Description

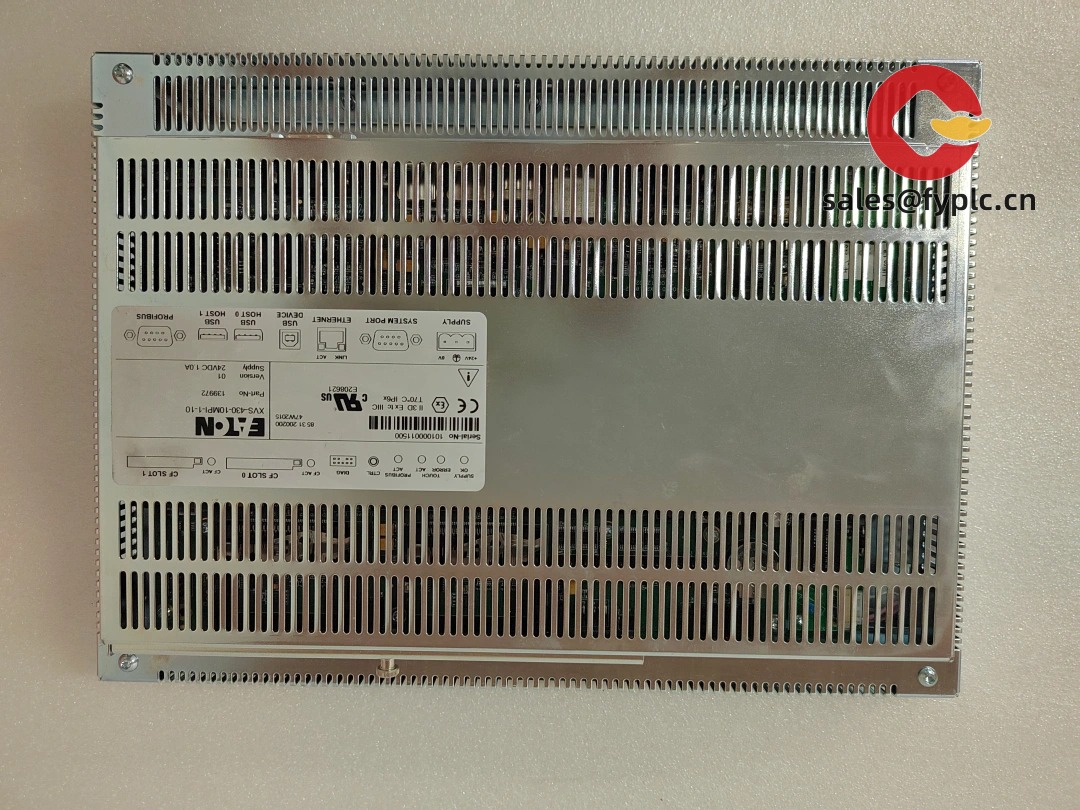

XVS-430-10MPI-1-10 – 4.3-inch HMI panel for Siemens S7 MPI connectivity

The XVS-430-10MPI-1-10 is a compact operator panel that, in many cases, is chosen for direct communication with Siemens S7-300/400 controllers over MPI. From my experience, engineers pick this size when they need clear visualization, quick commissioning, and trouble-free retrofits into existing MPI networks. You might notice that the model code hints at a 4.3-inch display and an onboard MPI port, which typically makes it a neat drop-in for older machines where PROFIBUS/MPI is still the backbone.

Company’s Order Placement Process and Guarantees

- Warranty: 365 days

- Delivery: 1 week for in-stock; no more than one month at the latest

- Payment: 50% advance payment; full payment before delivery

- Express delivery: FedEx, UPS, DHL

Key Features

- Native MPI connectivity – Designed for direct communication to S7-300/400 via MPI, which typically simplifies legacy upgrades and keeps cabling straightforward.

- 4.3-inch color touchscreen – A practical format for compact machines; operators get clear alarms, setpoints, and diagnostics without consuming panel space.

- 24 VDC industrial power – Standard cabinet supply with tolerance for typical shop-floor conditions.

