Description

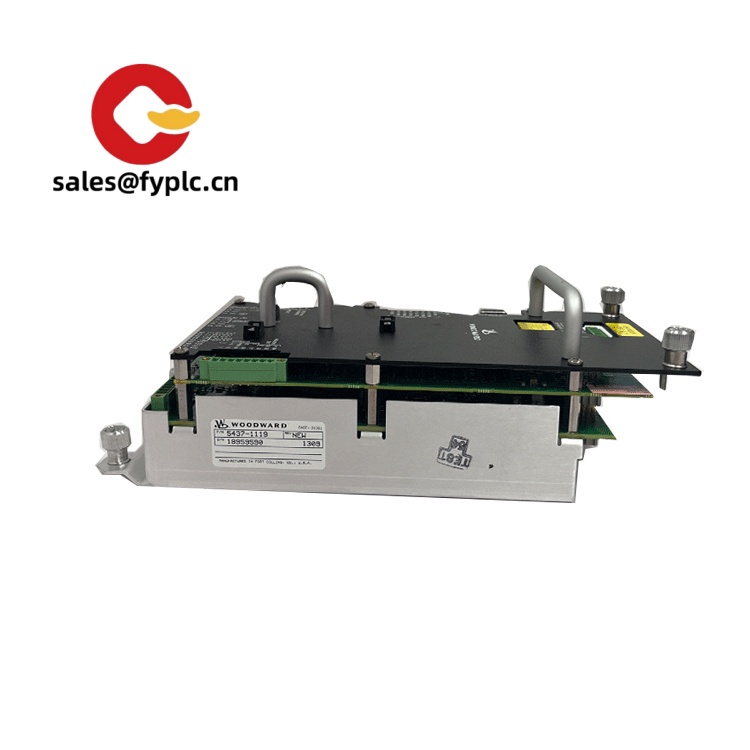

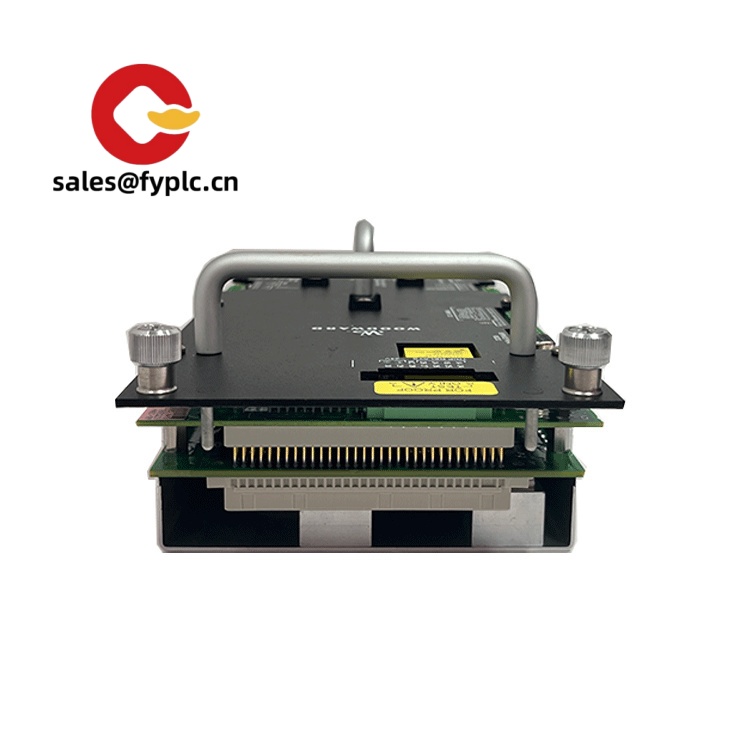

Woodward 5437-1119: Your Turbine’s Last Line of Defense

You know how turbine overspeed events can escalate from “huh” to “oh crap” in milliseconds? That’s where this ProTech GII module earns its keep. I’ve seen it shut down 50MW steam turbines cleanly during emergency trips – not the flashy part of the control system, but absolutely the one you pray works when alarms start screaming.

Why Plant Engineers Keep This in Their Spares Cabinet

- Triple Modular Redundancy (TMR) – Runs three independent processors voting on every action. One fails? The other two keep guarding your turbine. Not something you want failing during a black start.

- SIL 3 Certified – Meets IEC 61508 standards out of the box. One refinery client told me this shaved six weeks off their safety system certification process.

- Hot-Swappable – Replace modules without shutting down the turbine. Had a paper mill guy text me at 2AM saying he swapped one during a fiber buildup incident – saved them 12 hours of downtime.

- Legacy Signal Support – Handles 4-20mA, 0-10V, and TTL inputs alongside modern Modbus. Keeps older plants from rewiring entire control rooms.

Technical Reality Check

| Specification | Detail |

|---|---|

| Brand/Model | Woodward ProTech GII 5437-1119 |

| HS Code | 8537.10.0090 (Digital controllers) |

| Power Requirements | Nominal 24V DC (18-32V range) |

| Dimensions & Weight | 120 x 180 x 100mm / 1.8kg |

| Operating Temp | -20°C to +70°C (derate above 55°C) |

| Signal I/O | 8 configurable inputs (prox, LVDT, RTD), 4 relay outputs |

| Comms | Modbus RTU over RS-485, optional Ethernet |

Where It Actually Gets Used

You’ll find these guarding critical rotating equipment where failure means catastrophic damage. Like in offshore gas compression trains – one North Sea platform engineer mentioned how it caught a governor valve sticking during a storm. Or chemical plants during catalyst regeneration when turbine loads swing wildly. Not for your garden-variety pumps, but where a $2M turbine could become shrapnel in 8 seconds.

Why Procurement Teams Actually Approve This Budget

Let’s be real – it’s not the cheapest option. But from my experience, the TMR architecture means fewer false trips than dual-redundant systems. One client calculated $187k in avoided downtime per year after switching from their old system. And Woodward’s global service network? Had a tech onsite in Monterrey within 18 hours when a module failed – not something you get with boutique suppliers. Typically pays for itself in one avoided emergency shutdown.

Installation Reality Check

Mount it in a NEMA 1 cabinet with at least 100mm clearance top/bottom – those power supplies get toasty. Keep it away from VFDs; I’ve seen EMI cause phantom trips when wiring wasn’t segregated. Calibration? Every 24 months unless you’re in a high-vibration environment (like that cement plant in Arizona that does it quarterly). And for heaven’s sake, update firmware during planned outages – not when the turbine’s screaming at 110% speed.

No-Spin Certifications & Guarantees

CE marked, UL 60730 certified, SIL 3 per IEC 61508. RoHS compliant because nobody needs lead in their control room. 365-day warranty – which feels short until you realize these modules typically run 15+ years. If we have it in stock (check our live inventory), we ship FedEx/UPS/DHL in 5 business days. Payment’s 50% upfront, balance before shipping. No credit card fees, no hidden charges – just the module and documentation you need to keep turbines spinning safely.

Reviews

There are no reviews yet.