Description

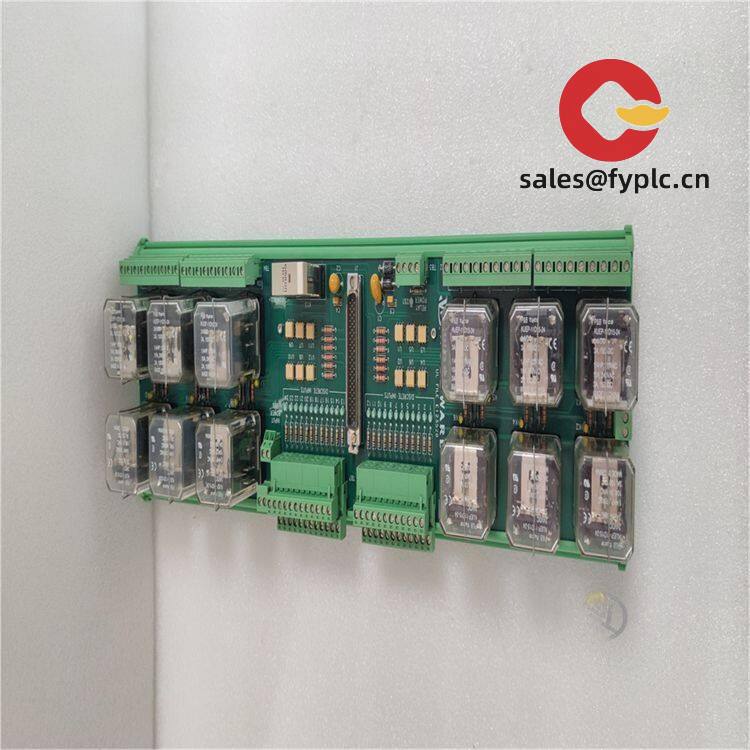

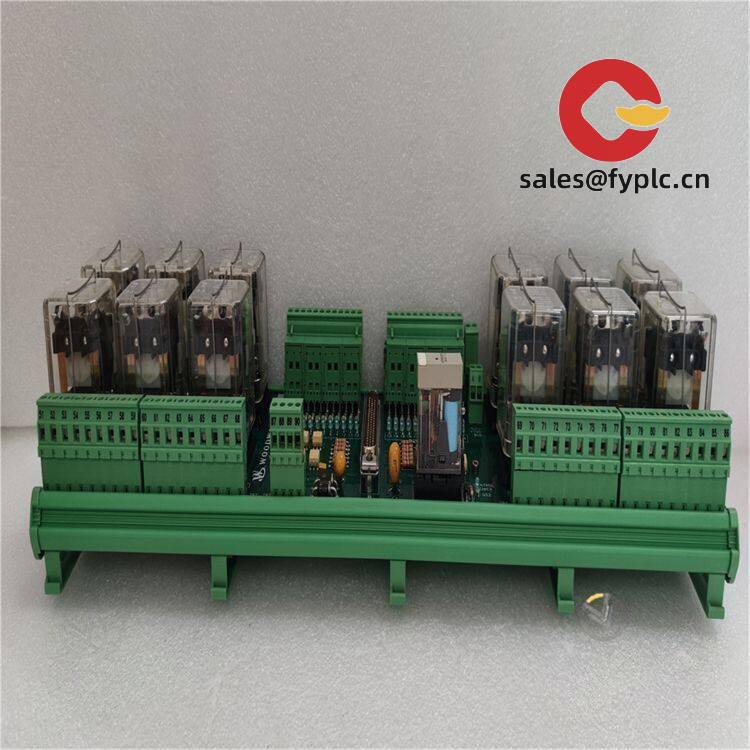

Woodward 5441-693 Control Module – Reliable Replacement for Turbine & Generator Control Racks

The Woodward 5441-693 is a rack-mounted control module used in Woodward industrial control systems, typically within turbine or generator control architectures. From my experience, it’s favored as a direct replacement part when plants want to restore system stability quickly without re-engineering the entire rack. You might notice that it’s designed to run off the backplane, which keeps wiring tidy and helps maintenance teams swap it with minimal downtime.

