Description

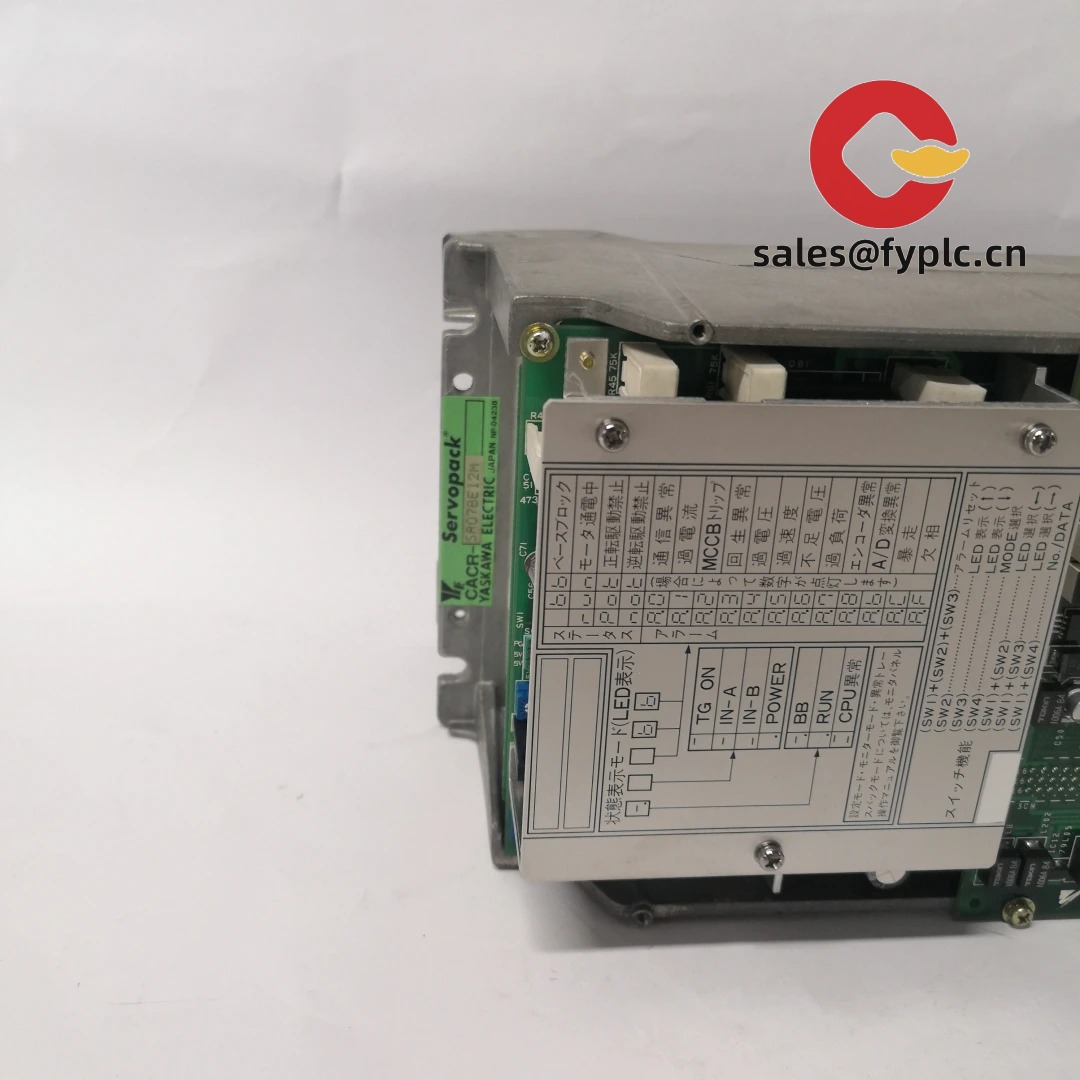

YASKAWA CACR-SR07BE12M AC Servopack – Stable, analog-controlled servo drive for legacy and mid-life machinery

The YASKAWA CACR-SR07BE12M is part of the CACR-SR Servopack family, a proven AC servo drive series that many OEMs still rely on for dependable torque and speed control. One thing I appreciate is how predictable these units behave with classic ±10 V analog command systems—ideal when you’re keeping an existing machine running without rewriting the whole control philosophy. In many cases, it pairs with Yaskawa AC servo motors of the same capacity class and supports incremental encoder feedback through the motor feedback loop. If you’re maintaining legacy machine tools, packaging equipment, or older lines where downtime hurts, this model tends to be a safe bet.

