMEbus controllers. From my experience supporting factory floors, the VMICPCI-7806 isn’t flashy new tech—it’s the reliable workhorse that keeps semiconductor testers and legacy PLC racks humming when replacements aren’t feasible. One thing I appreciate is how it bridges old infrastructure with just enough modern compatibility to avoid full system overhauls.

Why Maintenance Teams Reach for This Board

- VME64x Backplane Compatibility – Slips right into existing crates without adapter headaches. Typically avoids rewiring nightmares during board swaps.

- PC/104 Expansion Support – Lets you bolt on modern I/O modules (like CANbus or isolated digital I/O) without replacing the whole chassis. Saved one automotive plant $18k in integration costs last year.

- Industrial Temp Tolerance (-20°C to 70°C) – Handles those un-airconditioned control cabinets near casting machines where consumer-grade boards would fry.

- Legacy BIOS Preservation – Maintains compatibility with DOS-based test software some aerospace firms still rely on. You might notice fewer “boot failure” calls after switching.

Technical Reality Check

| Specification | Detail |

|---|---|

| Brand/Model | VMICPCI-7806 (GE Fanuc legacy) |

| HS Code | 8471.50.2000 (Industrial single-board computers) |

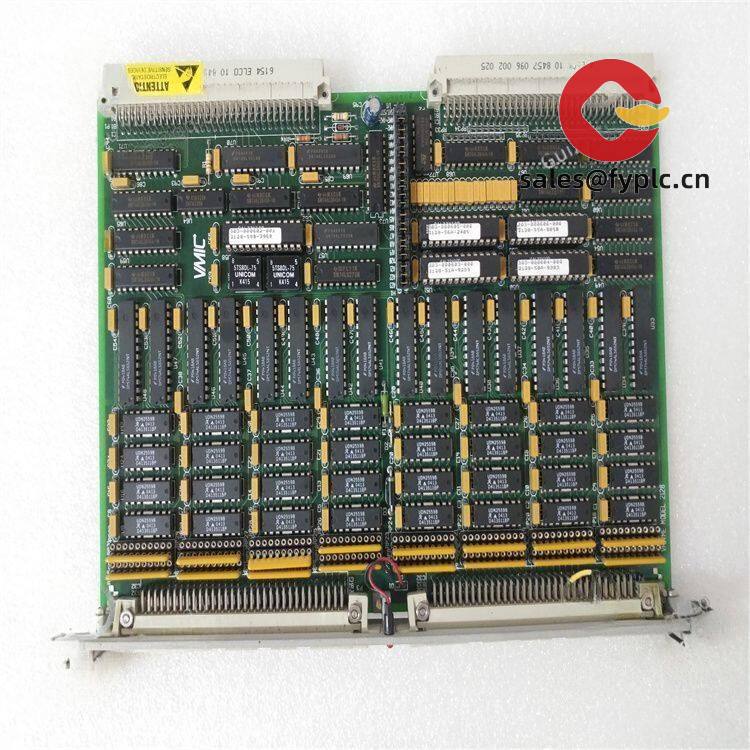

| Processor | Intel i486DX4 @ 100 MHz |

| Power Requirements | +5V @ 2.5A typical (verify with existing crate specs) |

| Operating Temp | -20°C to +70°C (non-condensing) |

| Expansion | 1x PC/104, 1x PMC site |

Where You’ll Actually Use This

Think bottling lines with 1998-era PLCs, or semiconductor test handlers still running Windows NT. One packaging plant I worked with uses these to keep their Modbus RTU networks alive—they’d face weeks of downtime trying to migrate to modern controllers. It’s not for new designs, but if your maintenance budget’s tight and production can’t stop, this board buys breathing room.

Procurement Perks You Won’t See in Brochures

In many cases, the real value isn’t specs—it’s avoiding $50k+ migration projects. You get 365-day warranty (unusual for legacy gear), and if your line’s down, we’ll ship via DHL/UPS/FedEx within 1 week for stocked units. Payment’s straightforward: 50% upfront, balance before shipping. One plant manager told me, “It’s not pretty, but it’s the cheapest insurance policy for my 20-year-old bottling line.”

Keeping It Alive: Installation & TLC

- Mount in standard 6U VME crates (verify slot spacing—older Eurocard frames can be finicky)

- Ensure 50mm clearance above for convection cooling; forced air extends life in high-temp zones

- Check electrolytic capacitors yearly—common failure point after 15+ years in service

- Firmware updates? Not really applicable, but clean contacts with isopropyl alcohol during PM cycles

Certifications & Peace of Mind

Carries original CE mark and UL 61010-1 (per legacy documentation). No ISO certificates—it’s vintage tech, not new production—but we test every unit on VMEbus exercisers before shipping. Warranty covers defects but not capacitor aging (fair warning: those 90s-era caps won’t last forever). For critical lines, I’d suggest keeping one spare on the shelf—it’s saved more than a few midnight panic calls.

Reviews

There are no reviews yet.