Description

Woodward 5448-906 Control Module – Precision Speed/Load Control for Engine and Genset Governors

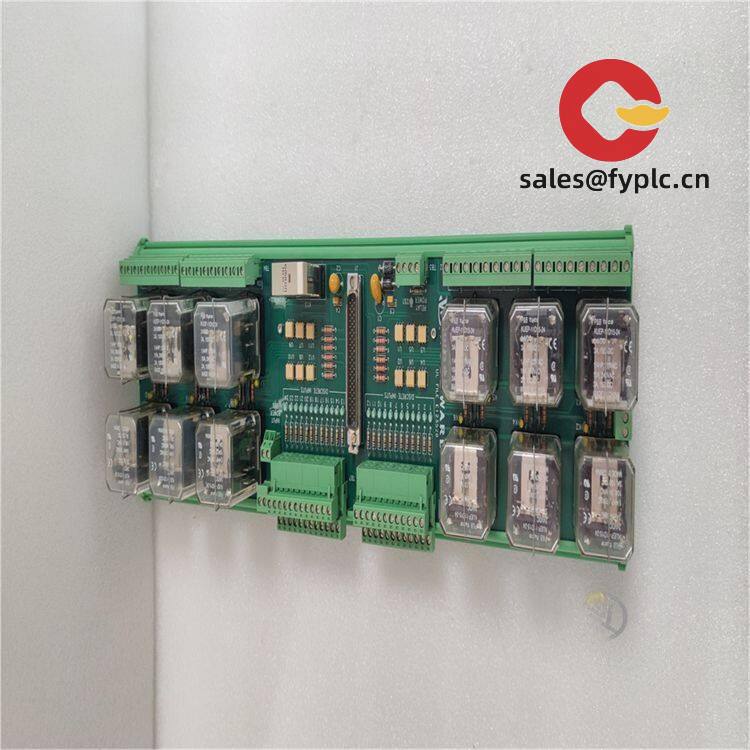

The Woodward 5448-906 is a factory control module used in engine and generator control systems where stable speed governing and dependable actuator drive are essential. From my experience, this board is typically found inside Woodward-based governor panels—supporting magnetic pickup speed sensing, analog speed reference, and proportional actuator output. It seems to be favored as a reliable replacement when older speed-control boards drift or when you need to restore tight governing on diesel or gas engines.

You might notice that the 5448-906 integrates smoothly with common Woodward ecosystems (e.g., EPG-style actuators and classic 2301/DSLC-based cabinets). That makes retrofit jobs a lot simpler and keeps downtime short, especially in plants where wiring and terminal designations are already standardized.

Company’s Order Placement Process and Guarantees

- Warranty: 365 days

- Lead time: 1 week if in stock; no more than one month at the latest

- Payment: 50% advance payment; full payment before delivery

- Express options: FedEx, UPS, DHL

Key Features

- Stable speed governing – Designed for tight isochronous or droop-style speed control in many engine applications.

- Magnetic pickup compatibility – Typically accepts MPU speed input for accurate, noise-resistant sensing.

- Proportional actuator drive – Drives Woodward proportional actuators commonly used in EPG/2301-type systems (current-output class).

- Analog setpoint integration – Works with external speed references or load-sharing signals found in legacy Woodward cabinets.

- Fast field replacement – Form-fit-function approach helps reduce panel rewiring and maintenance time.

- Industrial-grade design – Built for harsh plant environments with proper panel mounting and shielding practices.

Technical Specifications

| Brand / Model | Woodward 5448-906 |

| HS Code | 8537.10 (Boards, control panels for electric control/distribution, < 1000 V) |

| Power Requirements | 24 VDC nominal (typical for Woodward control modules; verify per cabinet BOM) |

| Signal Input / Output | MPU speed input (typical), analog speed reference; proportional actuator current output; discrete shutdown input (panel dependent) |

| Communication Interfaces | Not applicable for this analog control board; integrates via analog/discrete signals |

