Description

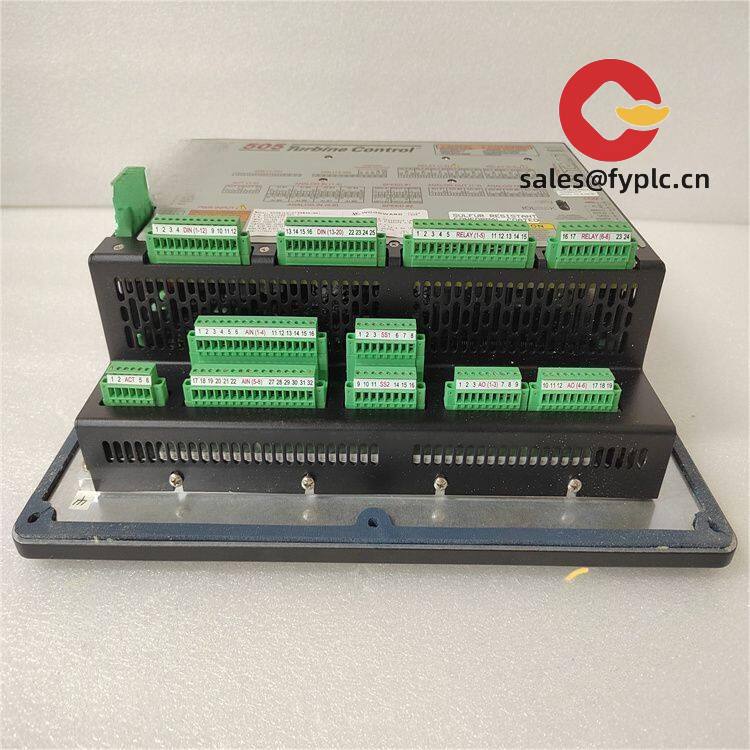

Woodward 8200-1301-505 – Replacement Control Module for 505-Series Turbine Governors

The Woodward 8200-1301-505 is a factory-grade module used within Woodward 505-series turbine control systems. In many cases it’s sourced as a like-for-like spare to recover a downed panel or to complete a scheduled upgrade without re-engineering the entire cabinet. From my experience, this part is typically specified to keep steam or gas turbine governor loops stable, with clean handover to the host 505 controller and the rest of the plant I/O.

Company’s Order Placement Process and Guarantees

- Warranty: 365 days coverage from delivery

- Lead time: 1 week if in stock; no more than one month at the latest

- Payment: 50% advance payment, full payment before delivery

- Express options: FedEx, UPS, DHL

Key Features

- Designed for 505-series systems – Built to slot into Woodward 505 turbine governors, helping maintain form-fit-function compatibility in existing cabinets.

- Industrial-grade build – Robust PCB and connectors suited for utility and oil & gas environments where uptime matters.

- Stable governor performance – Works with the host controller to keep speed and load control consistent across typical operating ranges.

- Service-friendly – Plug-in replacement approach reduces downtime; no need to redesign wiring in most cases.

- Traceable sourcing – Commonly used as a qualified spare for maintenance programs and outage kits.

Technical Specifications

| Brand / Model | Woodward 8200-1301-505 |

| Product Type | Control module for Woodward 505-series turbine controllers (spare/replacement) |

| HS Code | 9032.90 (Parts of automatic regulating or controlling instruments) |

| Power Requirements | 24 VDC nominal from the host 505 backplane (typical for this series) |

| Compatible System | Woodward 505-series turbine governors and related control panels |

| Signal I/O | Supports the standard I/O assignments used by 505 systems (discrete status/trip and process signals handled by host controller) |

| Communication | Communications managed by the main 505 controller (e.g., Modbus on host where configured) |

| Installation Method | Plug-in module; installs in the 505 controller chassis within a ventilated control cabinet |

Application Fields

You might notice that plants running legacy 505 panels keep one or two of these modules on the shelf. Typical sites include:

- Power generation – steam turbines, small gas turbines, and mechanical-drive units

- Oil & gas – compressor and pump trains requiring precise speed/load control

- Refining & petrochemical – process steam turbines with tight reliability requirements

- Pulp & paper, sugar mills – process turbines where scheduled outages are short

Feedback from one maintenance supervisor was straightforward: “We swapped the 8200-1301-505 during our weekend stop, powered back up, and the 505 came ready with no nuisance trips.” That’s typically the outcome you want on a Monday start.

Advantages & Value

- Risk reduction – Form-fit-function replacement minimizes commissioning risk and cuts downtime.

- Lifecycle support – Keeps established 505 cabinets serviceable without moving to a full DCS or controller retrofit.

- Cost control – Lower total cost vs. a wholesale control-system change, especially where wiring looms are already qualified.

- Compatibility – Matches 505 system interfaces and field termination, so no awkward rework during outages.

- Technical backing – Documentation and support typically align with standard Woodward 505 maintenance procedures.

Installation & Maintenance

- Cabinet environment – Install in a clean, dry, ventilated control cabinet. Maintain clearance for airflow and service access.

- Wiring practices – De-energize the panel, observe ESD precautions, and verify backplane connectors are fully seated before power-up.

- Grounding – Follow the 505 grounding scheme to avoid noise coupling into speed or process signals.

- Functional checks – After replacement, run speed/load simulations or permissive checks as required by site procedures.

- Routine care – Periodically inspect connectors for oxidation, keep the cabinet filters clean, and back up controller configuration files. Firmware updates, where applicable, should follow plant MOC protocols.

Quality & Certifications

- Manufacturer quality system: ISO 9001

- Conformity: CE marking (typical for Woodward control components)

- RoHS: Compliant in most cases for electronic assemblies

- Warranty: 365 days replacement/repair as stated above

If you’re coordinating an outage, we can align shipment with your lockout/tagout window and include any supporting items you might need—speed pickups, actuator spares, or terminal kits—so your team has everything on hand.

Reviews

There are no reviews yet.