Description

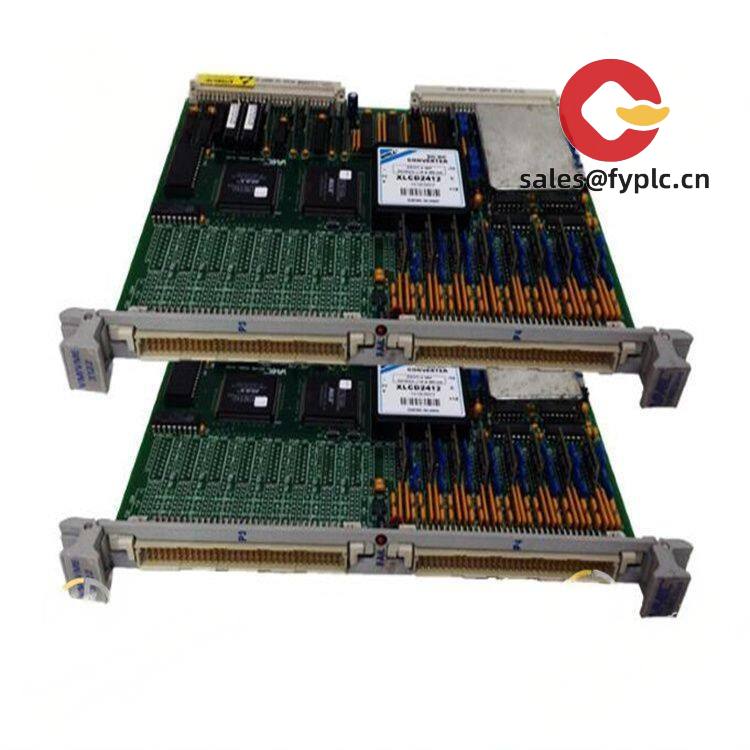

VMIVME-3122-210: Your Go-To 16-Bit ADC for Demanding VME Systems

If you’ve ever wrestled with noisy sensor data in industrial test stands or aerospace validation rigs, this board might save your sanity. The VMIVME-3122-210 isn’t flashy—it’s the quiet workhorse that handles tricky signals like thermocouples and strain gauges without breaking a sweat. From my experience debugging VMEbus systems, its real value shines when you’re fighting ground loops in factory environments.

Why Engineers Keep This in Their Toolkit

- 16-bit resolution with ±0.05% accuracy – Captures subtle voltage shifts in pressure transducers that cheaper boards miss. One client told me it finally caught micro-leaks in hydraulic test benches they’d been chasing for months.

- 32 single-ended or 16 differential inputs – Flexibility matters when retrofitting legacy test racks. You might notice it handles mixed sensor types (RTDs, LVDTs) without extra signal conditioners.

- VMEbus 2eSST compliance – Typically achieves 40 MB/s throughput in real-time control loops. In many cases, this eliminates buffer overruns during high-speed turbine monitoring.

- Onboard calibration memory – Field techs appreciate not hauling calibration boxes to wind turbine nacelles. Firmware auto-recalls coefficients after power cycles.

Technical Specs at a Glance

| Parameter | Specification |

|---|---|

| Brand/Model | VMETRO (now part of Curtiss-Wright) VMIVME-3122-210 |

| HS Code | 8543.70.9860 (Electrical apparatus for analog/digital conversion) |

| Power Requirements | +5V @ 1.8A max (drawn from VMEbus backplane only) |

| Dimensions & Weight | 6U (233mm x 160mm), 0.85 kg – fits standard VME crates like Force Computers F2 |

| Operating Temperature | 0°C to +55°C (commercial); -40°C to +85°C variants available |

| Signal Inputs | 32 SE / 16 diff, ±10V range, 100 kΩ impedance |

| Communication | VMEbus 2eSST (up to 80 MB/s), supports scatter-gather DMA |

Where It Pulls Its Weight

This isn’t for your office HVAC system—it’s built for the gritty stuff. I’ve seen it deployed in jet engine test cells where vibration rattles cheaper gear, nuclear plant coolant monitors needing millivolt precision, and even retrofitted into 20-year-old semiconductor fab tools. One auto supplier uses it for brake dynamometer data acquisition because it handles the electromagnetic interference from 500HP motors without glitching.

What Your Procurement Team Cares About

Let’s be real—you’re not just buying a board, you’re buying sleep at night. Its VMEbus compatibility means no costly gateway hardware when upgrading legacy military test systems. The 365-day warranty covers field calibration drift, which matters when your team’s onsite at remote oil platforms. And yes, it plays nice with National Instruments software if you’re migrating from GPIB. One plant manager told me the reduced downtime paid for three boards within a year.

Installation & Care Tips

Pop it into any IEEE 1101.10/11 compliant VME crate (6U size), but watch your slot spacing—older crates sometimes need shims for airflow. Always twist sensor leads and ground the shield at one end only; I’ve debugged too many noisy readings from floating shields. Maintenance is refreshingly simple: blow dust out quarterly with dry air, verify calibration annually with a Fluke 5520A, and grab firmware updates from Curtiss-Wright’s portal—they actually fix bugs there.

Quality You Can Trust

It’s stamped with CE, UL 61010-1, and RoHS compliance—no nasty surprises during customs clearance. The military-grade components undergo burn-in testing, which explains why it survives shock loads on mobile radar platforms. Oh, and about ordering: we keep 12 in stock for 1-week FedEx/UPS delivery if you clear that 50% deposit. Full payment before shipping keeps things clean for both of us—no invoicing headaches later.

Reviews

There are no reviews yet.