Order Placement Process and Guarantees

- Warranty: 365 days

- Delivery: 1 week if in stock; no more than one month at the latest

- Payment: 50% advance payment; full payment prior to delivery

- Express options: FedEx, UPS, DHL

- Process: Confirm model and revision → Receive quotation → Issue PO and prepayment → Functional test & packing → Final payment → Express shipment with tracking

Key Features

- Backplane-powered design – Typically draws power from the control rack, avoiding external supplies and reducing wiring complexity.

- Industrial-grade build – Suited for continuous operation in turbine/generator environments where vibration and temperature fluctuate.

- Drop-in replacement – Intended as a like-for-like module swap to restore functionality fast, in many cases without logic or panel changes.

- Service-friendly front plate – Front access simplifies module insertion, securing, and field diagnostics.

- Rack-integrated I/O – Signals are handled through the system backplane, which keeps field cabling off the module face.

- Compatibility-focused – Works within Woodward system architectures; the exact role depends on rack configuration and firmware.

Technical Specifications

| Brand / Model | Woodward 5441-693 |

| HS Code | 9032.89 (Automatic regulating or controlling instruments; other) |

| Power Requirements | Supplied via system backplane; no external power input (typical for this series) |

| Operating Temperature | Typically 0 to +55 °C; verify against system build and site standards |

| Signal Input/Output Types | Handled through the rack backplane; function depends on configured role (digital/analog/logic as applicable) |

| Communication Interfaces | Proprietary backplane bus; no user Ethernet/serial on the front in most cases |

| Installation Method | Plug-in rack module; front-face locking screws for secure mounting |

| Dimensions & Weight | Rack plug-in format; contact us for the exact mechanical drawing for your revision |

Application Fields

Plants typically use the 5441-693 as part of a Woodward control rack in:

- Gas and steam turbine control systems (speed, load, protection integration)

- Generator control and synchronization panels

- Compressor / expander train controls in refining and petrochemical

- Industrial power islands and cogeneration skids

A maintenance lead from a combined-cycle plant told us they swapped this module during a planned outage and were back to full operation after a single restart—no logic edits required in their case. That seems to be the norm when the rack and firmware match.

Advantages & Value

- Reliability – Sourced and function-tested; we target low-risk commissioning with known-good modules.

- Compatibility – Selected to match your rack and revision level to avoid nuisance faults or firmware mismatches.

- Cost savings – A direct replacement usually costs less than redesigning the control or migrating platforms.

- Technical support – We help validate part numbers, backplane slot positions, and pre-shipment checks.

Installation & Maintenance

- Cabinet environment: Install in a clean, dry, ventilated control cabinet. Typically maintain ambient 0–55 °C and avoid corrosive atmospheres.

- ESD handling: Use wrist straps and ESD-safe packaging during unpacking and insertion.

- Power-down swap: In most systems, power down the rack and observe discharge wait times before removing the module.

- Seating & securing: Align with guides, press to fully seat the backplane connector, and tighten faceplate screws evenly.

- Wiring: Field wiring remains on terminal boards; confirm channel mapping and health in the HMI/engineering tool after restart.

- Routine care: Quarterly visual checks for dust, loose fasteners, and oxidation. Annual firmware/config verification if applicable to your system.

Quality & Certifications

- Typically supplied in compliance with CE requirements for industrial control equipment.

- UL/CSA conformity applies at the system level; this module is used within certified control assemblies.

- RoHS status depends on production date and revision; we can check by serial before shipment.

- 365-day warranty and full functional test report available upon request.

Related/Supporting Components

We can also support the surrounding hardware typically used with the 5441-693: system rack/chassis, power supply modules, controller/CPU cards, and terminal boards. If you provide your rack part numbers and firmware/logic snapshot, we’ll match compatible revisions to avoid mismatch alarms.

Reviews

There are no reviews yet.