Description

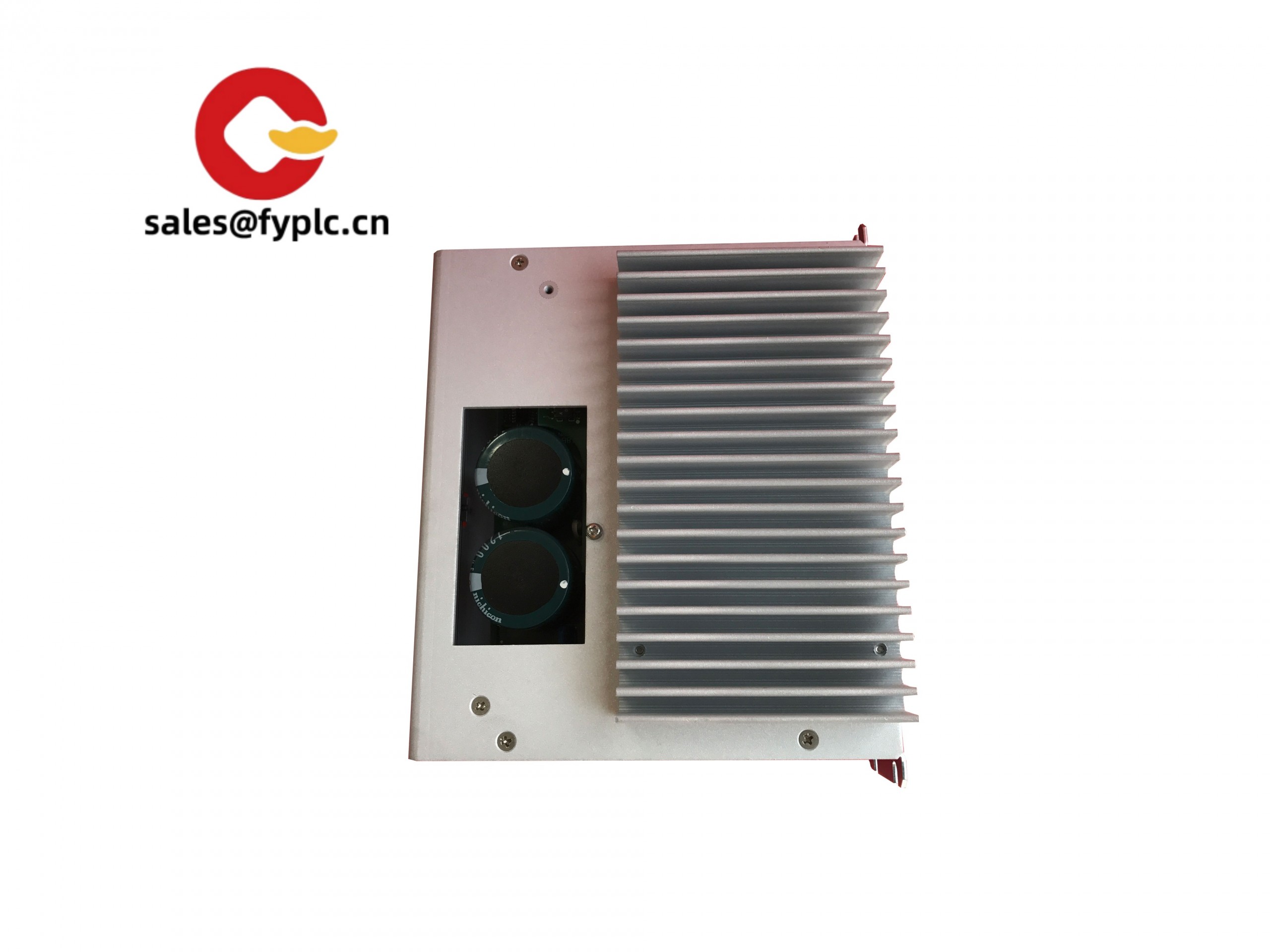

Yaskawa CACR-02-KIBA ServoPack – 200 V-class servo drive for compact 0.2 kW motion

The Yaskawa CACR-02-KIBA is a classic 200 V-class ServoPack that typically pairs with 0.2 kW AC servomotors in legacy and retrofit equipment. From my experience, it’s favored for drop-in replacements on older packaging lines, light pick-and-place axes, indexing tables, and feeders where stable analog control and quick commissioning matter more than modern fieldbus features. One thing I appreciate is the straightforward I/O and ±10 V command structure—it makes troubleshooting predictable, and maintenance teams can usually get a machine back up in minutes rather than hours.

