Description

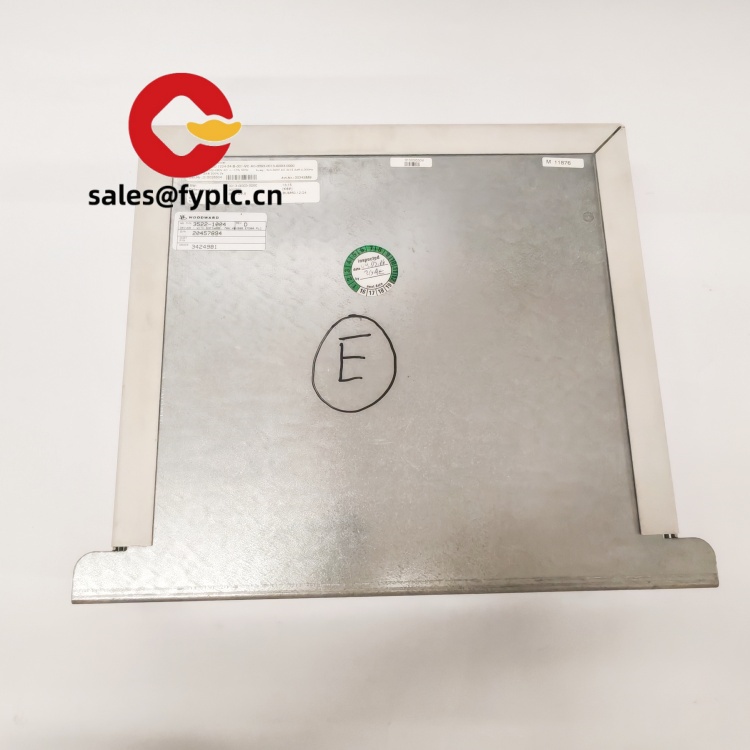

WOODWARD BUM60-1224-54-B-001-VC-A0-0093-0013-G003-0000 (P/N 3522-1004) – Configurable Control Module for 12/24 VDC Industrial Panels

This specific WOODWARD build code is a configurable control/auxiliary module designed for integration in engine, turbine, and power generation control cabinets. One thing I appreciate is the traceable build string—“1224” typically indicates 12–24 VDC operation, while option markers like “VC” often point to voltage conditioning or similar interface options. In many cases, modules with this code pairing are used as part of a larger Woodward system for reliable I/O interfacing, power distribution, and cabinet-level signal handling.

Order Placement Process and Guarantees

- Warranty: 365 days

- Lead time: 1 week if in stock; no more than 1 month at the latest

- Payment terms: 50% advance payment; full payment before delivery

- Express delivery: FedEx, UPS, DHL

Key Features

- Configured for 12/24 VDC cabinets: The “1224” code typically denotes compatibility with 12–24 VDC power systems found in genset and turbine panels.

- Industrial reliability: Built for continuous-duty environments with strong EMC immunity and stable operation in harsh conditions.

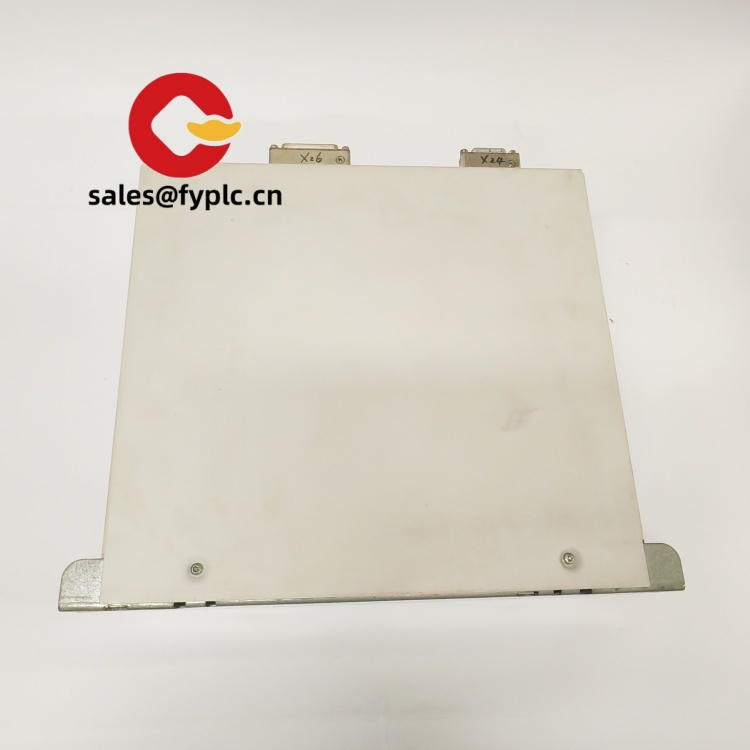

- Cabinet-friendly footprint: Compact module design that fits neatly into control panels; clean wiring through terminal connections.

