Description

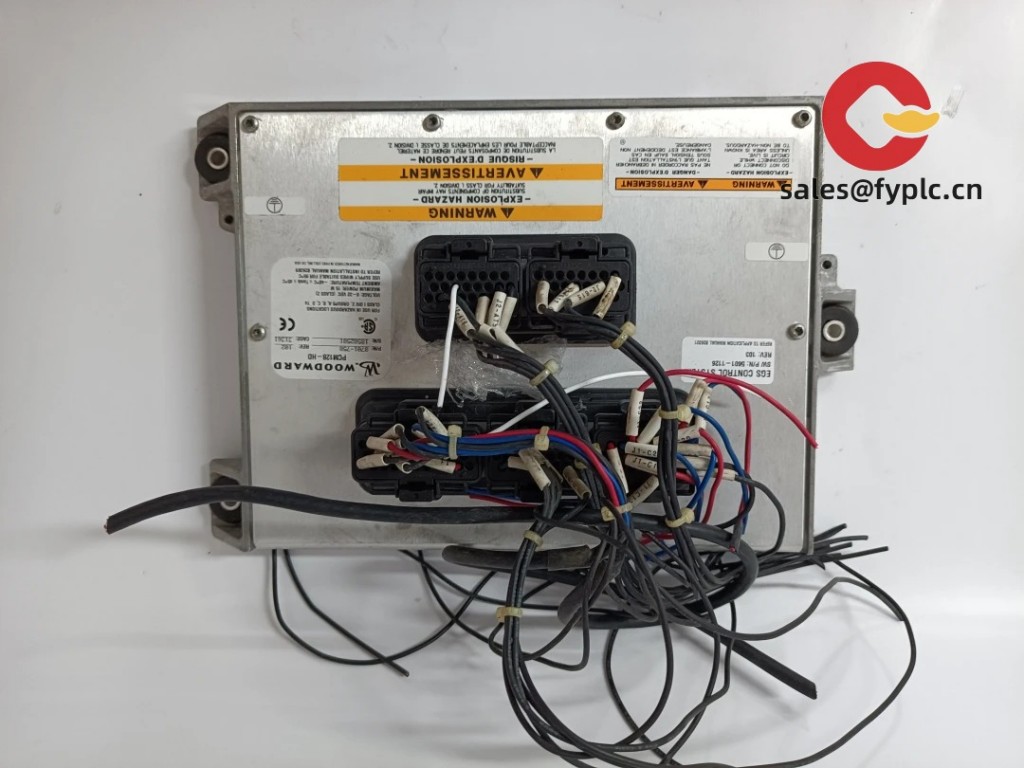

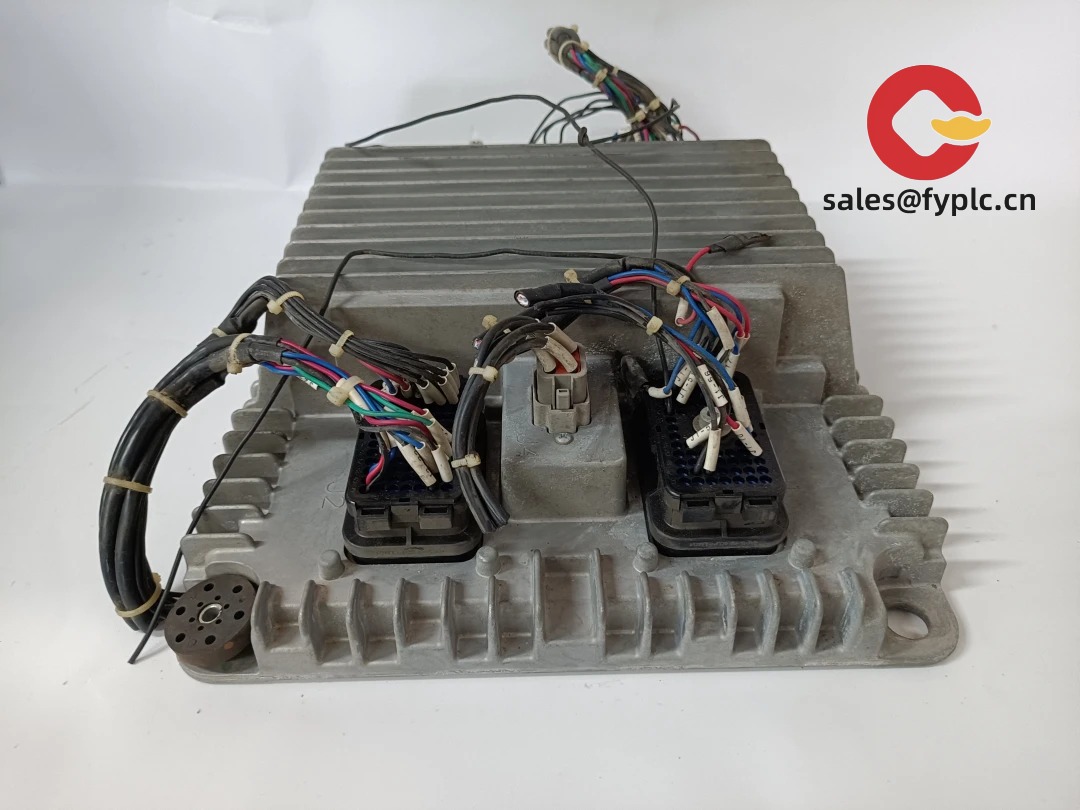

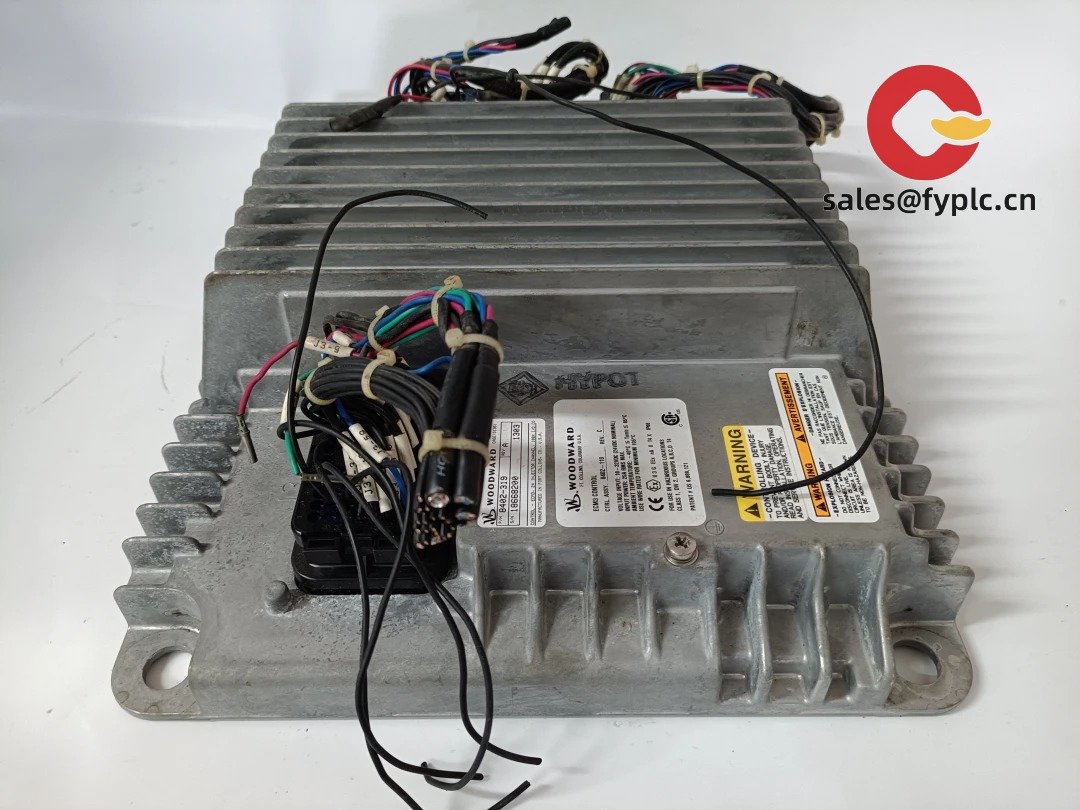

Woodward 8402-319 / 8402-119 Termination Assembly Set – Clean, reliable field wiring interface for MicroNet-based controls

The Woodward 8402-319 and 8402-119 are commonly paired as a termination assembly set that routes field signals to the matching rack module via a dedicated interface cable. From my experience, this kind of TA set is the unsung hero in turbine and compressor cabinets—clear labeling, robust terminals, and a direct, error‑resistant path from plant devices to the controller. You might notice project BOMs list both numbers together; it typically means you’re getting the board plus the correct cable or mating hardware, which saves time during panel build and FAT.

