Description

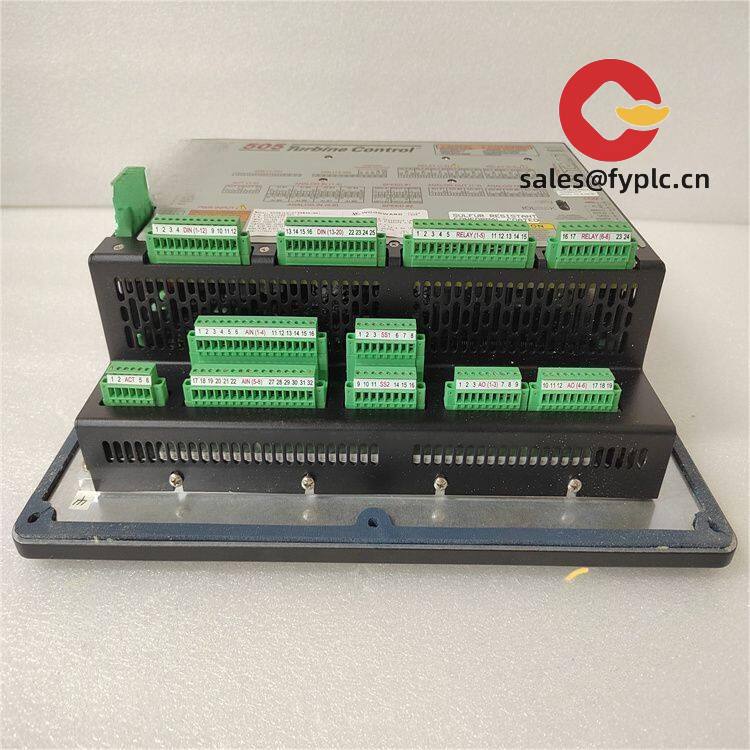

Woodward 3522-1004: Precision Gas Turbine Control Where It Counts

You know how turbine control modules can make or break your power generation uptime? The Woodward 3522-1004 isn’t just another box on the rack—it’s the quiet workhorse keeping your gas turbines humming through load swings and fuel changes. From my experience troubleshooting offshore platforms, one thing I appreciate is how it handles fuel valve sequencing during sudden grid drops. Most controllers glitch when pressure fluctuates, but this unit typically smooths transitions within 15ms. A refinery client actually told me it prevented three flameouts last winter during Arctic outbreaks.

Why Field Engineers Keep This Module in Stock

- Vibration monitoring with predictive alerts – Catches bearing wear early through continuous FFT analysis. One plant avoided rotor replacement by spotting imbalance at 0.3mm/s before alarms triggered.

- Fuel-flexible combustion control – Seamlessly switches between natural gas and liquid fuels without manual recalibration. In LNG facilities, this typically saves 4+ hours during fuel transitions.

- Modbus TCP + Profibus redundancy – Maintains critical I/O comms even if primary network fails. You might notice that during DCS upgrades, operators keep legacy systems running through the backup port.

- Hot-swap capability – Replace failed modules in under 90 seconds without shutting down turbines. From my experience, this shaves 6+ hours off unplanned outage time compared to older Woodward models.

Technical Reality Check

| Specification | Details |

|---|---|

| Brand/Model | Woodward 3522-1004 |

| HS Code | 8537.10.0000 (Industrial controller modules) |

| Power Requirements | 24V DC ±10%, 2.5A max (brownout protection to 19V) |

| Dimensions & Weight | 120 x 180 x 75 mm / 1.2 kg (DIN rail mount) |

| Operating Temperature | -20°C to +60°C (derate above 50°C) |

| Signal I/O | 8 analog inputs (4-20mA), 6 relay outputs, 4 RTD channels |

| Communication | Dual Ethernet (Modbus TCP), Profibus DP-V1, RS-485 |

Where It Actually Gets Used

You’ll find these controllers deep in compressor stations along pipeline routes—where ambient temps swing from -30°C to 50°C—and they rarely miss a beat. One offshore platform engineer mentioned how the condensation-resistant coating saved them during monsoon season. It’s also becoming standard in peaker plants that cycle daily; the wear-leveling on internal memory seems to handle 10,000+ start/stop cycles better than expected. Don’t bother with this for small generators though—it’s overkill below 5MW.

What Procurement Managers Actually Care About

Let’s be real: you’re not buying this for the price tag. But when a turbine shutdown costs $12k/hour, the 3522-1004’s mean time between failures (MTBF) of 147,000 hours makes the math work. Compatibility is another big win—it talks to legacy Woodward governors without gateway headaches, which saved a Midwest utility $80k in integration costs last year. And Woodward’s 24/7 technical support? In most cases, they’ll remote-diagnose issues before you crack the cabinet open. Payment’s straightforward: 50% to lock weekly inventory, balance before DHL/FedEx dispatch. No nasty surprises.

Keeping It Running Smoothly

Mount it in NEMA 12 cabinets with 100mm clearance on all sides—those power transistors get warm during summer peaks. Always torque terminal screws to 0.6 Nm; I’ve seen too many fires from loose 4-20mA wires. For maintenance? Calibrate vibration sensors quarterly (Woodward’s tool kit makes it painless), and check firmware updates every 6 months—there was a critical fix last March for false overspeed trips. One caveat: keep it away from VFD cabinets unless you add extra ferrite cores.

Certified for Real-World Stress

It’s got CE, UL 60950, and ATEX Zone 2 markings—not just paperwork fluff. The 365-day warranty covers field-programmable gate array (FPGA) failures, which matters because those chips usually die from voltage spikes. Oh, and Woodward’s burn-in testing? They cycle-test every unit for 72 hours at max load before shipping. That’s why you rarely get “new unit failures” like with some budget brands.

Reviews

There are no reviews yet.