- Option-based functionality: The “VC” option appears to indicate voltage conditioning or related I/O treatment; the full build string defines exact channel behavior.

- Traceable build code: Every segment of the code ensures BOM traceability for repeat orders and maintenance alignments.

- Woodward ecosystem compatibility: Typically paired with controllers like 2301E, easYgen, LS-5, and MicroNet systems depending on project architecture.

Technical Specifications

| Brand / Model | WOODWARD BUM60-1224-54-B-001-VC-A0-0093-0013-G003-0000 (Part No. 3522-1004) |

| HS Code | 8538.90 – Parts suitable for use with industrial control apparatus |

| Power Requirements | 12–24 VDC nominal (indicated by “1224” in the build code) |

| Signal I/O Types | Discrete/analog interfaces depending on options; “VC” typically implies voltage conditioning I/O |

| Communication Interfaces | Terminal-level I/O; no dedicated fieldbus indicated by this build string |

| Operating Temperature | Industrial range; typically -20°C to +70°C (project-specific confirmation recommended) |

| Installation Method | Panel/cabinet mounting; integrate in a ventilated, protected control enclosure |

| Dimensions & Weight | Compact auxiliary module; commonly < 0.5 kg. Exact outline per build drawing |

Application Fields

From my experience, units in this configuration are deployed in:

- Gas and steam turbine auxiliary panels (sensor/actuator interfacing and signal conditioning)

- Genset control cabinets (12/24 VDC distribution and discrete/analog I/O)

- Compressor and pump skids (robust signal handling in high-EMI environments)

- Balance-of-plant control panels in power and process industries

“We dropped this module into an existing Woodward cabinet on a gas compressor skid. Wiring went quickly, and the DC stability improved after moving our sensor lines through the VC-configured channels.” — Maintenance Lead, Midstream Operator

Advantages & Value

- Risk reduction: Exact build-code matching helps avoid integration surprises and rework.

- Lifecycle alignment: Consistent part numbering (3522-1004) supports spares planning across fleets.

- Cost control: Cabinet-ready design and straightforward terminals cut installation hours.

- Compatibility:</-strong> Plays nicely with Woodward controllers used across genset and turbine projects.

- Technical support: We can verify the build string against your controller firmware and I/O map before shipment.

Installation & Maintenance

- Cabinet environment: Install in a clean, dry, ventilated enclosure. Maintain clearance for wiring and heat dissipation.

- Power wiring: Use correctly rated DC supply (12/24 VDC), with proper grounding and overcurrent protection. Separate high-noise lines from low-level signals.

- Terminations: Tighten terminal screws to the recommended torque; label and route conductors to avoid crosstalk.

- EMC practice: Shield analog lines where needed; bond shields at a single point to reduce loops.

- Routine checks: Periodically inspect connectors, retighten terminals, and clean dust. Verify channel readings against known references.

- Firmware/config (if applicable): If the system includes firmware-configurable parameters, align module options with the controller’s I/O map and keep revision notes.

- Safety: De-energize circuits before servicing; follow lockout/tagout procedures and ESD precautions.

Quality & Certifications

- Certifications: Typically CE compliant; UL/cUL and RoHS status depend on the exact build. We can confirm per 3522-1004 prior to order.

- Manufacturer warranty: Woodward provides standard coverage; our supply includes a 365-day warranty period.

- Traceability: Full build code and serial tracking supplied on documentation and labels.

Supporting Components (Common Pairings)

- WOODWARD 2301E or easYgen series controllers for genset/turbine control

- WOODWARD LS-5 for breaker control and synchronization

- Speed sensors and pickups (e.g., magnetic pickups) matched to your prime mover

- WOODWARD actuators (e.g., ProAct series) and relevant I/O harnessing

You might notice that each segment of the BUM60 build code defines a specific performance or interface option. If you share your controller model and cabinet drawing, we can validate that this exact unit—BUM60-1224-54-B-001-VC-A0-0093-0013-G003-0000 (3522-1004)—matches your I/O expectations and approvals before shipping. That tends to save time during commissioning.

Reviews

There are no reviews yet.