Order Placement Process and Guarantees

- Warranty: 365 days

- Lead time: 1 week if in stock; no more than one month at the latest

- Payment: 50% advance payment; full payment prior to delivery

- Express options: FedEx, UPS, DHL

Key Features

- Analog command interface (±10 V): Simple speed/torque command input, ideal for retrofits and legacy PLC/CNC control.

- Stable velocity/torque control: Typically smooth response with incremental encoder feedback from compatible Yaskawa motors.

- 200 V class operation: Matches many Japan/Asia-standard 200–230 V systems used on classic equipment.

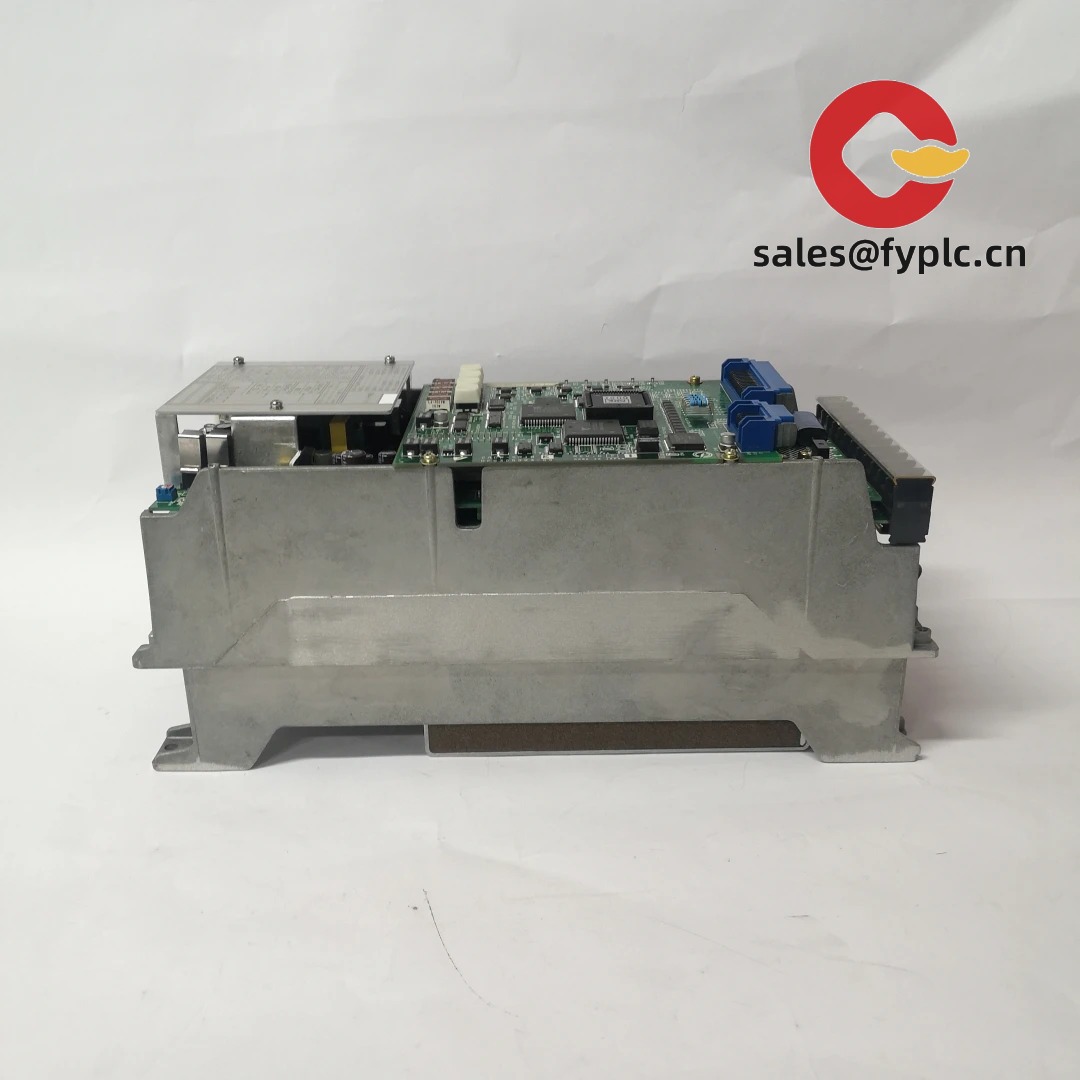

- Panel-mounted design: Straightforward installation inside an industrial cabinet with standard grounding practices.

- Serviceable for long life: From my experience, routine fan and capacitor checks go a long way on these drives.

- Good spare-part availability: Common across older machine tools and packaging/printing lines, which eases maintenance planning.

Technical Specifications

| Brand / Model | YASKAWA CACR-SR07BE12M (CACR-SR series AC Servopack) |

| HS Code | 850440 (Static converters, includes AC servo drives) |

| Power Requirements | AC 200–230 V class, 50/60 Hz (typical for CACR-SR series) |

| Operating Temperature | 0 to 45 °C (commonly specified for this generation) |

| Signal Input / Output Types | Analog speed/torque command ±10 V; digital I/O for Servo ON/Alarm/Ready; incremental encoder feedback from motor (typical) |

| Communication Interfaces | Terminal-level I/O (no fieldbus on most CACR-SR models) |

| Installation Method | Panel/cabinet mounting; vertical orientation with clearance for airflow |

Application Fields

The CACR-SR07BE12M is commonly used where reliable speed or torque control is needed without complex fieldbus integration. You might notice that it fits particularly well in:

- Machine tools (retrofit spindles, axis drives on classic CNCs)

- Packaging and converting lines (feed rollers, unwind/rewind, flying knife actuators)

- Printing and labeling equipment (register control, web handling)

- Assembly fixtures and handling systems (pick-and-place, index tables)

- Testing stations or lab rigs where analog control is standard

Advantages & Value

- Reliability: These drives are known for steady performance; downtimes are typically due to age-related components and are predictable to plan around.

- Compatibility: Works smoothly with analog PLC/CNC systems and existing I/O—saves re-engineering cost.

- Cost control: For legacy machines, replacing like-for-like often avoids the hidden expenses of a full motion platform change.

- Technical support: We assist with parameter checks, wiring advice, and commissioning tips to shorten your restart time.

Installation & Maintenance

- Cabinet requirements: Mount vertically in a ventilated enclosure (IEC/UL-rated). Keep adequate top/bottom clearance for airflow.