- Panel-mount with IP65 front (when correctly gasketed) – Helps resist dust and incidental splashes at the operator interface.

- Serial ports for multi-protocol use – In many cases supports Modbus RTU (RS-485) alongside the MPI port, handy for secondary devices like inverters or meters.

- Service-friendly project download – Usually supports USB download so maintenance teams can update screens or recipes quickly.

Technical Specifications

| Brand/Model | XVS-430-10MPI-1-10 |

| HS Code | 853710 (Programmable control/display equipment for industrial control) |

| Power Requirements | 24 VDC nominal (typically 10.8–28.8 VDC) |

| Display | 4.3-inch TFT color touchscreen; common resolution: 480 × 272 (typical for this size) |

| Operating Temperature | 0 to +50 °C (typical) |

| Signal Input/Output Types | 1 × MPI (DB9); 1 × serial (RS-232/RS-485, model-dependent); no onboard discrete I/O in most cases |

| Communication Interfaces | MPI for S7-300/400; commonly supports Modbus RTU on RS-485; USB device for programming (typical) |

| Ingress Protection (front) | IP65 when panel-mounted with gasket (typical) |

| Dimensions & Weight | Approx. 128 × 102 × 40 mm; ~0.35 kg (typical for 4.3-inch HMIs) |

| Installation Method | Panel-mount with rear clamps; recommended steel cabinet door with proper gasket compression |

Application Fields

This model is typically used on legacy and mixed-technology lines where Siemens S7-300/400 are present:

- Packaging and labeling machines needing a compact MPI operator station

- Conveyors and materials handling where space is tight but diagnostics must be visible

- HVAC and utilities inside industrial campuses running S7-300-based controls

- Water and wastewater skids with S7 networks and basic HMI visualization

- Machine tools and retrofits where keeping MPI simplifies change management

Advantages & Value

- Reduced integration effort – Direct MPI support means less time reworking networks or replacing PLC communication cards.

- Space-saving design – The 4.3-inch format fits crowded doors while still presenting alarms, trends, and setpoints clearly.

- Lifecycle-friendly for brownfield sites – From my experience, plants with S7-300/400 appreciate HMIs that “just speak” MPI without extra gateways.

- Cost control – Typically lower total cost vs. upgrading entire networks to Ethernet when a small HMI is all that’s needed.

- Serviceability – USB project download and standard 24 VDC power simplify maintenance for on-site technicians.

Installation & Maintenance

- Panel mounting – Cut the recommended opening and ensure gasket compression for IP65 at the front. Avoid torsion on the bezel by evenly tightening clamps.

- Power & wiring – Use a clean 24 VDC supply with proper grounding. For MPI, use shielded DB9 cabling and maintain end-of-line termination on the final node.

- Cabinet environment – Provide ventilation; keep ambient 0–50 °C and relative humidity within spec. Separate signal and power wiring to reduce noise.

- Safety – De-energize before wiring; verify PLC network address and baud before commissioning to avoid bus conflicts.

- Routine maintenance – Back up the HMI project after any edits, clean the touchscreen with a soft lint-free cloth, and, where applicable, keep firmware and configuration tools up to date.

Quality & Certifications

- CE and RoHS compliance are typically available for this class of HMI; UL/cUL may be available depending on batch and region.

- Manufacturer’s warranty: 12 months (365 days) as provided above.

Recommended Supporting Components

- MPI cable (DB9, shielded) – 1.5–3 m lengths are common for panel-to-PLC runs; ensure proper shielding and ferrules for cabinet entry.

- 24 VDC DIN-rail power supply (60–90 W) – Provides clean power headroom for the HMI and small peripheral loads.

- Panel-mount gasket and clamp kit – To maintain IP65 at the front after maintenance cycles.

- USB programming cable/device – For quick project download and backup on site.

Quick customer note: A packaging OEM recently swapped a failing 5.7-inch unit to the XVS-430-10MPI-1-10 and, interestingly, operators preferred the smaller screen because it fit better next to the E-stop and key switch. Commissioning was under one shift since the MPI node mirrored the prior HMI’s addressing.

Reviews

There are no reviews yet.