Description

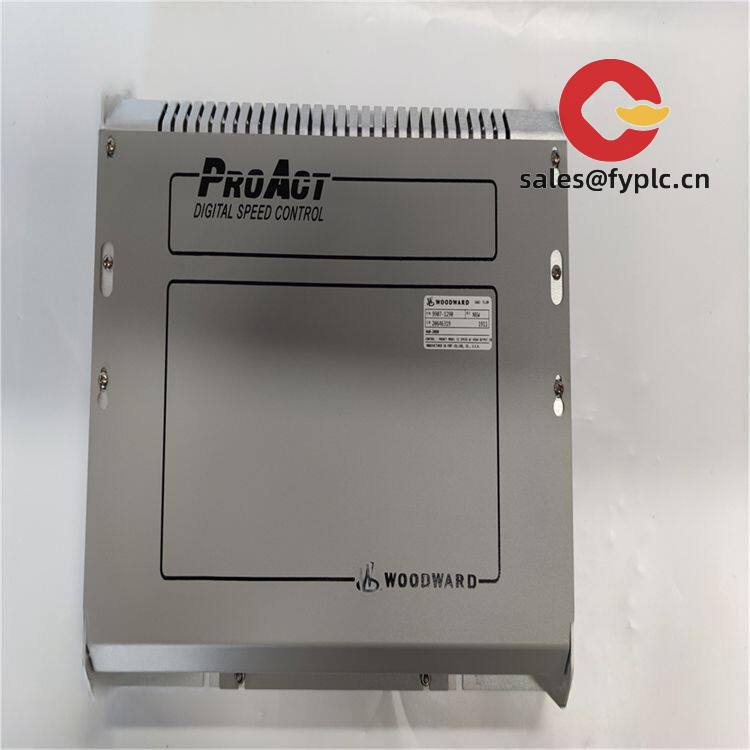

Woodward 9907-1290 Digital Speed Control – Precision Governing for Engines and Turbines

The Woodward 9907-1290 is a factory-numbered digital speed control designed for prime movers where stable, responsive governing really matters—diesel and gas engines on gensets, pumps, and compressors, and in many cases small steam or gas turbines. From my experience, this series typically delivers tight isochronous control, reliable droop for paralleling, and straightforward integration with Woodward actuators and standard magnetic speed pickups. You might notice that it feels purpose-built for retrofit work—modern control performance without forcing a complete panel redesign.

Order Placement Process and Guarantees

-

- – Warranty period: 365 days from delivery

-

- – Delivery time: 1 week if in stock; no more than one month at the latest

-

- – Payment: 50% advance; full payment prior to delivery

- – Express options: FedEx, UPS, DHL

Key Features

- Stable speed governing – Isochronous operation for constant speed and selectable droop for load sharing in paralleled systems.

- Flexible I/O set – Typically supports MPU speed pickup, analog control signals (e.g., 4–20 mA), and discrete inputs/relay outputs for permissives and alarms.

- Load sharing capability – Works with standard Woodward sharing schemes; ideal for multi-gen applications.

- Programmable response – PID and ramp/acceleration settings to match different engines, actuators, and process demands.

- Rugged design – Built for industrial cabinets; usually wide temperature tolerance and strong immunity to electrical noise.

- Service-friendly – From what users report, configuration is straightforward and repeatable, which reduces commissioning time.

Technical Specifications

| Brand / Model | Woodward 9907-1290 |

| Product Type | Digital speed control for engine/turbine governors |

| HS Code | 9032.89 (Other automatic regulating or controlling instruments) |

| Power Requirements | 24 VDC nominal (typically 18–32 VDC), < 25 W consumption in most cases |

| Operating Temperature | Typically -40 °C to +70 °C (cabinet-mounted industrial environment) |

| Signal Input / Output | MPU speed pickup; analog I/O (e.g., 4–20 mA command/feedback); discrete inputs; relay outputs for trip/alarms |

| Communication Interfaces | RS-485 (Modbus RTU) on many variants; local service/configuration port |

| Installation Method | Panel/chassis mounting inside a control cabinet; screw/plug-in terminal wiring |

| Dimensions & Weight | Compact panel-mount module; typically around 2–3 kg (confirm against the datasheet for your exact build) |

Application Fields

This unit is a good fit where dependable speed control and straightforward load sharing are expected:

- Gensets (diesel or gas) running in island mode or paralleled to bus

- Pumps and compressors needing steady-state speed with quick transient response

- Retrofit of legacy analog governors with a more configurable digital controller

- Small industrial steam/gas turbine packages that require isochronous control and protective I/O

Advantages & Value

- Reliability that operators trust – Woodward speed controls have a strong field record; fewer nuisance trips in harsh sites.

- Compatibility – Works with common Woodward actuators and MPUs; simplifies retrofit wiring and reduces downtime.

- Cost-effective integration – Modbus/analog options typically reduce the need for extra modules and gateways.

- Service support – Clear parameterization and stable firmware cut commissioning time and future service calls.

Installation & Maintenance

- Cabinet environment – Mount in a clean, dry control cabinet (IP54 or better recommended). Provide ventilation so the internal temperature stays within spec.

- Power and grounding – Use a clean 24 VDC supply with proper grounding and surge protection. Separate the control ground from power ground when practical.

- Wiring practices – Shielded twisted pair for MPU and analog runs; route low-level signals away from high-voltage conductors. Torque terminals to the manufacturer’s guidance.

- Commissioning – Set PID, ramps, and droop/isochronous modes per engine datasheet. Verify speed pickup gap and actuator calibration.

- Routine care – Periodically check terminal tightness, clean dust with dry air, review event logs, and apply firmware/config updates when available and validated.

- Safety – Lockout/tagout the prime mover; verify all trips and permissives before live testing. Keep a restore point of the working configuration.

Quality & Certifications

- Typically conforms to CE requirements for industrial control

- UL/cUL recognition is available on many Woodward controller variants

- RoHS alignment for electronic assemblies in most cases

- Manufacturer’s build and test processes are ISO-based; product-level certificates available on request

- Warranty: 365 days from delivery (our supply terms)

Related/Compatible Components (for fast project matching)

- Woodward actuators: EG-3P / EG-10P, ProAct series (model-dependent compatibility)

- Magnetic speed pickups (MPU) with standard thread sizes and typical 2–3 kΩ impedance

- Load sharing lines and Modbus RTU links for paralleled gensets

Reviews

There are no reviews yet.