Order Placement Process and Guarantees

- Warranty: 365 days

- Lead time: 1 week if in stock; no more than one month at the latest

- Payment terms: 50% advance payment, full payment before delivery

- Express options: FedEx, UPS, DHL

Key Features

- 0.2 kW class, 200–230 V operation – Suits small axes where precise torque and speed are needed without oversizing the drive.

- Analog ±10 V command – Simple torque/velocity control from PLC/IPC cards; easy to tune on retrofit projects.

- Pulse train position input – In many cases supports open-collector or line-driver pulses for indexing and point-to-point moves.

- Incremental encoder feedback – Works with Yaskawa 200 V servomotors of the same era (e.g., SGM/SGMP series), using A/B/Z signals.

- Built-in protections – Overcurrent, overvoltage, undervoltage, and thermal alarms to safeguard motor and drive.

- Panel-mounted design – Vertical mounting in a ventilated cabinet; service access to CN connectors keeps swaps quick.

Technical Specifications

| Brand / Model | Yaskawa CACR-02-KIBA |

|---|---|

| HS Code | 8504.40 (Static converters, servo drive) |

| Power Requirements | 200–230 VAC, 50/60 Hz, single-phase input; 0.2 kW (200 W) class motor capacity |

| Dimensions & Weight | Approx. 260(H) × 90(W) × 180(D) mm; around 2.5–3.0 kg (varies slightly by sub-variant) |

| Operating Temperature | 0 to 45 °C; non-condensing environment recommended |

| Signal Input/Output Types | Analog ±10 V (torque/velocity), pulse train for position, digital I/O (Servo ON/Ready/Alarm), incremental encoder A/B/Z feedback |

| Communication Interfaces | CN terminal connectors for command I/O and encoder; no fieldbus on this legacy variant |

| Installation Method | Panel/cabinet vertical mounting; forced-air cooling with top/bottom clearance |

Application Fields

This model appears frequently in compact axes for packaging, electronics assembly, labeling, light conveyance, and test fixtures. You might notice that many maintenance teams choose the CACR-02-KIBA for like-for-like replacements in legacy machines because wiring and commands match their existing PLC analog cards and pulse outputs. It also works well on retrofit projects where a modern fieldbus isn’t mandatory but cycle-time stability still matters.

Advantages & Value for Procurement

- Reliability – Proven ServoPack platform; stable operation under typical factory conditions.

- Compatibility – Designed for 200 V Yaskawa servomotors (e.g., SGM/SGMP of corresponding capacity) with incremental encoders.

- Reduced downtime – Familiar terminals and parameters let technicians swap units quickly. A maintenance lead at a food-packaging site told me they were running production within an hour after replacement.

- Cost-effective retrofit – Keeps the existing analog PLC architecture; no need to re-engineer control panels.

- Support & spares – We can supply matching power/encoder cables and, in many cases, the proper regenerative resistor unit for safe deceleration.

Installation & Maintenance

- Cabinet standards – Mount in a clean, dry control cabinet with adequate ventilation; observe vertical mounting and top/bottom clearances for airflow.

- Wiring – Use shielded cables for encoder and analog command lines; separate power and signal routes to minimize noise. Ground per manufacturer guidelines.

- Braking/regen – For fast stops or high-inertia loads, include a suitable regenerative resistor sized to the axis duty. This is often essential on short-cycle packaging axes.

- Safety – Isolate mains, discharge DC bus before service, and verify lockout/tagout. Confirm motor parameters before enabling torque.

- Routine checks – Inspect fans and vents quarterly, verify terminal tightness, clean dust using dry air, and back up parameters after tuning. Firmware updates are not typical on this legacy platform.

Quality & Certifications

Yaskawa Servopacks of this series are typically CE marked and UL Recognized when used with compliant accessories and installation practices. RoHS applicability may vary for legacy units; we can confirm compliance on a per-lot basis. Standard manufacturer warranty on supplied units is 365 days through us.

Compatible Components & Accessories

- Yaskawa 200 V servomotors in the 0.2 kW range (e.g., SGM / SGMP series) with incremental encoders

- Matching power and encoder cables (CN connectors)

- Regenerative resistor assemblies sized to duty cycle

- Panel accessories: line reactor, EMI filter, circuit protection, and proper grounding busbars for noise-sensitive installations

Reviews

There are no reviews yet.