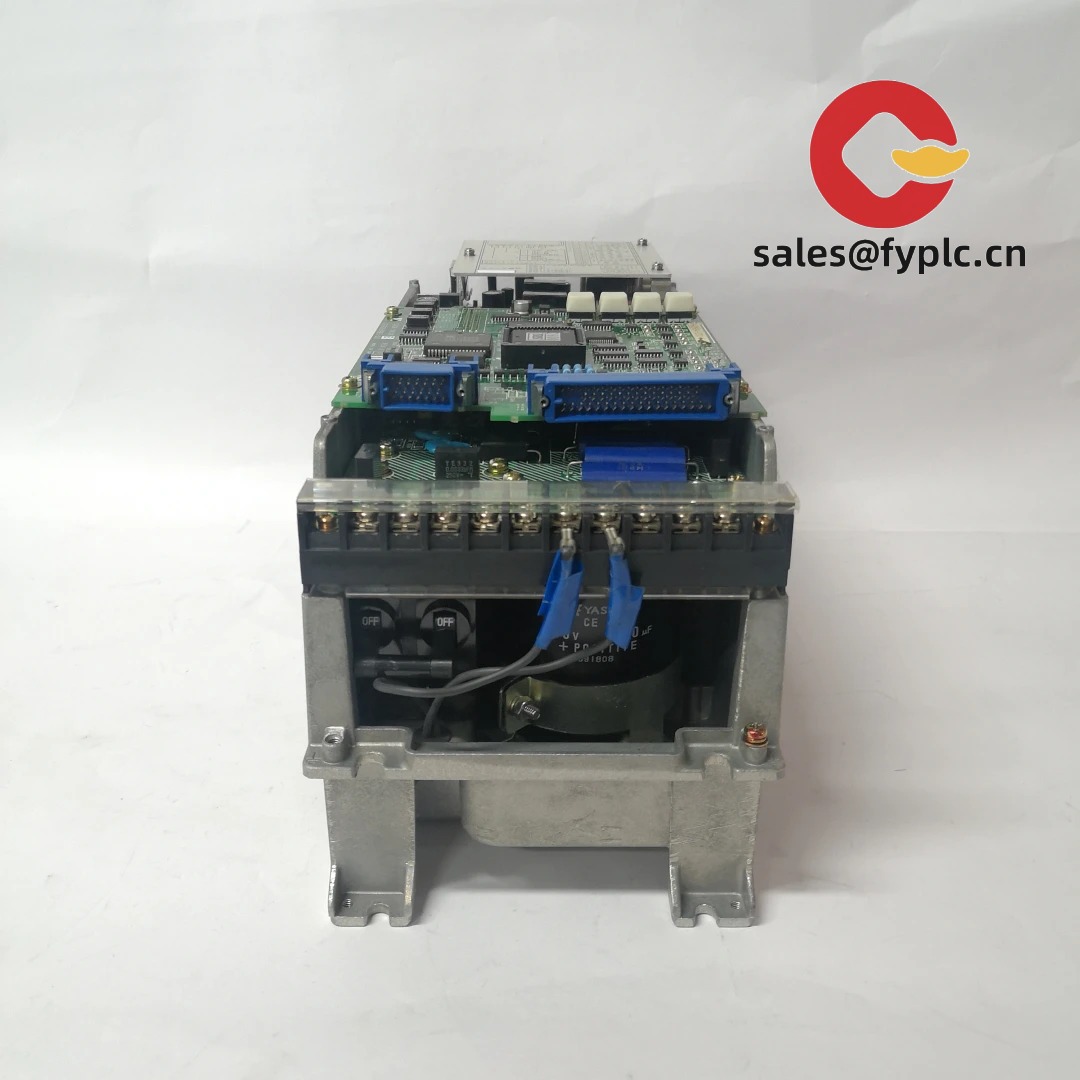

- Power and grounding: Use a dedicated AC 200–230 V source with proper grounding. Separate motor power from signal cabling to reduce noise.

- Wiring practice: Shielded twisted-pair for analog command and encoder lines; bond shields at the drive end. Check brake resistor sizing if used.

- Safety: Lockout-tagout before servicing. Confirm motor phases and rotation; verify Servo ON interlocks and E-Stop logic.

- Routine maintenance: Clean dust filters and heat sinks quarterly in dusty plants. Inspect fans and electrolytic capacitors; replace if noise/heat rises.

- Parameter backup: Record key parameters after commissioning. On older units, keeping a hard copy on the panel door seems to be the most foolproof.

Quality & Certifications

- Certifications: Many CACR-SR units were CE and UL marked for their market at the time; manufacturing aligned with ISO 9001 practices.

- Environmental compliance: RoHS may not apply to early production years—confirm per batch if this matters for your site policy.

- Warranty: 365-day warranty coverage on the unit provided.

Recommended Supporting Components

To streamline installation, we can supply matched accessories that typically accompany CACR-SR drives:

- Compatible Yaskawa AC servo motor (matching the SR07 capacity class)

- Motor power cable and encoder/feedback cable sets (shielded)

- External braking resistor (if your duty cycle requires faster deceleration)

- Line reactor or EMI filter for noise-sensitive cabinets

- Panel hardware: grounding bus, ferrules, cable glands for tidy routing

A Quick Note from the Field

A packaging customer swapped a failing legacy unit for a CACR-SR07BE12M and kept their original ±10 V control scheme. Start-up took half a day—most of it verifying I/O polarity and encoder wiring—and they were back at rate without changing the PLC code. That’s typically the kind of low-friction result these units are known for.

Reviews

There are no reviews yet.