Description

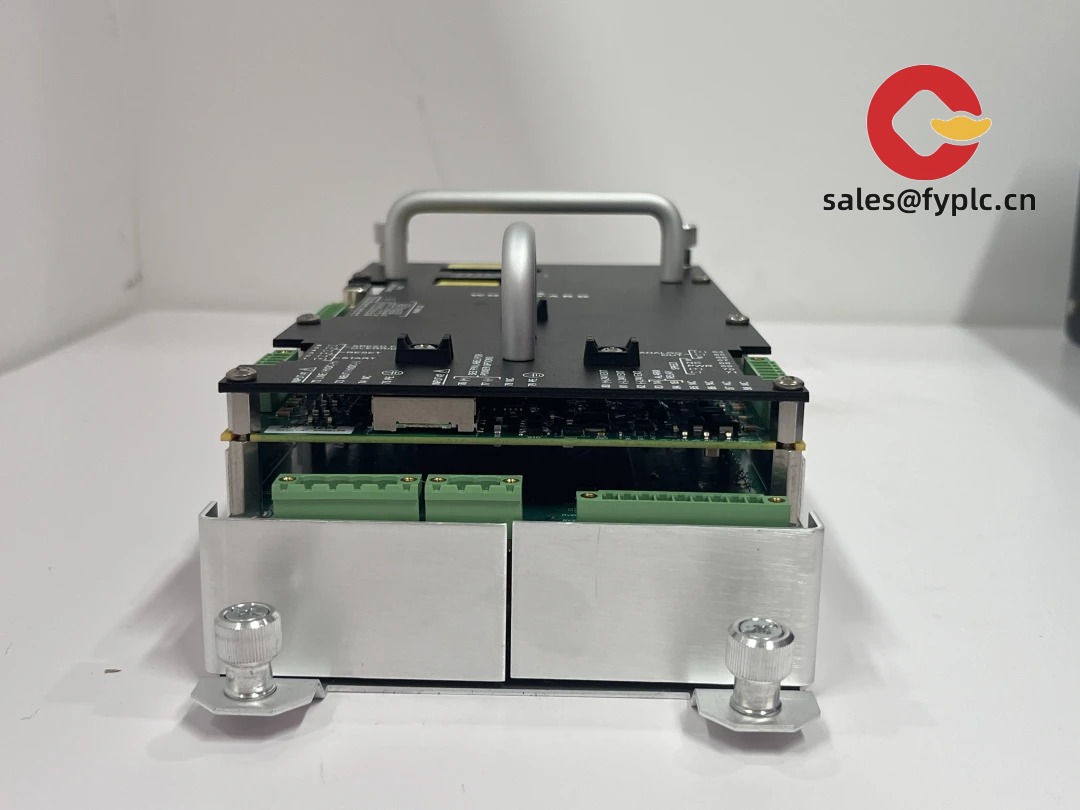

WOODWARD 5437-1119 – High‑reliability control module for MicroNet/MicroNet TMR systems

