Description

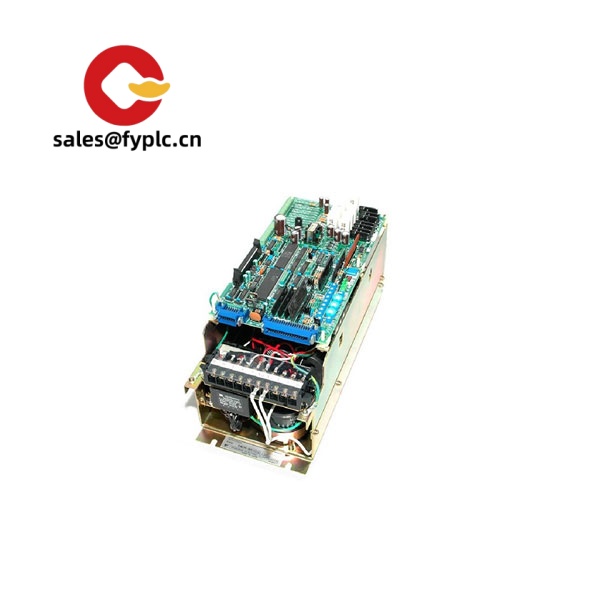

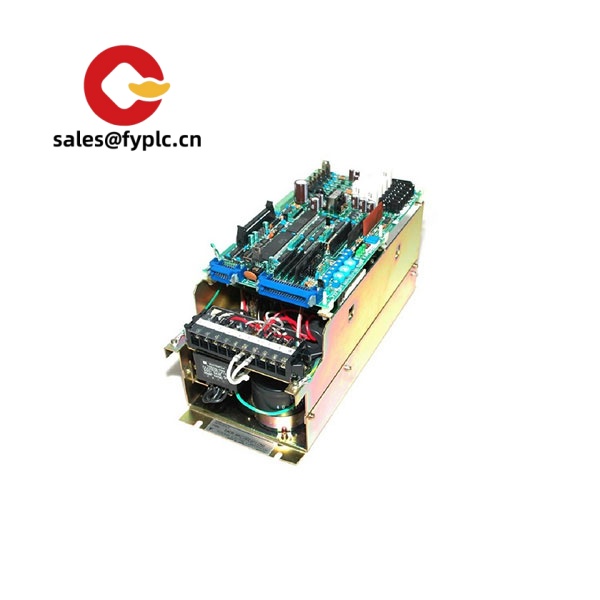

Yaskawa CACR-SR10BB1BF AC Servo Drive – Reliable SERVOPACK for Legacy Motion Axes

The Yaskawa CACR-SR10BB1BF is part of Yaskawa’s CACR-SR SERVOPACK family, a proven AC servo amplifier typically used with Yaskawa U/US-series servomotors. From my experience, this model is a solid fit for legacy machines where you need dependable velocity or torque control and straightforward pulse-train positioning without adding a fieldbus. You might notice that it keeps commissioning simple: analog command capability, terminal-based I/O, and encoder feedback wiring most maintenance teams already understand.

Company’s Order Placement Process and Guarantees

- Warranty period: 365 days

- Delivery time: typically 1 week if in stock; no more than one month at the latest

- Payment: 50% advance payment; full payment prior to delivery

- Express delivery: FedEx, UPS, DHL

Key Features

- Legacy-compatible control – Supports analog ±10 V commands for velocity/torque, making retrofits to older PLCs and motion cards straightforward.

- Pulse-train positioning – CW/CCW or A/B pulse input (typical for the CACR-SR family) for basic position control via a simple motion controller.

- Incremental encoder feedback – Line-driver feedback interface commonly used with Yaskawa U/US-series servomotors.

- Robust protection – In most cases includes overcurrent, overvoltage, and overheat alarms; helps protect the motor and drive during abnormal conditions.

- Cabinet-friendly design – Terminal-based wiring and panel mounting keep installation fast and tidy for maintenance teams.

