Description

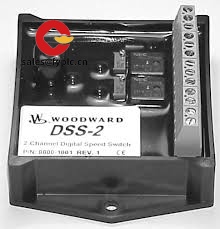

Woodward 8800-1001: Advanced Control for Industrial Turbines

The Woodward 8800-1001 is a powerhouse in turbine control systems, designed to ensure precision and reliability in demanding industrial environments. From my experience, this model seems to be one of the most sought-after solutions for operators looking to optimize performance while minimizing downtime.

Key Features

- High-Speed Processing: Equipped with a robust processor, it ensures real-time data handling, which is crucial for maintaining turbine stability.

- Modular Design: Its modular architecture allows for easy upgrades or replacements, saving both time and costs during maintenance.

- Fault Tolerant Operation: Built-in redundancy features help prevent system failures, ensuring continuous operation even under unexpected conditions.

- User-Friendly Interface: The intuitive HMI simplifies configuration and monitoring tasks, making it accessible even for less experienced operators.

Technical Specifications Table

| Specification | Details |

|---|---|

| Brand/Model | Woodward / 8800-1001 |

| HS Code | 85371099 |

| Power Requirements | 110-240V AC, 50/60Hz |

| Dimensions & Weight | 483 x 305 x 133 mm, 12 kg |

| Operating Temperature | -20°C to +60°C |

| Signal Input/Output Types | Analog (4-20mA), Digital (TTL) |

| Communication Interfaces | Ethernet, RS-485, Modbus RTU |

| Installation Method | Rack Mountable |

Application Fields

This controller typically finds its home in industries like power generation, oil and gas, and marine propulsion systems. For instance, you might notice that it’s often deployed in large-scale gas turbines where precise fuel-air ratio management is critical. It also works well in steam turbines requiring dynamic load adjustments. In many cases, customers report improved efficiency and reduced wear on mechanical components after integrating this unit into their systems.

Advantages & Value

One thing I appreciate about the Woodward 8800-1001 is how seamlessly it integrates with existing infrastructure, reducing compatibility headaches. Procurement teams will likely value its long-term cost savings due to minimal spare parts requirements and extensive technical support options. Additionally, its reputation for reliability means fewer unplanned outages, which can significantly impact operational budgets.

Installation & Maintenance

For installation, ensure your control cabinet meets standard NEMA 12 or IP54 ratings to protect against dust and water ingress. Proper ventilation is essential since heat dissipation can affect performance over time. Wiring should comply with local electrical codes, and calibration checks are recommended every six months. Firmware updates are occasionally released by the manufacturer, so keeping the software current helps maintain optimal functionality.

Quality & Certifications

Rest assured, the Woodward 8800-1001 comes with certifications including CE, UL, and RoHS compliance, ensuring safety and environmental responsibility. The manufacturer offers a 12-month warranty, though issues rarely arise given the product’s track record. If needed, replacement parts and technical assistance are readily available within days.

Order Placement Process and Guarantees: Delivery times vary depending on stock availability but typically range from one week for in-stock items to no more than a month for custom orders. Payment terms require a 50% advance payment, with the balance settled before shipment. Express delivery via FedEx, UPS, or DHL ensures prompt arrival at your facility.

Reviews

There are no reviews yet.