Description

Woodward 8407-515 Control Module – Stable speed and load control for engine/genset governor systems

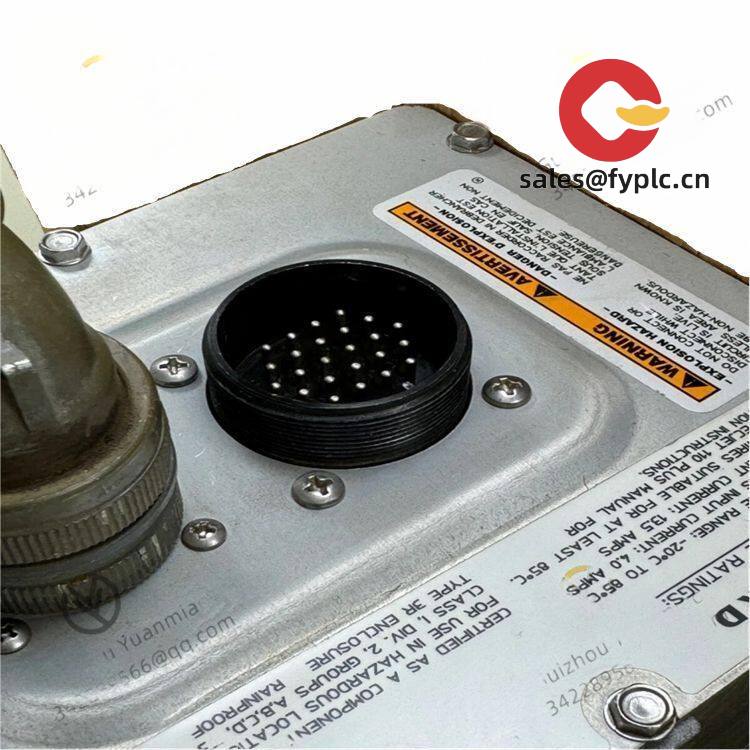

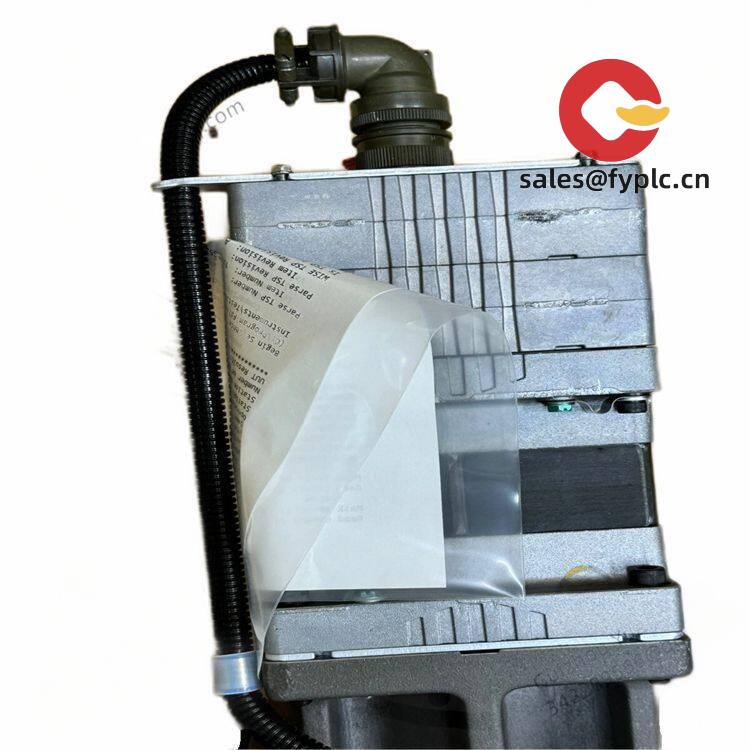

The Woodward 8407-515 is a factory original control module used in Woodward governor and speed-control systems for engines and generator sets. From my experience, it’s typically selected as a drop-in replacement to restore precise speed regulation, load sharing, and dependable start/stop logic without re-engineering the whole panel. You might notice that it plays nicely with standard magnetic pickups and actuator current drives, which keeps retrofit time short and predictable.