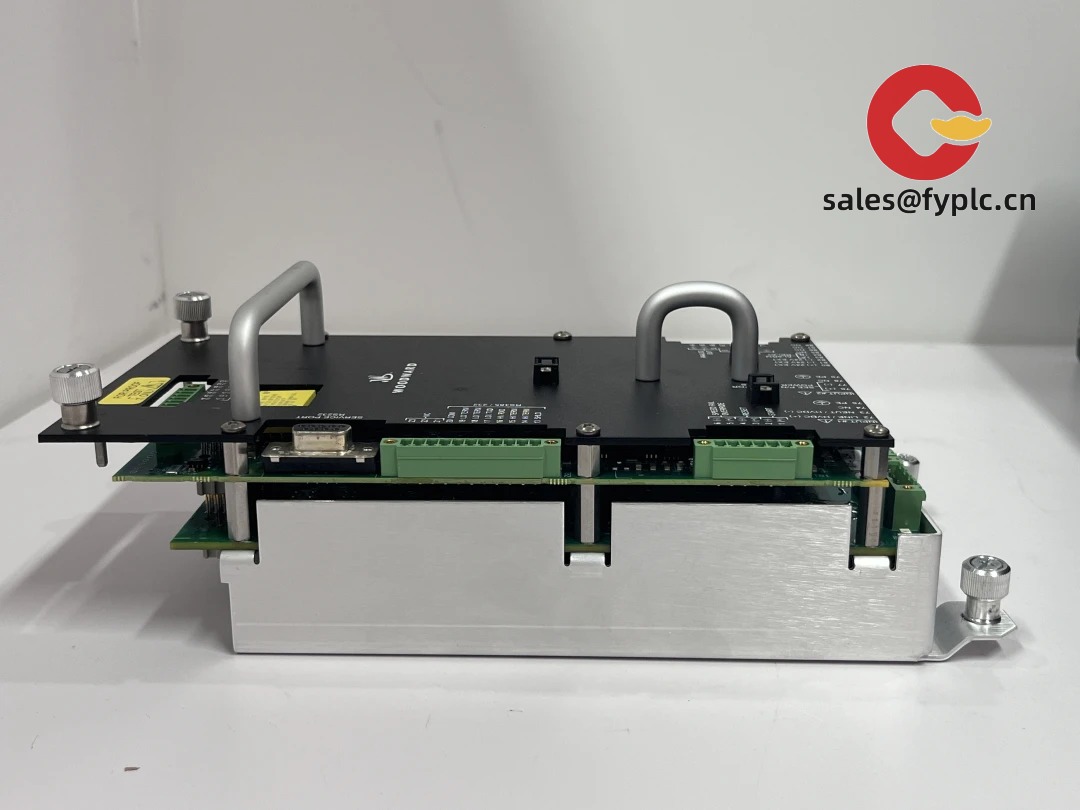

The WOODWARD 5437-1119 is a plug‑in module designed for Woodward MicroNet platforms, including TMR configurations used on critical rotating equipment. From my experience, this series is typically chosen by plants running gas or steam turbines, compressors, and large generator sets where high availability, deterministic control, and straightforward serviceability matter more than anything else. You might notice that the card follows Woodward’s familiar rack form factor, so swaps and upgrades are usually quick—minimizing outage time in most cases.

Company’s Order Placement Process and Guarantees

- Warranty: 365 days

- Delivery: 1 week if in stock; no more than one month at the latest

- Payment: 50% advance payment; full payment before delivery

- Express options: FedEx, UPS, DHL

Key Features

- MicroNet / TMR compatibility: Built for Woodward rack-based control systems used in high-availability environments.

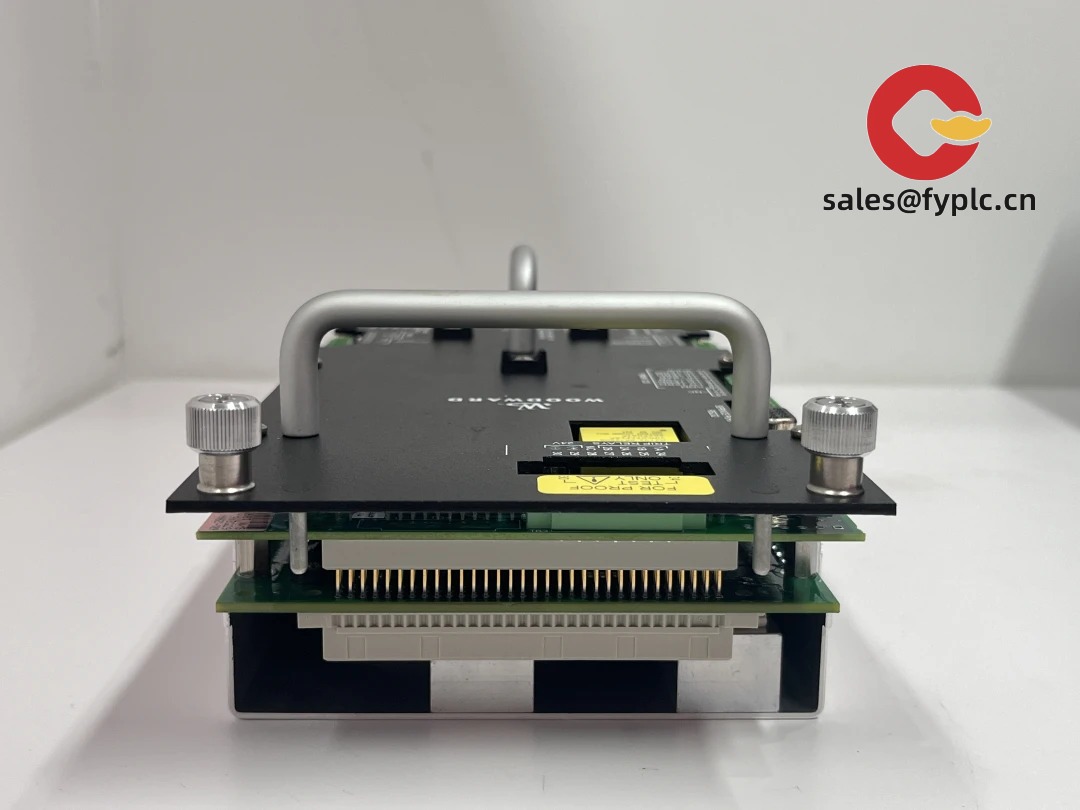

- Backplane architecture: High-speed communication over the chassis backplane; field I/O is handled via terminal boards for clean wiring.