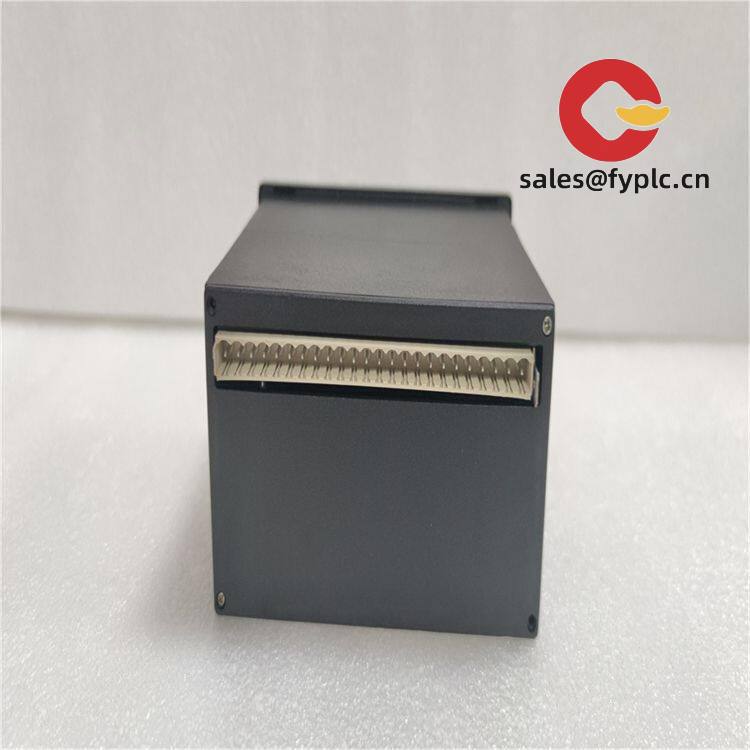

| Installation Method | Panel/cabinet integration; board-level module inside a protected control enclosure |

Note: Specific terminal numbering and calibration ranges vary by cabinet build. For safety, always match to your wiring diagram and the actuator model in service.

Application Fields

- Diesel and gas engine gensets requiring steady frequency control

- Oil & gas compressor and pump drives needing dependable governing

- Marine propulsion and auxiliary power units with analog governor panels

- Industrial CHP and standby power where legacy Woodward systems are installed

Advantages & Value for Procurement

- Reliability – Proven analog control approach, less sensitive to firmware issues and EMI when wired correctly.

- Compatibility – Plays well with Woodward actuators and common 2301/DSLC-style panels, reducing re-engineering.

- Cost control – Extends life of existing cabinets; avoids a full digital retrofit in many cases.

- Supportability – Clear test points and simple calibration steps make maintenance straightforward for plant technicians.

One thing I appreciate is how fast maintenance teams can swap this board during an outage window. Feedback we received from a refinery power group: “We dropped the 5448-906 into a 2301A panel, matched the pickup gap, and were back online within an hour—frequency drift disappeared.”

Installation & Maintenance

- Panel environment – Install in a clean, dry control cabinet (IP54 or better is typical). Provide ventilation to keep electronics within safe operating range.

- Wiring – Use shielded twisted pair for MPU leads; ground the shield at one end only to minimize noise. Keep high-current actuator wiring separate from low-level signals.

- Power – Stable 24 VDC supply with proper grounding and surge protection. Verify polarity prior to energizing.

- Calibration – Set speed reference and droop per site procedures. Confirm steady-state frequency and transient response under load steps.

- Routine checks – Inspect connectors for oxidation, tighten terminals, and clean dust with non-residue electronics spray. Check MPU air gap and actuator linkage.

- Documentation – Match to your cabinet drawings and actuator model; record setpoints for future reference.

Quality & Certifications

- Manufactured by Woodward, with production that is typically aligned to ISO 9001 quality systems

- CE conformity and related regional approvals may apply depending on build and destination

- RoHS status varies by configuration; confirm per lot if required by your site

- Warranty support: 365 days standard

If you’re replacing a legacy governor board or stabilizing a genset that hunts under load, the Woodward 5448-906 is, in many cases, the quickest path to get your system back within spec—without redesigning the whole cabinet. If you can share your panel model, actuator type, and MPU details, we’ll double-check compatibility and pinout before shipping.

Reviews

There are no reviews yet.