Order Placement Process and Guarantees

- Warranty: 365 days

- Delivery: 1 week if in stock; no more than one month at the latest

- Payment: 50% advance payment; full payment before delivery

- Express options: FedEx, UPS, DHL

Key Features

- Drop-in replacement – Designed to fit existing Woodward governor/control assemblies, minimizing panel changes and wiring rework.

- Stable speed regulation – Supports isochronous or droop-style behavior on engine/genset controls for steady operation under load.

- Load sharing compatibility – Works with typical Woodward load-sharing lines to balance kW across paralleled machines.

- Standard sensor & actuator I/O – Accepts magnetic pickup speed input and provides actuator current drive; simplifies field replacement.

- Robust industrial design – Built for continuous-duty environments common in power, oil & gas, and marine.

- Service-friendly – Clearly labeled terminals and trim points make site calibration faster, typically reducing downtime.

Technical Specifications

| Brand / Model | Woodward 8407-515 |

| HS Code | 903289 (Automatic regulating or controlling instruments) |

| Power Requirements | 24 VDC nominal (18–32 VDC typical for Woodward control modules) |

| Dimensions & Weight | Control-module form factor for panel/cabinet mounting; typically under 2 kg |

| Operating Temperature | –20 to +70 °C (typical range for Woodward engine/genset controls) |

| Signal Input/Output Types | Magnetic pickup speed input; 4–20 mA/analog speed or load reference; actuator current output; discrete relay/alarm contacts |

| Communication Interfaces | Analog load-sharing line; no native fieldbus on the base module (varies by system configuration) |

| Installation Method | Panel/cabinet mounting with screw-terminal wiring; shielded runs for sensor lines recommended |

Note: The above values reflect typical Woodward control module characteristics and field use. Exact values may vary by build revision; feel free to share your existing panel photos or nameplate details for a compatibility check.

Application Fields

- Diesel and gas generator sets requiring tight speed control and load sharing in parallel operation

- Industrial engines driving compressors, pumps, and blowers where steady rpm is critical

- Marine propulsion and auxiliary power systems needing robust governor performance

- Oil & gas facilities with aging panels looking for reliable OEM replacement modules

Advantages & Value

- Reliability in the field – These modules are known to run for years; a maintenance lead at a gas plant told me their 8407-515 swap brought a unit back online in under two hours.

- Compatibility first – Works with common Woodward magnetic pickups, actuators, and sharing lines, so you typically keep your existing sensors and wiring.

- Lower downtime costs – Straightforward commissioning and familiar trim adjustments reduce outage windows.

- Supportable long-term – Stable design philosophy; documentation and field-proven set-up procedures are widely used by technicians.

Installation & Maintenance

- Panel/cabinet environment – Mount in a clean, dry, ventilated enclosure; follow typical 19-inch or backplate panel practices with adequate clearance around heatsinks.

- Power & grounding – Use a regulated 24 VDC supply with proper earthing; segregate power and signal wiring to reduce noise.

- Sensor wiring – Shield magnetic pickup leads and route away from high-current conductors; maintain the correct pickup-to-gear gap.

- Actuator drive – Verify actuator coil current and linkage travel during commissioning; ensure no mechanical binding.

- Routine checks – Periodically verify speed setpoint, droop/isochronous settings, and sharing balance. Clean terminal areas and check for loose fasteners.

- Firmware/trim – If the build supports adjustable trims, document baseline settings before changes; update per service bulletins when applicable.

Quality & Certifications

- Manufactured by Woodward within ISO 9001 quality systems

- Typically CE-compliant for relevant EMC/safety directives

- UL recognition may apply to certain builds used in North America

- RoHS status varies by production year; many later builds meet RoHS requirements

- Standard warranty: 365 days

If you can share a photo of the existing nameplate and panel wiring, we can double-check compatibility and advise on the quickest installation approach. In many cases, it’s as simple as a direct swap, basic calibration, and a couple of test runs under load.

Reviews

There are no reviews yet.