- Service diagnostics: Front-panel status LEDs and, in many cases, a service/diagnostic access point for quick checks.

- Industrial temperature design: Suitable for typical control cabinet conditions encountered in power and process plants.

- Revision-managed firmware: Supports controlled firmware versions to match existing site standards and validation packs.

- Ease of replacement: Plug-in installation helps reduce MTTR; technicians usually restore the loop quickly after a health check.

- Robust build: Conformal coating and conservative component selection aimed at long service life.

Technical Specifications

| Brand / Model | WOODWARD 5437-1119 |

| HS Code (6‑digit) | 8538.90 (Parts suitable for use with industrial control apparatus) |

| Power Requirements | Supplied via chassis backplane from a 24 VDC (nominal) system PSU; module consumption typically <10 W |

| Dimensions & Weight | Rack plug‑in (approx. 6U card); typical depth ~280 mm; weight ~0.9–1.2 kg (approx.) |

| Operating Temperature | Typically 0 to +60 °C; storage −40 to +85 °C (refer to the module’s datasheet for exact limits) |

| Signal Input/Output Types | Module-dependent; integrates with MicroNet terminal boards for discrete and/or analog channels as configured |

| Communication Interfaces | High-speed system backplane; front maintenance/diagnostic access may be available depending on revision |

| Installation Method | Plug-in card for Woodward MicroNet/MicroNet TMR chassis; field wiring via matching terminal boards |

Application Fields

This model is typically applied in turbine and engine control environments where deterministic logic and redundancy are needed. Common scenarios include:

- Gas and steam turbine governing and protection

- Large compressor trains and pipeline stations

- Generator set control and synchronization packages

- Industrial boilers and process plant balance-of-plant controls

- Marine propulsion and auxiliary power systems

A quick example from the field: a power customer replaced a 5437-xxxx series card during a scheduled stop; with a firmware match and a configuration restore, the unit was back in service in under an hour—no wiring changes, just a clean reseat and verification. That seems to be the norm when the rack and terminal boards are healthy.

Advantages & Value

- Reliability: Mature platform favored in critical-duty applications; supports redundant architectures.

- Compatibility: Matches existing Woodward racks and backplanes, reducing retrofit scope.

- Downtime savings: Plug-in replacement typically shortens maintenance windows and recovery time.

- Lifecycle support: Documented firmware revisions and configuration control help standardize fleets.

- Procurement clarity: Known form factor, predictable lead times, and stable inventory planning.

Installation & Maintenance

- Cabinet environment: Install in a clean, ventilated control cabinet; maintain ambient within the specified range.

- Power quality: Ensure stable 24 VDC supply to the chassis PSU; follow site EMC and grounding practices.

- ESD handling: Use wrist straps and ESD-safe procedures; avoid touching connector pins.

- Card seating: Align guides, insert evenly, and secure captive screws to the recommended torque.

- Configuration & firmware: Match firmware revisions; back up and restore configurations before/after replacement.

- Routine care: Periodic dust removal with dry air, connector inspection, and verification of LED/status logs.

- Calibration: If the module involves analog I/O, verify scaling/calibration after installation.

Quality & Certifications

- Manufactured under ISO 9001 quality systems (typical for Woodward production)

- CE and UL/cUL compliance for industrial control equipment (model/revision dependent)

- RoHS applicability varies by revision; confirm for your exact 5437-1119 release

- 365-day warranty coverage as stated above

Recommended Accessories & Compatibility

- Woodward MicroNet or MicroNet TMR chassis (matching slot count and backplane)

- 24 VDC chassis power supply modules and recommended surge protection

- Compatible terminal boards for field I/O, with shielded cabling as per site EMC practices

- Maintenance items: front-panel retention hardware, labeling kits, and spare fuses (if used in the rack PSU)

Reviews

There are no reviews yet.