Description

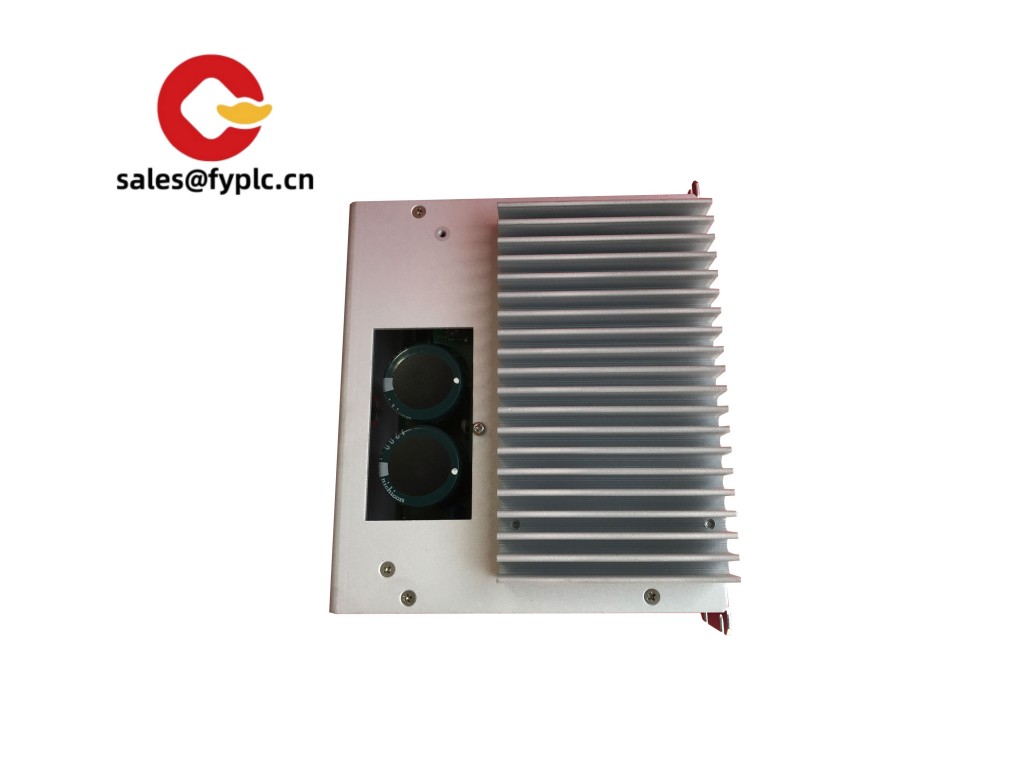

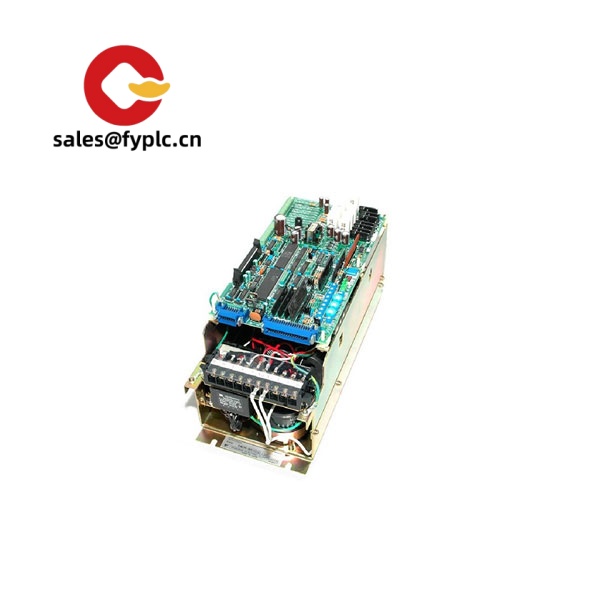

Yaskawa CACR-SR03BB1HS Servopack – Compact 200 V-class AC servo drive for precise, analog-controlled motion

The Yaskawa CACR-SR03BB1HS belongs to the proven CACR-SR Servopack family, widely used on packaging lines, printing machines, and legacy CNC axes where a stable analog command and dependable speed/torque response are required. From my experience, this unit is a go-to when you need a drop-in replacement that preserves existing ±10 V command schemes and standard I/O without rewriting your PLC or motion program. It seems to be most comfortable driving small-to-medium 200 V-class servomotors, delivering quick response and clean velocity control in many cases.