- Serviceable architecture – Components and terminal layouts are familiar to technicians, reducing downtime during swaps or diagnostics.

Technical Specifications

| Brand / Model | Yaskawa CACR-SR10BB1BF (AC Servo Drive / SERVOPACK) |

| HS Code | 8504.40 (Static converters – AC servo drive) |

| Power Requirements | 200 V class AC supply, 50/60 Hz (verify exact rating on the unit nameplate for your revision) |

| Operating Temperature | Typically 0–45 °C in a ventilated cabinet (non-condensing) |

| Signal I/O Types | Analog ±10 V (velocity/torque), pulse-train input (CW/CCW or A/B), digital I/O for enable/alarms, incremental encoder feedback |

| Communication Interfaces | Terminal-based I/O; no fieldbus (e.g., no EtherCAT/PROFIBUS on this series) |

| Installation Method | Panel/cabinet mount, vertical orientation, front-termination wiring |

| Dimensions & Weight | Varies by production revision; please confirm from datasheet or nameplate before panel layout |

Application Fields

This drive shows up a lot in retrofit and service projects where the machine base is still mechanically sound. Typical uses include:

- Packaging and labeling lines needing velocity loops with simple indexing

- CNC retrofits on older machine tools where analog commands are standard

- Semiconductor and electronics handlers with pulse-train positioning

- Printing, converting, and winding where tight speed regulation is key

- General materials handling axes (feeders, pick-and-place, inspection stages)

One thing I appreciate is how predictable these units are when dropped into an existing cabinet. A customer in food packaging told us they swapped a failed unit with a CACR-SR10BB1BF over a weekend and were running by Monday—no rework on the PLC ladder, just a bit of tuning and it was stable.

Advantages & Value

- Reliability – Proven hardware that, in many cases, keeps legacy equipment productive without a full re-engineer.

- Compatibility – Works with standard analog commands and incremental encoders commonly found on older Yaskawa servo systems.

- Cost control – Avoids the ripple effects of upgrading entire motion platforms; faster return to service.

- Supportability – Straightforward diagnostics and readily understood I/O make maintenance efficient.

Installation & Maintenance

- Cabinet environment – Mount vertically in a clean, dry control cabinet with adequate ventilation. Keep ambient within the specified range and allow top/bottom clearance for airflow.

- Power & grounding – Use a dedicated 200 V class supply with proper fusing/breakers. Bond protective earth with low impedance. Separate motor power from signal wiring to minimize noise.

- Shielding & routing – Shield encoder and command cables; ground shields at the drive side as typically recommended. Avoid parallel runs with high-voltage lines.

- Braking and regeneration – Some applications require an external regenerative resistor; size and connect per the Yaskawa manual for your load profile.

- Tuning & checks – Perform basic gain tuning after installation. Verify enable/ready signals, direction, and encoder phasing before production.

- Routine maintenance – Periodically clean filters and cabinet dust, check terminal tightness, inspect fans (if fitted), and review alarms. Firmware on this series is typically fixed, so focus on mechanical and electrical upkeep.

Quality & Certifications

- Manufacturer certifications commonly seen on this series include CE and UL/cUL. Availability can vary by production year and regional variant.

- RoHS compliance may not apply to older legacy units; confirm per serial and production date if this is critical for your site.

- Warranty: 12 months (365 days) from shipment.

Compatible/Supporting Components (Typical)

- Yaskawa U/US-series AC servomotors (incremental encoder type)

- Motor power cable and encoder feedback cable matched to motor/drive pinout

- External regenerative resistor (when required by duty cycle)

- Line reactor or EMI filter (as needed to meet site power quality/EMC requirements)

If you’re replacing an existing unit, sharing a photo of the nameplate and your motor model helps confirm supply voltage, I/O style, and whether a regen resistor is needed. That typically shortens commissioning and avoids surprises.

Reviews

There are no reviews yet.