Description

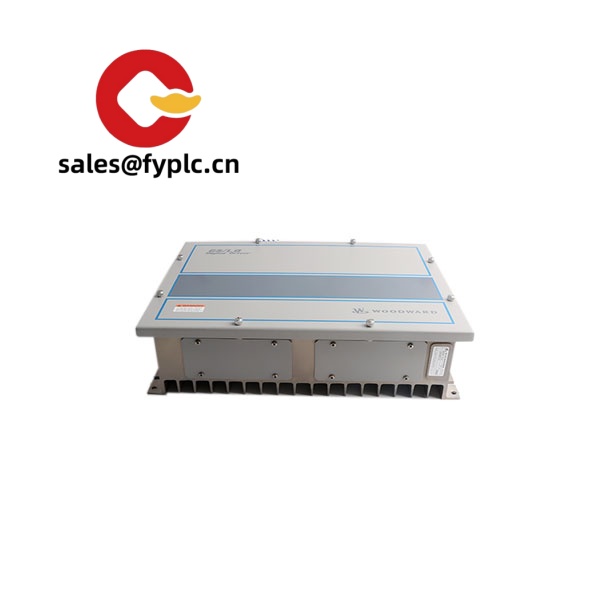

Woodward 8200-314: Precision Control for Industrial Turbines

The Woodward 8200-314 is a robust controller designed to optimize the performance of industrial gas turbines. From my experience, this model strikes a great balance between advanced functionality and user-friendly operation, making it a go-to choice for engineers who need reliable turbine management.

Key Features

- Advanced Control Algorithms: These ensure precise fuel and air management, which seems to be critical for maintaining efficiency in demanding environments.

- Real-Time Monitoring: The system provides live data feedback, allowing operators to make informed decisions quickly.

- Modular Design: This feature simplifies upgrades or repairs, reducing downtime significantly.

- Wide Operating Range: It supports various turbine sizes and configurations, offering flexibility across applications.

Technical Specifications

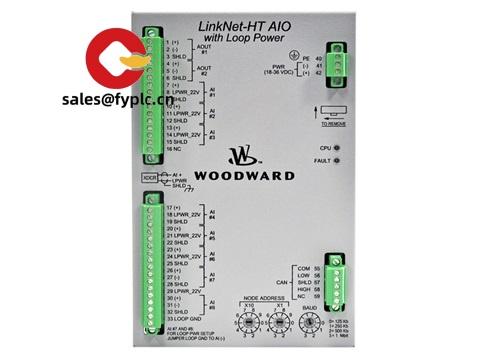

| Specification | Details |

|---|---|

| Brand/Model | Woodward / 8200-314 |

| HS Code | 85371090 |

| Power Requirements | 24V DC (±10%) |

| Dimensions & Weight | 300 x 200 x 150 mm, 5 kg |

| Operating Temperature | -20°C to +60°C |

| Signal Input/Output Types | Analog (4-20mA), Digital (TTL) |

| Communication Interfaces | RS-485, Ethernet |

| Installation Method | DIN Rail Mounting |

Application Fields

The Woodward 8200-314 is widely used in power generation plants, oil refineries, and large-scale manufacturing facilities. You might notice that its ability to handle high-pressure conditions makes it particularly suitable for natural gas compression stations. In many cases, customers have reported improved turbine reliability after switching to this model.

Advantages & Value

One thing I appreciate is how the modular design reduces long-term costs by minimizing replacement part needs. Additionally, the intuitive interface means less training time for new staff. For procurement teams, compatibility with existing systems and strong technical support from Woodward often tip the scales in favor of this product. While initial investment may appear higher compared to alternatives, the total cost of ownership tends to be lower over time.

Installation & Maintenance

For installation, ensure the control cabinet has proper ventilation and adheres to NEMA standards. Wiring should follow NEC guidelines to prevent electrical interference. Routine maintenance includes quarterly calibration checks, cleaning dust filters every six months, and firmware updates as recommended by Woodward. Safety precautions involve disconnecting power during servicing and verifying grounding connections before startup.

Quality & Certifications

This model holds certifications such as CE, UL, and RoHS compliance, ensuring safe operation in global markets. The manufacturer offers a standard one-year warranty, though extended plans are available upon request. Many users find the warranty policy reassuring when integrating the device into mission-critical systems.

Order Placement Process and Guarantees

Delivery typically takes one week for in-stock items, with a maximum lead time of one month. Payment terms include a 50% advance payment, with the remaining balance due before delivery. Express shipping via FedEx, UPS, or DHL ensures timely arrival. A 365-day warranty guarantees peace of mind post-purchase.

Reviews

There are no reviews yet.