One thing I appreciate is how predictable the tuning feels on these SR-series amplifiers—gain and compensation pots make on-site touch-ups straightforward, and the alarm signaling is simple to integrate with older control cabinets. If you’re stabilizing an axis on a retrofit or keeping a mature machine productive, this model typically saves hours of redesign.

Company’s Order Placement Process and Guarantees

- Warranty: 365 days

- Lead time: 1 week if in stock; no more than one month at the latest

- Payment: 50% advance payment; full payment prior to delivery

- Express delivery: FedEx, UPS, DHL

Key Features

- Analog command (±10 V) – Ideal for legacy PLC and motion controller interfaces; quick to integrate without reprogramming.

- Stable speed/torque control – Fast response and smooth low-speed behavior suited to feeders, winders, and indexing axes.

- Encoder feedback compatibility – Works with Yaskawa pulse coder (incremental) feedback on matching servomotors; resolver support exists on certain variants.

- Clear alarms and discrete I/O – Standard “Servo ON/Ready/Alarm” signals simplify cabinet wiring and diagnostics.

- 200 V-class operation – Typically installed on 200–230 VAC systems; common in Asian and EU panels.

- Panel-mount design – Compact Servopack footprint for dense control enclosures.

- Protection functions – Overcurrent, over/undervoltage, and overheat protection to safeguard drive and motor.

Technical Specifications

| Brand / Model | Yaskawa CACR-SR03BB1HS |

| HS Code | 8504.40 (Static converters – servo drive category) |

| Power Requirements | AC 200–230 V, 50/60 Hz (200 V-class; in most cabinets wired as 3‑phase) |

| Operating Temperature | 0 to 45 °C (non-condensing, typical panel environment) |

| Signal I/O Types | Analog speed/torque command ±10 V; discrete I/O (Servo ON, Ready, Alarm, torque limit); encoder feedback (incremental Yaskawa pulse coder) |

| Communication Interfaces | No fieldbus; hardwired analog/discrete signals (typical for CACR-SR) |

| Installation Method | Panel/cabinet mount, vertical orientation with front access; forced-air clearance top and bottom |

Application Fields

You might notice this model showing up in retrofit and life-extension projects where the control strategy is already proven. Typical applications include:

- Packaging machinery: film feeders, sealing jaws, and labeling axes using analog velocity loops

- Printing and converting: web tension, unwind/rewind, and register control

- CNC and machine tools: auxiliary axes, spindles with analog speed control

- Electronics assembly: pick-and-place feeders and conveyors

- Textile and wire processing: constant torque winders and pay-off systems

“We swapped in a CACR-SR03BB1HS on a mid-90s wrapper, kept the ±10 V loop intact, and the line was back up same day.” — Maintenance Supervisor, Food Packaging

Advantages & Value

- Reliability – CACR-SR units are known for robust protection and long service life in 24/7 duty.

- Compatibility – Keeps legacy analog control schemes; no need for new fieldbus cards or PLC code changes.

- Cost saving – In many cases, a like-for-like replacement avoids a full drive/motor/platform migration.

- Technical support – Parameter cross-reference and wiring guidance help reduce commissioning time.

Installation & Maintenance

- Cabinet standards – Mount vertically on a rigid backplate. Allow ventilation space above and below; avoid heat sources directly beneath.

- Power & grounding – Use a dedicated 200–230 VAC supply with proper grounding. A line reactor and EMI filter are advisable in noise-heavy plants.

- Wiring – Shielded command/feedback cables, separated from motor power. Keep encoder and analog lines away from contactor and VFD cables.

- Tuning – Start with conservative gains; adjust velocity/torque loops via front-panel pots. Many technicians prefer a light load check before full speed.

- Routine maintenance – Quarterly dust cleaning, terminal re-torque checks, and fan/air path inspection. Electrolytic capacitors on older units benefit from periodic health checks.

Quality & Certifications

- Manufacturer certifications typically include CE and UL/cUL for relevant series generations

- RoHS compliance may vary by production year for CACR-SR models

- Warranty: 12 months (365 days)

Compatible Accessories & Supporting Components

- Yaskawa 200 V-class servomotors from the same era (e.g., S-series/SGM-series with pulse coder feedback)

- Motor power and encoder/pulse-coder cables matched to motor model and cable length

- External regenerative resistor (when required by duty cycle), line reactor, and EMI/RFI filters

- Panel cooling fans and filtered vents to maintain stable internal temperatures

If you’re replacing an existing CACR-SR unit, sharing the motor model and any available parameter sheet typically speeds up a smooth, first-try startup.

Reviews

There are no reviews yet.