Company’s Order Placement Process and Guarantees

- Warranty period: 365 days

- Delivery time: 1 week for in‑stock items; no more than one month at the latest

- Payment terms: 50% advance payment; full payment for delivery

- Express delivery methods: FedEx, UPS, DHL

Key Features

- Purpose‑built field termination

– Presents orderly, labeled screw terminals for landing discrete and analog signals without ad‑hoc jumpers. - Direct module interface

– Uses the specified Woodward cable/mating connector to link straight to the rack I/O, reducing cross‑wiring mistakes. - Shield and earth management

– Provisions for shield bonding and clean grounding practices to minimize noise on low‑level signals. - Service-friendly layout

– Front‑access terminals and channel numbering make loop checks and proof tests faster in many cases. - Cabinet‑ready footprint

– Panel or bracket mounting for standard control cabinets; fits common wiring duct geometries. - Rugged hardware

– Industrial screw‑clamp terminals and sturdy connectors hold up well under vibration and frequent maintenance.

Technical Specifications

| Brand / Model | Woodward 8402-319 / 8402-119 (Termination Assembly Set) |

|---|---|

| HS Code | 853890 (Parts for electrical control panels / programmable controllers) |

| Power Requirements | Passive assembly; no separate power required in typical applications |

| Operating Temperature | Typically 0 to +60 °C, non‑condensing cabinet environment |

| Signal Input/Output Types | Field screw terminals to dedicated interface connector/cable for the matching Woodward rack module |

| Communication Interfaces | Passive TA‑to‑module cable; proprietary pinout matched to the corresponding I/O card |

| Installation Method | Panel/bracket mounting inside a control cabinet; front‑access terminal blocks and channel labels |

| Dimensions & Weight | Compact TA board format suitable for standard 600–800 mm cabinet depths (drawing available on request) |

Application Fields

This set is typically used wherever Woodward turbomachinery controls interface to hardwired plant signals. Practical use cases:

- Gas & steam turbine cabinets – landing limit switches, permissives, trips, and actuator feedback.

- Compressor anti‑surge and protection – organizing I/O for transmitters, valves, and shutdown paths.

- Generator sets – breaker status/control, sync permissives, and balance‑of‑plant signals.

- Refining / petrochemical / LNG – high channel‑count terminations in SIL‑applied architectures.

- Power & utilities – clean hand‑off to DCS/SIS via hardwired interfaces.

Advantages & Value

- Faster panel build – Predefined pinouts and labeled terminals typically cut wiring time and rework.

- Lower integration risk – Native fit to the matching Woodward I/O reduces cross‑termination errors.

- Maintainable layout – Clear channel numbering speeds loop checks, SAT, and proof testing.

- Noise‑aware design – Proper shield/earth provisions help keep low‑level signals clean.

- Spares strategy – Keeping like‑for‑like TA and cable sets on the shelf minimizes outage delays.

Installation & Maintenance

- Cabinet & routing – Mount on a flat, ventilated panel; allow bend radius for the interface cable and room for ferrules/markers.

- Wiring practices – Use ferruled conductors; separate low‑level I/O from power/VFD runs; bond shields per site grounding policy.

- Safety – Apply LOTO on field circuits; if the associated I/O is trip‑critical, follow site bypass rules before any work.

- Torque & inspection – Re‑torque terminals after initial heat cycles; check for insulation nicks and label legibility.

- Documentation – Keep the pinout/map with the cabinet file; it appears that this prevents mis‑patching during fast turnarounds.

Quality & Certifications

- Compliance – Typically used within CE‑compliant cabinet assemblies; RoHS‑conformant components are common.

- Use in SIL projects – Applied as part of Woodward architectures that support IEC 61508 SIL levels when engineered per the safety manual.

- Warranty – 365 days from delivery.

A commissioning engineer told me after a turbine outage, “Having the correct TA and cable pair meant every loop landed first‑time—no chasing cross‑wires.” That’s the everyday benefit these 8402‑319 / 8402‑119 sets tend to deliver.

Reviews

There are no reviews yet.