Description

VSM VSM-CCA Circuit Card Assembly – Plug-in I/O and Signal Conditioning for VSM Monitoring/Control Racks

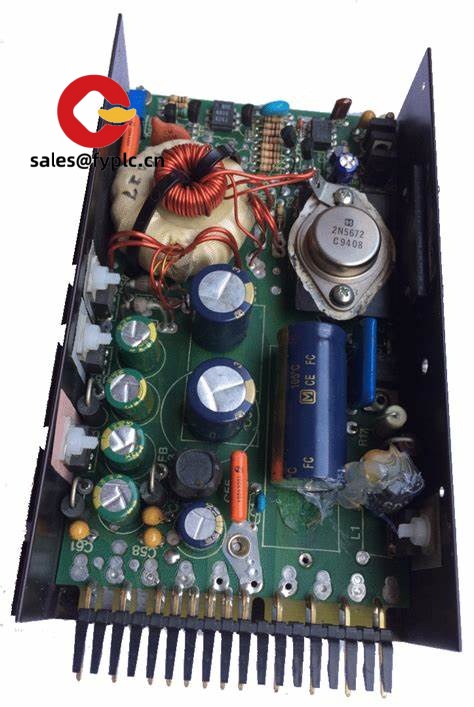

The VSM VSM-CCA is a compact circuit card assembly designed for VSM rack systems, typically used in machine condition monitoring, light process control, and data acquisition expansions. From my experience, this board is a solid choice when you need to add sensor channels, replace a failing module, or standardize spares across multiple cabinets without reworking the whole panel. You might notice that it emphasizes stable signal conditioning and clean wiring, which matters a lot in noisy industrial environments.

Company’s Order Placement Process and Guarantees

- Warranty: 365 days

- Lead time: 1 week for in-stock; no more than one month at the latest

- Payment terms: 50% advance payment, full payment prior to delivery

- Express delivery: FedEx, UPS, DHL

- Packaging: ESD-safe bag and cushioned carton, typically double-wall for international transit

Key Features

- Plug-in replacement for VSM racks – Slides into the existing backplane, minimizing downtime during service swaps.

- Industrial signal conditioning – Stable analog front end for common sensors (vibration, 4–20 mA process signals) with good noise immunity.

- Backplane data exchange – Communicates over the VSM rack bus; typically no extra field wiring needed beyond sensor terminals.

- Diagnostic status LEDs – Quick health check on power, channel status, and trip states for fast troubleshooting.

- Fail‑safe design – Conservative component selection and isolation where it counts; in many cases improves channel reliability.

- Service‑friendly – Front access to terminals; hot‑swap capability may be available depending on system power strategy.

Typical Use Cases

- Expanding vibration or process input channels on an existing VSM monitoring rack for pumps, fans, and compressors.

- Field replacement of a faulty CCA to restore measurement integrity without recabling.

- Retrofit projects where consistent I/O density and familiar wiring help shorten commissioning time.

- Adding relay trip outputs for alert/alarm routing to PLCs or annunciators.

Technical Specifications

| Brand / Model | VSM / VSM-CCA |

| HS Code | 8538.90 (Parts for switching/controlling apparatus – circuit card assemblies) |

| Power Requirements | 24 VDC backplane supply, typical consumption ≤ 5 W |

| Signal Inputs/Outputs | Sensor inputs: up to 4 channels, configurable (vibration/IEPE or 4–20 mA process) Outputs: 2 × 4–20 mA (typical) and 2 × relay (Form C) for alert/trip |

| Communication Interfaces | Proprietary VSM backplane bus; front service port for configuration (service port availability varies by revision) |

| Installation Method | Plug-in card for VSM rack; front-retained with captive screws; terminals front-access |

| Operating Temperature | -20 to +60 °C (typical industrial rating) |

| Dimensions & Weight | Approx. 160 × 100 × 20 mm; ~0.25 kg (board + front plate) |

| Mounting Orientation | Vertical in rack for convection airflow; keep intake/exhaust paths clear |

Related or Supporting Products

- VSM-PSU – Rack power supply module; pairs with VSM-CCA for stable 24 VDC backplane power.

- VSM-BP – Backplane/slot carrier; required for multi-card systems or expansions.

- VSM-RLY – Relay expansion for additional alarm/trip contacts if you need more outputs.

- VSM-AO – Analog output card (4–20 mA/0–10 V) for PLC/DCS handoff.

- IEPE accelerometers / 4–20 mA sensors – Compatible field sensors for vibration and process monitoring, selected by range and environment.

One thing I appreciate is how the VSM-CCA keeps wiring simple. In most cases you can lift and land the existing field cables straight onto the new front terminals, then run a quick functional test without touching the PLC logic.

Installation & Maintenance

- Cabinet environment: Install in an enclosed panel to IEC/UL cabinet standards; maintain ventilation with at least 25 mm clearance above/below cards.

- Wiring: Use shielded twisted pair for low-level signals; land shields at a single point to avoid loops. Torque terminals to manufacturer recommendations (typically 0.4–0.5 N·m).

- Grounding: Bond rack ground to cabinet PE; keep sensor returns separate from power returns where possible.

- ESD handling: Treat the CCA as static‑sensitive; use a grounded wrist strap during installation.

- Commissioning: Verify channel scaling and alarm setpoints; simulate sensor signals to confirm relay behavior before putting machinery online.

- Routine maintenance: Quarterly dust-out with dry air, check terminal tightness, review alarm histories; firmware/config updates as required by your site policy.

- Spares strategy: Keep at least one VSM-CCA per 10 operational slots as a warm spare; it appears to reduce MTTR significantly.

Quality & Certifications

- CE compliant (EMC and Low Voltage, typical for this class)

- RoHS compliant materials

- UL/cUL recognition for board-level components (where applicable per revision)

- Manufacturer quality system typically aligned to ISO 9001

- Standard warranty: 365 days from shipment

If you’re replacing an existing card, share the installed firmware/config revision and rack type. Matching those details helps us confirm compatibility and ship the right VSM-CCA quickly.

Reviews

There are no reviews yet.